Method for monitoring safety performances of batteries and capacitors on line

A technology of safety performance and capacitors, which is applied in secondary batteries, electrochemical generators, secondary battery repair/maintenance, etc., can solve the problems of non-destructive online detection of battery and capacitor safety performance, etc., to make up for the lack of real-time safety supervision, Make up for the lack of technology and the effect of high application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Multi-channel dynamic resistance strain gauges are used to monitor the safety performance of batteries of different shapes and battery packs in real time for a long time during operation. The schematic diagram of the distribution of foil strain gauges on batteries of different shapes and battery packs is as follows figure 1 As shown, the strain gauges are pasted on the intersection of the face angles of the square battery and the equivalent position on the surface, and the strain gauges are pasted on the center and edge equivalent positions of the circular battery, and the upper, middle, lower positions and edges of the cylindrical battery, etc. The strain gauges are pasted on the effective position, and the battery pack is pasted with strain gauges on the side of each battery. The specific implementation steps are as follows: 1) Strain gauge selection: According to the test requirements, select the foil resistance strain gauge, the strain limit does not exceed 50%, and ...

Embodiment 2

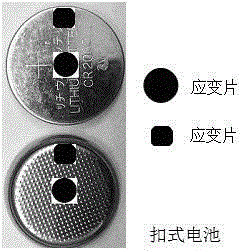

[0025]A multi-channel distributed static resistance strain test is used to monitor the gas safety performance of the button battery during operation. The distribution diagram of the strain gauges on the button battery is shown in figure 2 As shown in Φ0.02~0.05mm constantan wire strain gauge is used to monitor the safety of the button battery, and the strain gauge is firmly bonded to the equivalent position of the center and edge of the button battery through a thin layer of epoxy resin. , in order to ensure insulation, the strain gauge can be sealed, dried with an infrared lamp, the temperature of the bonding surface is controlled not to exceed 40oC, the strain gauge is connected to the computer through the strain gauge for real-time safety performance monitoring, other bonding and testing processes As in Example 1.

Embodiment 3

[0027] Monitoring LiNi Using Strain Tests 1 / 3 co 1 / 3 mn 1 / 3 o 2 The safety performance of soft-packed batteries at room temperature and 80oC flatulence, the distribution of strain gauges on square soft-packed batteries is shown in image 3 As shown, the safety of the square flexible packaging battery is monitored by using Φ0.01~0.03mm nickel-chromium aluminum alloy strain gauges at room temperature and high temperature respectively. At high temperature, temperature compensation is used to slightly scrape the bonding parts of the aluminum-plastic film surface of the flexible packaging to ensure the safety of the battery. Increase the roughness of the surface, firmly bond the strain gauge to the equivalent position of the center and edge of the square battery and the two electrode leads, dry naturally for 15~20h to cure, and connect the strain gauge to the computer through the strain gauge after passing the inspection Real-time safety performance monitoring is carried out, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com