Multi-stage soft recovery method for high-speed test projectiles and auxiliary device thereof

An auxiliary device, soft recovery technology, applied in the direction of ammunition testing, ammunition, offensive equipment, etc., can solve problems such as huge investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

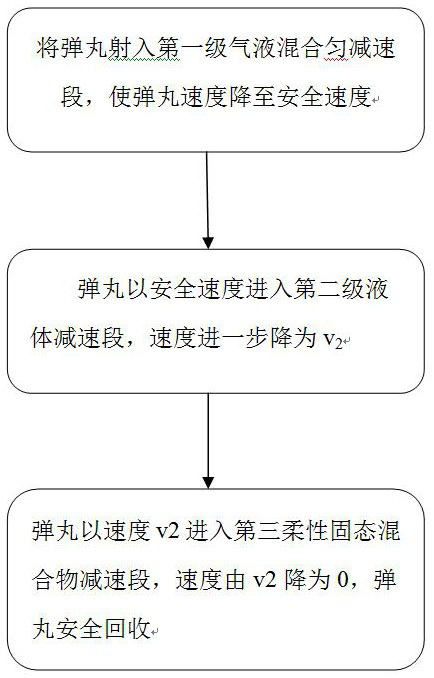

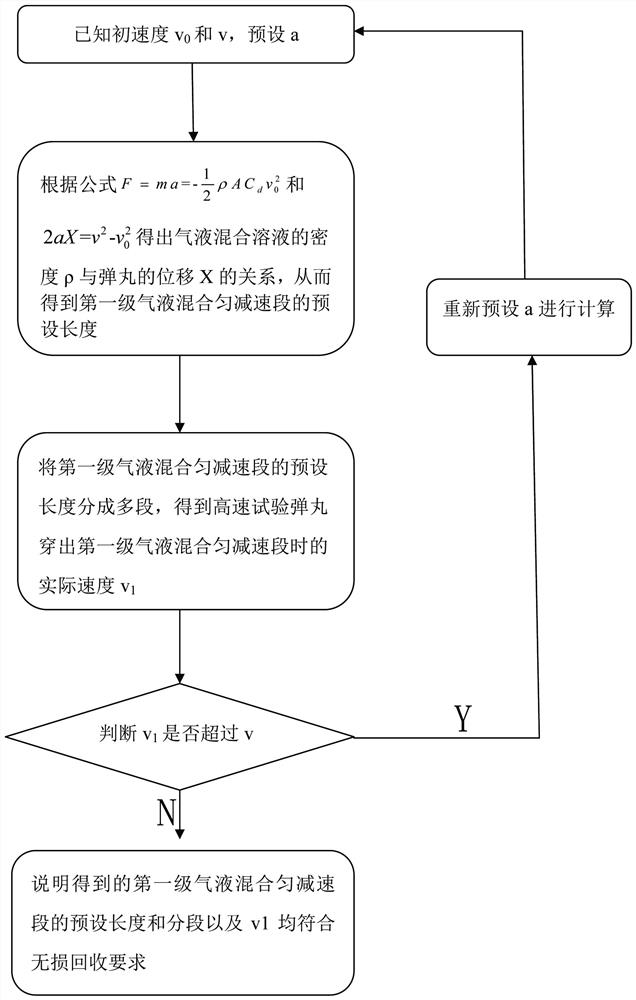

[0036] Embodiment 1: A kind of multi-stage soft recovery method of high-speed test projectiles, the high-speed test projectiles are injected into the first-stage gas-liquid mixing uniform deceleration section, the second-stage liquid deceleration section and the third-stage flexible solid mixture deceleration section sequentially, with Realize the non-destructive recovery of high-speed test projectiles; figure 1 and figure 2 As shown, the method includes the following steps:

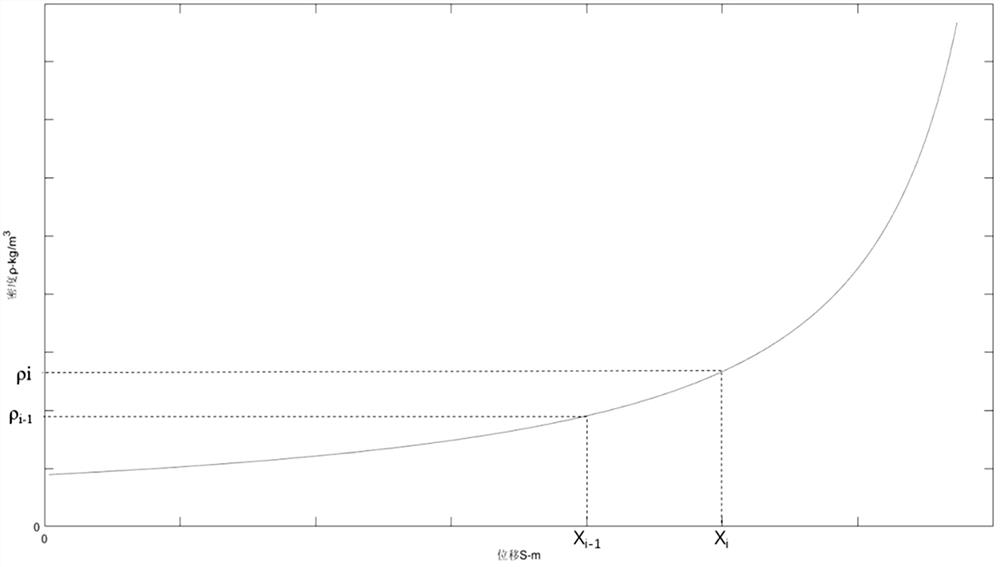

[0037] Step 1: Inject the high-speed test projectile into the first-stage gas-liquid mixing deceleration section. When the high-speed test projectile is not injected into the first-stage gas-liquid mixing deceleration section, the deceleration speed of the high-speed test projectile is 0m / s 2 , the initial velocity v when the high-speed test projectile is injected into the first-stage gas-liquid mixing uniform deceleration section is measured by a high-speed camera 0 is 1500m / s, and the length of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com