Preparation for hollow graphite carbon ball/manganese dioxide nano-fiber composite material

A nanofiber, manganese dioxide technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of poor conductivity and unsatisfactory capacitance performance of manganese dioxide, and achieve low cost, It is beneficial to the transmission of electrons, and the operation method is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

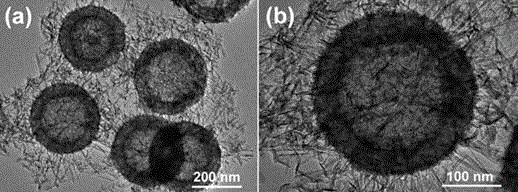

[0022] 1. Deposit carbon on the surface of spherical silica with a size of about 200nm by chemical vapor phase method, and further graphitize at 90 degrees, and then dissolve the silica with 20% HF. Obtained hollow graphite carbon spheres.

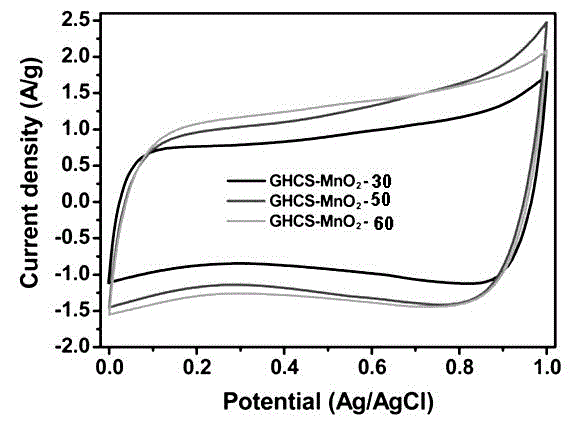

[0023] 2. Put graphite carbon spheres in potassium permanganate solutions of different concentrations (20%, 30%, 50%), reflux at 70 degrees for 2 hours, then filter, wash with ethanol three times, and dry in an oven at 90 degrees. Finally, hollow graphite carbon sphere / manganese dioxide nanofiber composites with different manganese dioxide contents (30%, 50%, 60%) were obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com