Dowel bar with combined structure for cement concrete pavements and durable stitch contracting structure

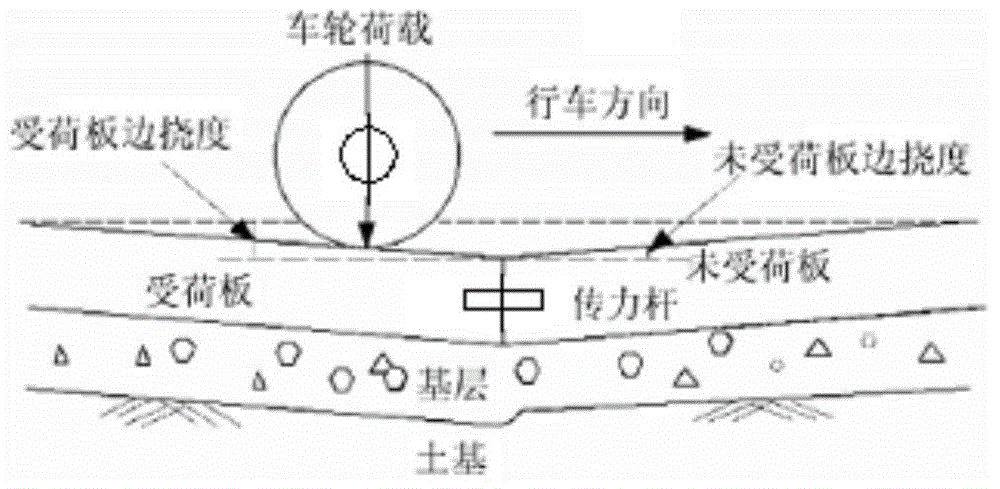

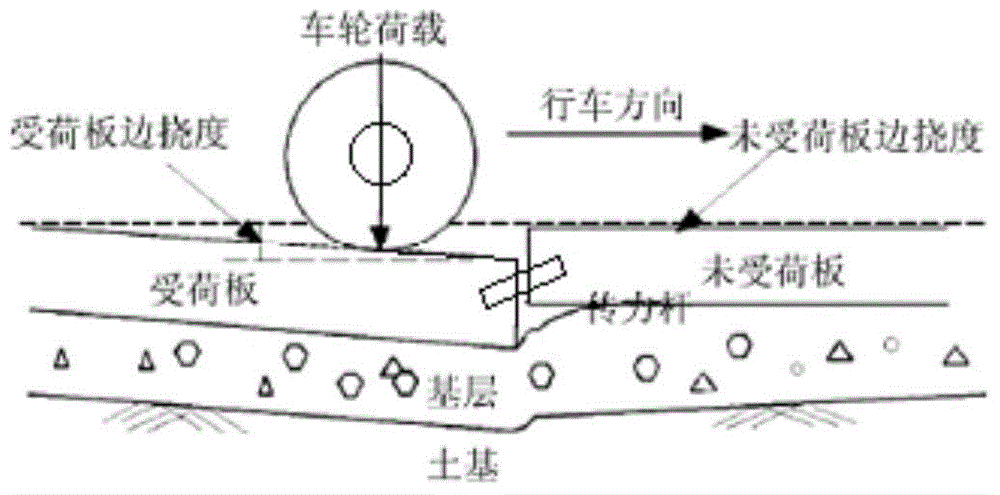

A cement concrete and composite structure technology, applied in the directions of roads, roads, pavement details, etc., can solve the problem of weakening the ability to transmit loads and resisting vertical displacement changes, the loss of expansion and contraction of the shrinkage joints of the cement concrete pavement, and the obstruction of the free end of the dowel rod. Shrinkage and other problems, to achieve excellent shear strength and deformation coordination ability, good section shear performance, improve the overall shear performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described further in conjunction with accompanying drawing and embodiment now:

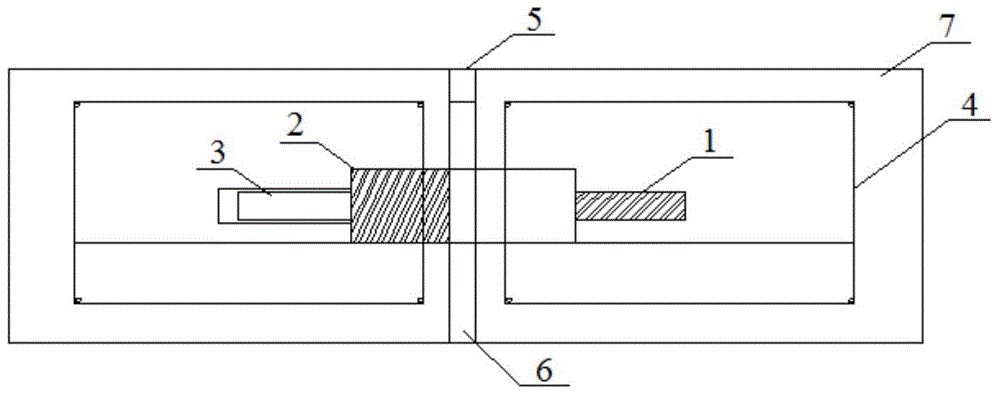

[0021] The combined structure dowel bar of the present invention mainly includes a steel dowel bar 1, a glass fiber reinforced plastic casing 2 and a polyethylene film 3, and in addition, the cement concrete pavement shrinkage joint structure also includes a dowel bar bracket 4, a joint filler 5, and a caulking plate 6 and cement concrete slab7.

[0022] In the combined structure dowel bar of the present invention, the glass fiber reinforced plastic sleeve 2 is a circular section hollow pipe body made of glass fiber reinforced plastic (GFRP). The inner wall of the glass fiber reinforced plastic sleeve 2 is smooth, and the outer surface is composed of two parts. One side of the outer surface of the casing 2 has a ribbed thread, which is firmly connected with the edge of the cement concrete slab 7, and the other side has a smooth outer surface, which can freely e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com