Air filter paper and preparation method thereof

An air filter paper and paper fiber technology, applied in the field of nanomaterials, can solve the problems of small membrane area, harsh conditions, unfavorable industrialization promotion, etc., and achieve the effects of low cost, strong adhesion, and no pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

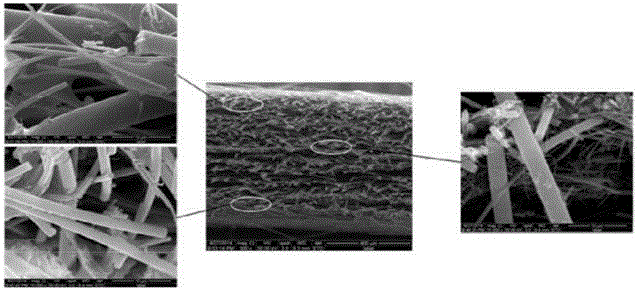

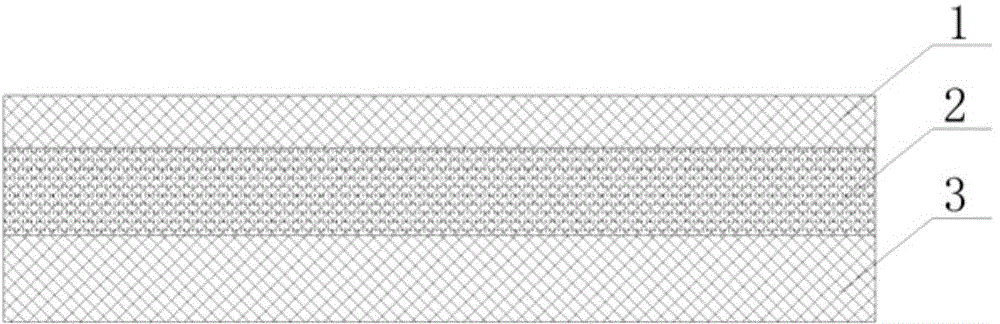

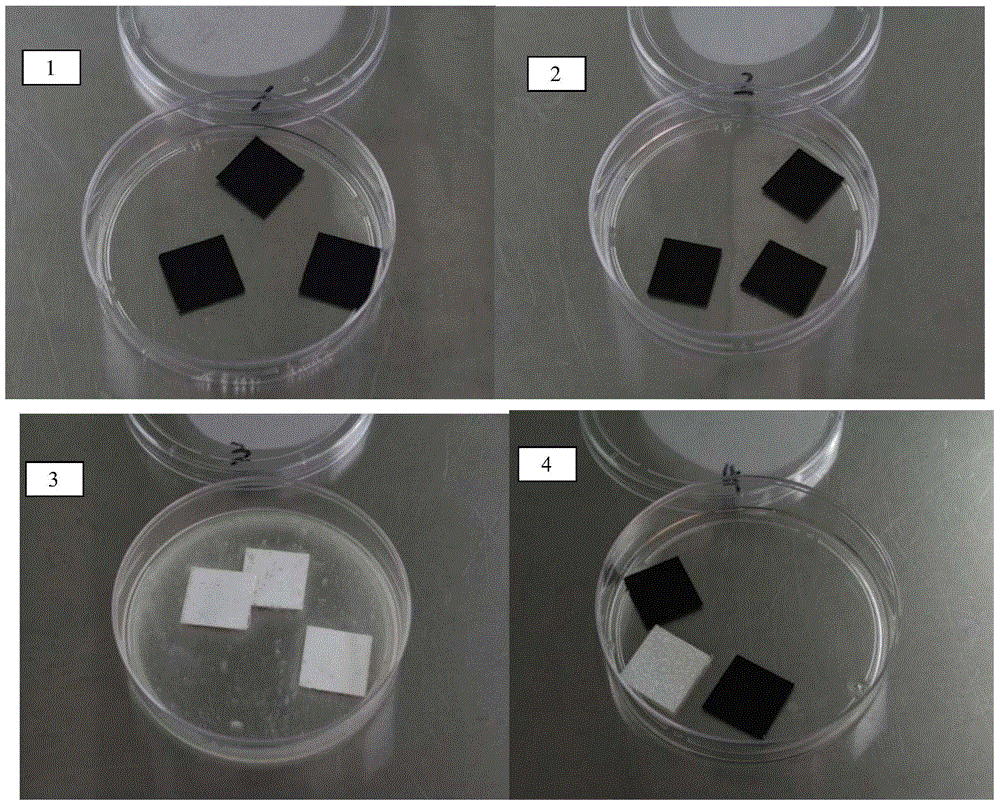

Image

Examples

Embodiment 1

[0043] A kind of preparation method of air filter paper of the present embodiment, comprises the steps:

[0044] (1) Preparation of bottom paper

[0045] After mixing polyester fiber, glass fiber, and cellulose fiber in a ratio of 3:4:3, add water and lightly beat to obtain a pulp suspension; then add water to dilute the bottom fiber suspension to a mass concentration of 0.1%, and then mix the bottom fiber The suspension is sent to the forming machine for molding, and the formed wet paper is obtained by suction; then polyacrylamide adhesive (the amount of sizing is 0.1%) is applied, and the wet paper for sizing is sucked and dried by infrared to obtain the bottom paper ;

[0046] (2) Preparation of carbon nanomaterial dispersion mixture

[0047] After mixing polyester fibers and glass fibers in a ratio of 4:1, add water to beat to obtain a pulp suspension, dilute the suspension to a mass concentration of 0.1%, and obtain a surface fiber suspension; take single-walled carbon ...

Embodiment 2

[0053] A kind of preparation method of air filter paper of the present embodiment, comprises the steps:

[0054] (1) Preparation of bottom paper

[0055] After mixing polyester fiber and glass fiber at a ratio of 1:1, add water to beat to obtain a pulp suspension; then add water to dilute to a mass concentration of 0.01% to obtain a bottom fiber suspension, and then send the diluted suspension to the former Molding, suction to obtain molding wet paper; then apply pure polyethylene adhesive (the amount of sizing is 0.5%), suck and sizing the wet paper, and then use infrared drying to obtain the bottom paper;

[0056] (2) Preparation of carbon nanomaterial dispersion mixture

[0057] After mixing polyester fibers and glass fibers in a ratio of 2:1, add water to beat to obtain a pulp suspension, dilute the suspension to a mass concentration of 0.2%, and obtain a surface fiber suspension; take carbon nanofibers with an average diameter of 200nm and add them to the mass The conce...

Embodiment 3

[0064] A kind of preparation method of air filter paper of the present embodiment, comprises the steps:

[0065] (1) Preparation of bottom paper

[0066] After mixing glass fiber, tencel fiber and polyvinyl alcohol in a ratio of 8:1:1, add water to make pulp to obtain a pulp suspension; then add water to dilute to a mass concentration of 0.3% to obtain a bottom fiber suspension, and then dilute the diluted The suspension is sent to the forming machine for molding, and the formed wet paper is obtained by suction; then polyacrylamide adhesive (the sizing amount is 0.1%) is applied, and the bottom paper is obtained by infrared drying after suction and sizing of the wet paper;

[0067] (2) Preparation of carbon nanomaterial dispersion mixture

[0068] After mixing aramid fibers and glass fibers in a ratio of 1:1, add water and beating to obtain a pulp suspension, dilute the suspension to a mass concentration of 1%, and obtain a surface fiber suspension with a maximum diameter of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com