A measuring device for the coaxiality of internal and external sleeve teeth in a box body

A technology for measuring devices, inner and outer jackets, applied to measuring devices, instruments, etc., can solve problems such as difficult calculation and compensation, measurement, and bulky measuring devices, and achieve the effects of improving assembly efficiency, simple and fast operation, and reducing hardware requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following describes the present invention in more detail with reference to the drawings and embodiments:

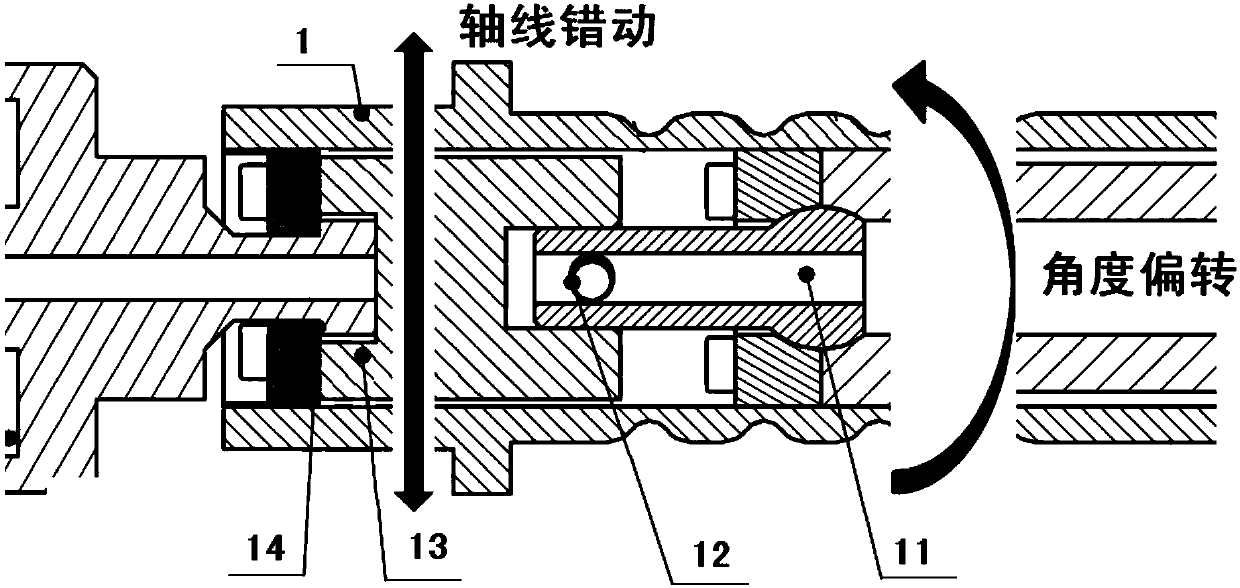

[0020] See attached figure 1 Shown is the installation diagram of the spline shaft between the flight attachment receiver and the aircraft body. When installing the aircraft attachment receiver case and the fuselage body, a spline shaft is required to connect the flight attachment receiver gear and the aircraft internal gear. One end of the spline shaft needs to extend into the inside of the attached casing to mesh with the gear of the fuselage, and the other end to mesh with the external gear of the accessory casing on the outside.

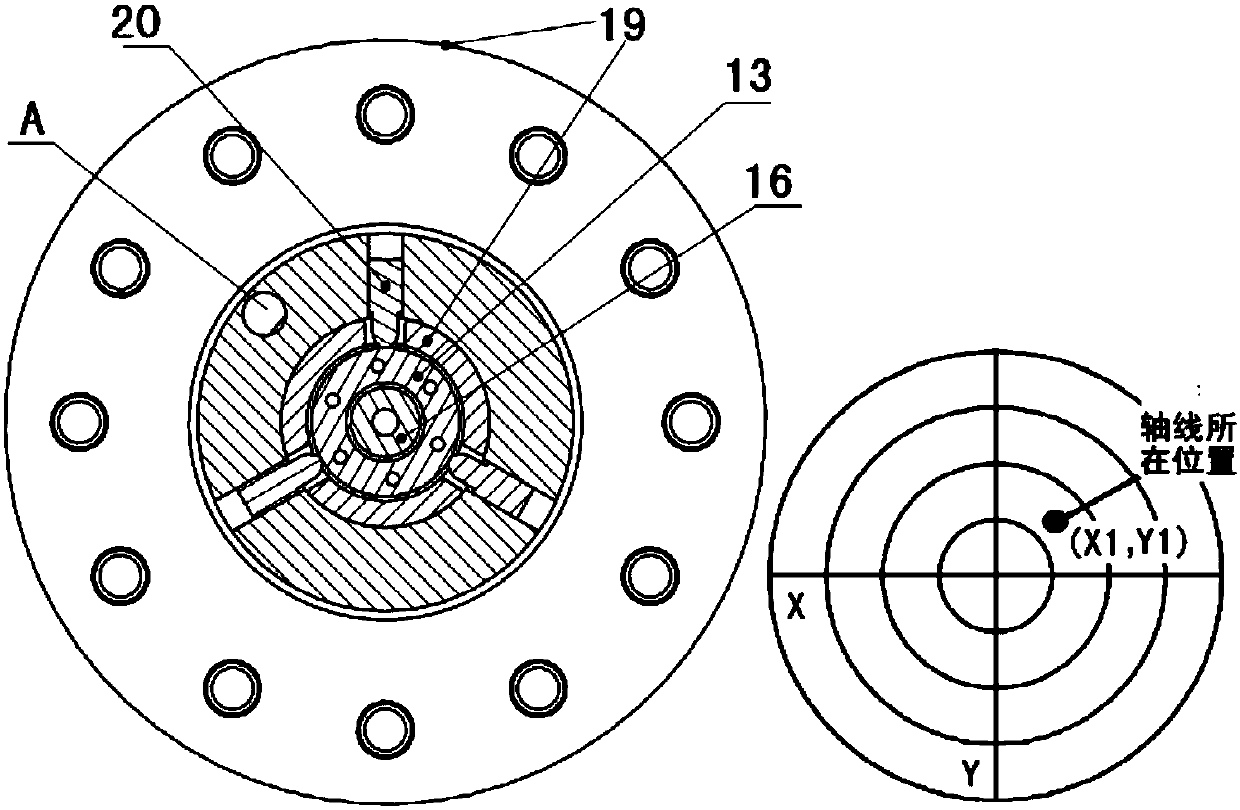

[0021] See attached Figure 5 As shown, the measuring device for the coaxiality of the outer teeth in the box includes a front mandrel 6 and a support sleeve 1. The two are supported and maintained coaxially by a dense ball bearing cage 2 and balls 8. The sliding support block 3 is installed in the groove at the front end of the cage 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com