Graphene/silicon photodetector with passivated interface and preparation method thereof

A graphene and silicon photoelectric technology, applied in the field of photoelectric detection, can solve problems such as complex manufacturing processes, achieve low cost, increase photoelectric voltage, and facilitate promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

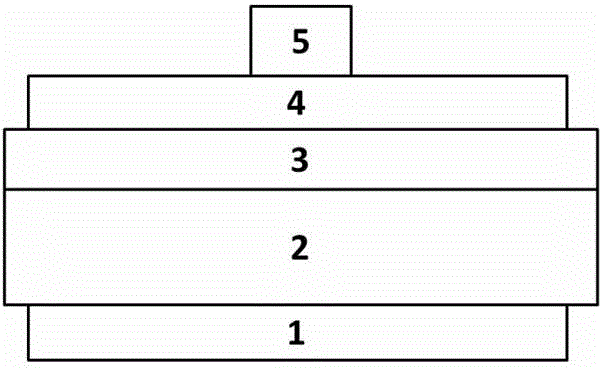

[0019] 1) Clean the p-type doped silicon substrate with a resistivity of about 1Ω·cm without damage on the surface, and dry it;

[0020] 2) A 0.2nm aluminum oxide layer is grown on one side of the silicon substrate using atomic layer deposition technology;

[0021] 3) Transfer single-layer graphene onto the alumina layer;

[0022] 4) Fabricate InGa alloy electrodes on the back of the silicon substrate;

[0023] 5) Coating silver paste on graphene and drying to obtain interface passivated graphene / silicon photodetector.

Embodiment 2

[0025] 1) Clean the n-type doped silicon substrate with a resistivity of about 1Ω·cm without damage on the surface, and dry it;

[0026] 2) A 1nm aluminum oxide layer is grown on one side of the silicon substrate using atomic layer deposition technology;

[0027] 3) Transfer 10 layers of graphene onto the alumina layer;

[0028] 4) Deposit gold electrodes on the back of the silicon substrate by thermal evaporation;

[0029] 5) A chromium-nickel composite electrode was deposited on graphene by magnetron sputtering to obtain an interface passivated graphene / silicon photodetector.

Embodiment 3

[0031] 1) Clean the n-type doped silicon substrate with a resistivity of about 10Ω·cm without damage on the surface, and dry it;

[0032] 2) A 10nm aluminum oxide layer is grown on one side of the silicon substrate using atomic layer deposition technology;

[0033] 3) Transfer 5 layers of graphene onto the alumina layer;

[0034] 4) Deposit titanium-palladium-silver composite electrodes on the back of the silicon substrate by electron beam evaporation;

[0035] 5) Deposit gold electrodes on graphene by magnetron sputtering to obtain interface passivated graphene / silicon photodetectors.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com