Treatment system for industrial oily wastewater

A technology for treating system and wastewater, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as affecting the survival of aquatic organisms, hindering the growth of crops, blocking soil voids, etc. Achieve the effect of low noise, convenient management and improved removal ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

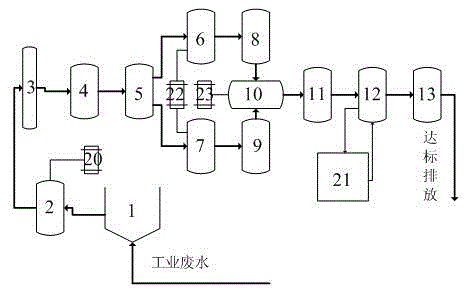

[0020] A treatment system for industrial oily wastewater, the system includes a reservoir 1, a grease trap 2, a fine grid 3, a primary sedimentation tank 4, a regulating tank 5, a first bacterial digestion tank 6, a second bacterial digestion tank 7, First aeration buffer tank 8, second aeration buffer tank 9, sludge retention tank 10, high temperature and high pressure tank 11, MBR tank 12, emergency pool 13, backwash room 21, automatic dosing device 22, oil storage tank 20. Mud storage tank 23; industrial oily waste water is connected to the inlet of reservoir 1 through pipelines, and the water outlet of reservoir 1 is connected to the water inlet of grease trap 2 through pipelines, and the oil outlet of grease trap 2 is connected to storage tank 2 through pipelines. The oil inlet of the oil tank 20, the water outlet of the grease trap 3 are connected to the water inlet of the fine grid 3 by the pipeline, the water outlet of the fine grid 4 is connected to the water inlet of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com