A lithium ion battery diaphragm with a heat closing function, preparation method and application thereof

A technology for lithium ion batteries and separators, which is applied in the field of lithium ion battery separators with thermal closing function and their preparation, can solve the problem that the high temperature thermal stability and hygroscopic performance of the separator cannot meet the requirements, and the thermal stability and safety performance are not improved. The performance is not guaranteed and other problems, to achieve the effect of increasing the affinity/liquid retention performance, improving the high temperature thermal stability, and increasing the apparent density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

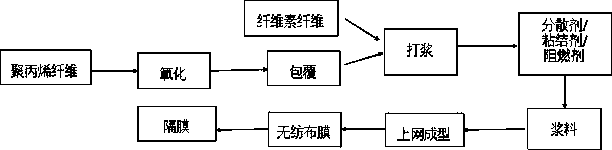

[0040] The present invention also provides a preparation method for the above-mentioned lithium-ion battery diaphragm, comprising the steps of:

[0041] Oxidizing polypropylene fibers to obtain hydrophilic polypropylene fibers;

[0042] Mixing the hydrophilic polypropylene fiber, xylene, acrylic acid, initiator and modifying agent to obtain modified polypropylene fiber;

[0043] Dissolving the modified polypropylene fibers and cellulose fibers in water for beating to obtain a slurry;

[0044] Dehydrating and drying the slurry to obtain a non-woven fabric film by hot pressing;

[0045] The non-woven membrane is heat-treated to obtain a lithium-ion battery separator.

[0046] The invention oxidizes the polypropylene fiber to obtain the hydrophilic polypropylene fiber.

[0047] In the present invention, the reagent for oxidation is preferably an acidic potassium permanganate solution, and the concentration of the acidic potassium permanganate solution is preferably 5% to 10%, ...

Embodiment 1

[0062] 1) Wash the polypropylene fiber with acetone, remove oil and dry it, put it in a 5% acidic potassium permanganate solution, and heat it in a water bath at 70°C for 10 minutes to obtain hydrophilic polypropylene fiber;

[0063] 2) After swelling 1Kg of hydrophilic polypropylene fiber with 5Kg of xylene and 5Kg of acrylic acid, add 0.01Kg of initiator benzoyl peroxide and 1Kg of modifier calcium carbonate for stirring to obtain modified polypropylene fiber;

[0064] 3) Soak 110g of bamboo fiber and 90g of modified polypropylene fiber in 5L of water for 6 hours, pressurize and beat the cellulose fiber to obtain a slurry with a beating degree of 60°, and then measure the moisture content of the slurry;

[0065] 4) Add 3g of dispersant polyacrylamide and 10g of binder polyhexafluoroethylene to the slurry, add water to dissolve, disperse and mix evenly;

[0066] 5) The slurry obtained in step 4 was dehydrated through a copper mesh, pressed, then dried, and hot-pressed at 120°...

Embodiment 2

[0069] 1) Wash the polypropylene fiber with acetone, remove oil and dry it, put it in an 8% acidic potassium permanganate solution, and heat it in a water bath at 80°C for 15 minutes to obtain hydrophilic polypropylene fiber;

[0070] 2) After swelling 1Kg of hydrophilic polypropylene fiber with 5Kg of xylene and 5Kg of acrylic acid, add 0.01Kg of initiator benzoyl peroxide and 1Kg of modifier calcium carbonate for stirring to obtain modified polypropylene fiber;

[0071] 3) Soak 110g of acetate fiber and 100g of modified polypropylene fiber in 5L of water for 6 hours, pressurize and beat the cellulose fiber to obtain a slurry with a beating degree of 70°, and then measure the moisture content of the slurry;

[0072] 4) Add 0.5g dispersant polyethylene oxide and 5g binder polyhexafluoroethylene to the slurry, then add water to dissolve and disperse the fibers and mix them evenly;

[0073] 5) The slurry obtained in step 4 is dehydrated through a copper mesh, pressed, then dried...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture size | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com