Vehicular wheel out-of-roundness detection method

A vehicle-mounted, wheel technology, applied in the direction of rim measurement/measurement, can solve the problems of inability to detect wheel out-of-roundness, occupying a long turnaround time, low efficiency, etc., and achieve the effect of improving the standstill operation method, reducing the cost, and making the device light and convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

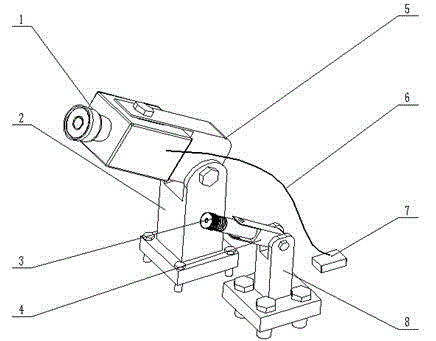

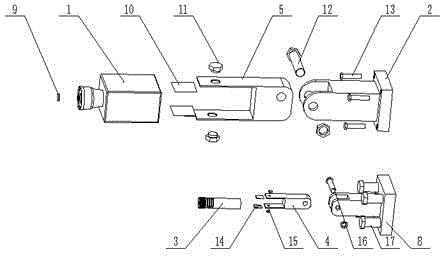

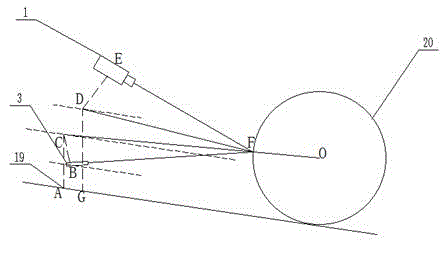

[0017] Embodiment 1. A vehicle-mounted method for detecting out-of-roundness, which consists of a semiconductor laser, a laser bracket, a laser support seat, and a laser gasket; wherein: the semiconductor laser (3) passes through the laser bracket (4), the laser support seat (8) Installed at the bottom of the side frame (18) of the steering gear, the semiconductor laser (3) has small volume, low energy consumption, good monochromaticity of emitted laser light, high brightness and strong anti-interference ability. A laser with an exit pupil power of 20mw is selected. The distance between the laser installation position and the rail surface is about 100mm AC, so that the laser is free from ballast. The working distance BF of the semiconductor laser (3) is about 600mm. The plane BCF where the laser is located is coplanar with the plane BCFO, so that the line light source can irradiate the tire part of the wheel along the radial direction of the wheel, forming a light section curv...

Embodiment 2

[0018] Embodiment 2. A vehicle-mounted method for detecting out-of-roundness, consisting of an ultra-high-speed area array CCD camera, a filter, a camera bracket, a camera support seat, and a camera gasket; wherein: the high-speed area array CCD camera (1) passes through the camera The bracket (5) and the camera support seat (2) are installed at the bottom of the side frame (18) of the steering gear, and the running speed of an ordinary train is about 120km / h, that is, it takes 3x10 hours to travel 1mm. -5 s, the high-speed area array CCD camera (1) can use Phanton v710 monochrome CCD, which can achieve 7500 frames / s image acquisition under the full-scale 1024×800 pixels, and the maximum can be achieved by reducing the number of recorded pixels (reducing the spatial resolution). Up to 700,000 frames / s, that is, the camera needs 1.43 x10 -6 s, which can meet the error requirement that the width of the light section curve is less than 1mm. The camera is adjusted to the interlace...

Embodiment 3

[0019] Embodiment 3. A vehicle-mounted method for detecting out-of-roundness, which is composed of a relay module and a locomotive control room; wherein: the relay module (7) is composed of a single-chip microcomputer and a digital transmission station, and the relay module is fixed on the bogie The bottom of the side frame (18) is connected to the high-speed area array CCD camera (1) through the data transmission line (6). The format is saved in the specified location in the hard disk, and then the image in the hard disk is processed by image processing software to obtain the real shape curve of the wheel.

[0020] Working method of the present invention is as follows:

[0021] Before testing the wheel out-of-roundness, preparations must be made. The operator checks whether the semiconductor laser and the high-speed area array CCD camera are normal. After the train stops, install the vehicle-mounted out-of-roundness detector on the bottom of the side frame of the bogie. . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com