CIGS (Copper Indium Gallium Selenide)-based thin film solar cell and preparation method thereof

A thin-film solar cell, prefabricated layer technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of low cell conversion efficiency and unsatisfactory light absorption layer crystallization, and achieve the effect of high photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

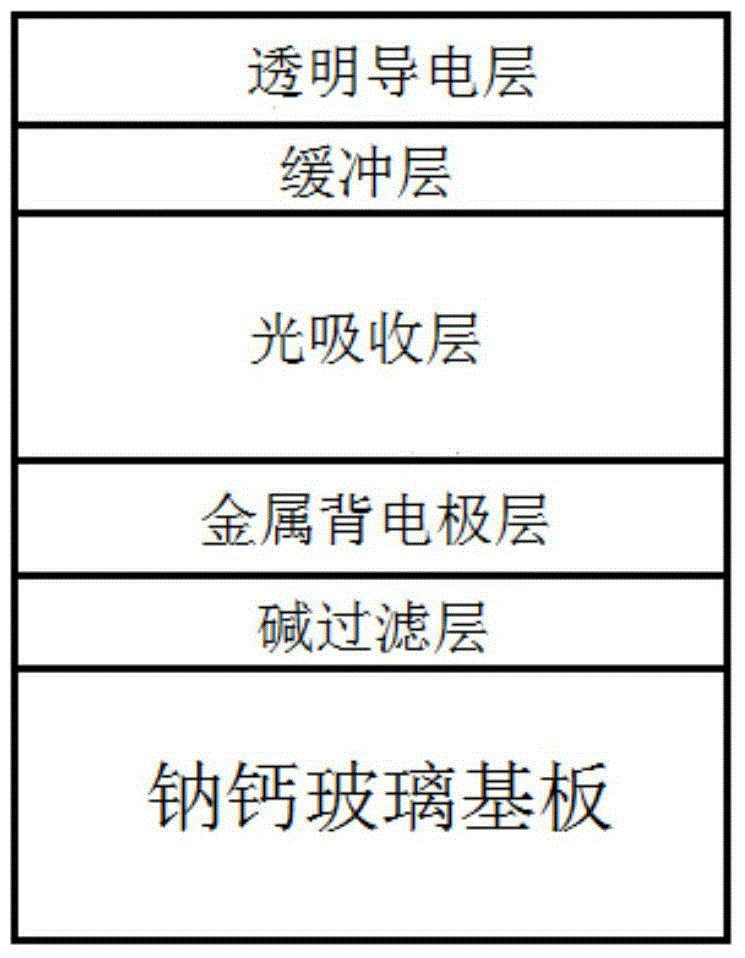

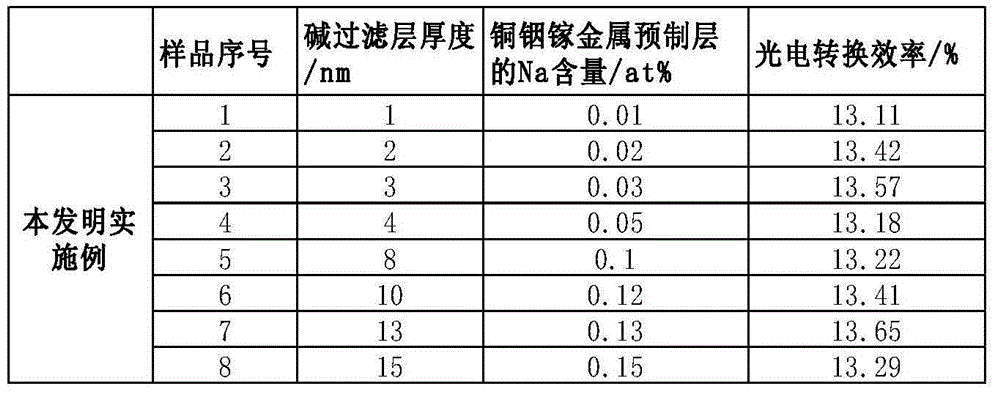

[0026] One deck of LiOa-AlOb-SiOc alkali filter layer (a=0.5, b=1.5, c=2) containing 0.005wt% Li is sputter deposited on the soda-lime glass substrate surface, and in the alkali filter layer, Si:Al=9: 1 (mass ratio), then sputter-deposit a 500nm molybdenum back electrode layer on the alkali filter layer, then deposit a copper indium gallium metal prefabricated layer containing Na on the molybdenum back electrode layer, and then send the sample into a heating furnace for selenization Heat treatment to form a light-absorbing layer, then deposit a 40nm cadmium sulfide film in a water bath on the light-absorbing layer, then deposit a 50nm ZnO film on the cadmium sulfide layer, and then deposit a 600nm AZO transparent conductive film on the ZnO film. The results of Example 1 of the present invention are shown in Table 1 below.

[0027] Table 1

[0028]

Embodiment 2

[0030]LiOa-AlOb-SiOc alkali filter layer (a=0.45, b=1.4, c=1.9) containing 5wt% Li is deposited on the surface of soda-lime glass substrate by sputtering, and Si:Al=9:1 in the alkali filter layer (mass ratio), then sputter-deposit a 500nm molybdenum back electrode layer on the alkali filter layer, then deposit a copper indium gallium metal prefabricated layer containing Na on the molybdenum back electrode layer, and then send the sample into a heating furnace for selenization heat treatment , forming a light absorbing layer, then depositing a 40nm cadmium sulfide film layer in a water bath on the light absorbing layer, then depositing a 50nm ZnO film layer on the cadmium sulfide layer, and then depositing a 600nm AZO transparent conductive film layer on the ZnO film layer. The results of Example 2 of the present invention are shown in Table 2 below.

[0031] Table 2

[0032]

Embodiment 3

[0034] LiOa-AlOb-SiOc alkali filter layer (a=0.5, b=1.5, c=2) containing 1wt% Li is sputter deposited on the surface of soda-lime glass substrate, and Si:Al=9:1 in the alkali filter layer (mass ratio), then sputter-deposit a 500nm molybdenum back electrode layer on the alkali filter layer, then deposit a copper indium gallium metal prefabricated layer containing Na on the molybdenum back electrode layer, and then send the sample into a heating furnace for selenization heat treatment , forming a light absorbing layer, then depositing a 40nm cadmium sulfide film layer in a water bath on the light absorbing layer, then depositing a 50nm ZnO film layer on the cadmium sulfide layer, and then depositing a 600nm AZO transparent conductive film layer on the ZnO film layer. The results of Example 3 of the present invention are shown in Table 3 below.

[0035] table 3

[0036]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com