Functional polymer containing phosphorylcholine and polyethylene glycol and construction method of antifouling coating thereof

A polymer, nitrophenoxyformyl methacrylate technology, used in coatings, biocide-containing paints, antifouling/underwater coatings, etc., to achieve broad biocompatibility and good flexibility The effect of the property and hydrophilicity, stable and firm coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1: Preparation of active ester polymerizable monomer NPCEMA

[0044]

[0045] Weigh 4.009 g of HEMA and 3.110 g of TEA in a 100 mL three-necked bottle, add 20 mL of chloroform to dissolve them, and stir mechanically. Weigh 7.434 g of NPC in a round-bottomed flask, dissolve it with 35 mL of chloroform, and add it dropwise to the above-mentioned three-necked flask to react for 4 h. Precipitate with anhydrous ether to remove triethylamine hydrochloride, recover the supernatant and concentrate, wash three times with pH 3~4 phosphate buffer solution, and dry calcium chloride powder. The solvent was removed to obtain the product NPCEMA as a white solid, 7.287 g. CDCl 3 in solvent 1 H-NMR confirmed the structure of the product with a purity of 96%.

Embodiment 2

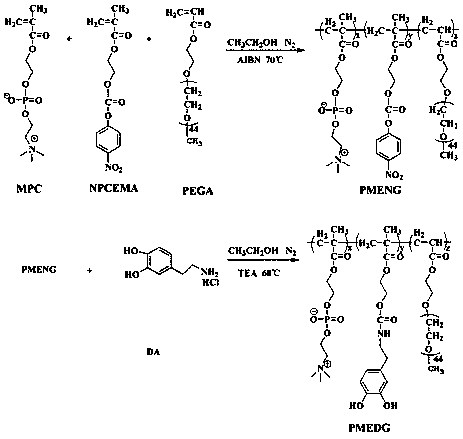

[0046] Embodiment 2: Contain the preparation of active ester functional polymer PMENG

[0047] The reaction process is as figure 1shown. Add 10 mL of absolute ethanol into a 100 mL three-necked flask, pass through nitrogen, stir with a magnetic force and gradually raise the temperature to 70 °C. Weigh 0.140 g of NPCEMA, 2.726 g of PEGA and 0.805 g of MPC in turn, and add 34 mL of absolute ethanol to dissolve them. Weigh 0.037 g AIBN and add it to the monomer mixture. Use the dropping funnel to drop the mixed solution of the monomers, and the dropwise addition is completed in about 2 h. Change to a closed system and allow it to continue to react for 24 h. After the reaction was stopped, part of the reaction solution was taken out and put into a dialysis bag with a molecular weight cut off of 7000, and dialyzed in an acidic aqueous solution with a pH of 3~4. Freeze dried. D. 2 O solvent 1 H-NMR characterizes its structure, and it is composed of polymer PMENG with 12% act...

Embodiment 3

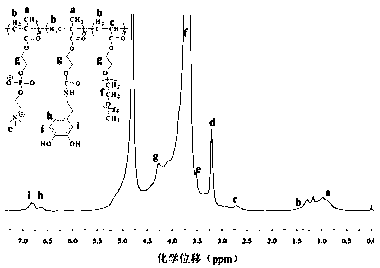

[0048] Example 3: Grafting dopamine PMEDG, introducing a catechol group with adhesion function through the reaction of active ester and amino group

[0049] Continue to pass nitrogen in the three-necked flask of the previous step reaction, and gradually raise the temperature to 60°C in the oil bath. Weigh 0.145 g of dopamine into the above-mentioned three-neck flask, add 20 mL of ethanol, and adjust the pH of the reaction solution to about 7 with triethylamine, and react for about 12 h. Adjust the reaction solution to acidity, stop the nitrogen flow, transfer it to a dialysis bag with a molecular weight cut off of 7000, and dialyze it with an acidic aqueous solution with a pH of 3~4 for 3 days. Freeze dried. D. 2 O solvent use 1 H-NMR characterizes its structure. like figure 2 shown. The molar content of catechol groups, phosphorylcholine groups and polyethylene glycol chains were 8%, 64% and 28% copolymer PMEDG respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com