Ultrasonic water meter flow calibration standard device

A flow verification and standard device technology, which is applied in measuring devices, testing/calibrating devices, liquid/fluid solid measurement, etc., can solve problems such as poor stability, large flow fluctuations, feedback signal interference, etc., and achieve high stability and environmental changes The effect of small influence and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

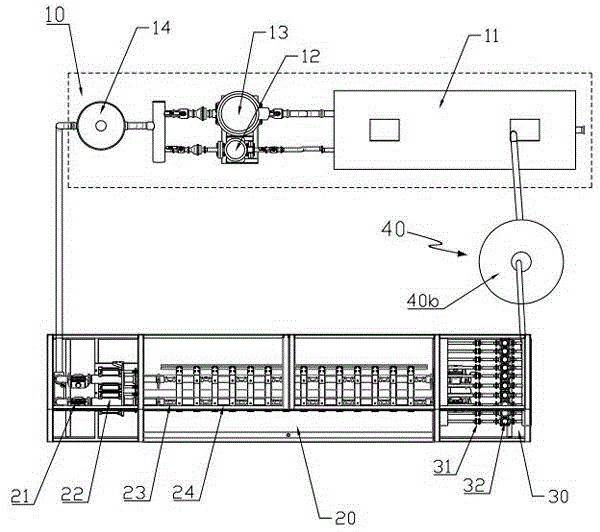

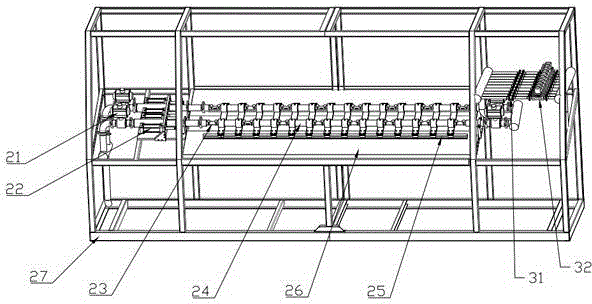

[0026] Embodiment 1: see figure 1 , the standard volume device 40 is a volume tank 40b, and the constant pressure water supply system 10, the ultrasonic water meter detection platform 20 and the standard volume tank 40b are sequentially connected circularly to form a water circulation system. The tank body of the standard volume tank 40b has a standard volume scale. The water flow enters from the top of the tank body and flows out from the bottom into the water tank 11 of the constant pressure water supply device 10, which is used for calibrating the ultrasonic water meter.

[0027] see figure 2 , wherein the constant pressure water supply system 10 includes a water tank 11, two water pumps 12, 13 and a surge tank 14, the water tank 11 is respectively connected to the two water pumps 12, 13 through a manual ball valve 15, and the two water pumps are respectively connected to two A different check valve 16 is connected to the surge tank 14 afterward. Among them, the volume o...

Embodiment 2

[0030] Embodiment 2: There is usually a standard volume device for verifying ultrasonic water meters in the flow identification standard device, such as the standard volume tank or electronic scale weighing water tank in Embodiment 1. In order to maintain the measurement accuracy of the ultrasonic water meter, it is necessary to select a standard volume tank with higher measurement accuracy. However, the volume tank with high measurement accuracy is very sensitive to environmental changes. Temperature, humidity, buoyancy or deformation of the tank will affect the measurement accuracy. Electronic scales Also have above-mentioned defective. Therefore, see Figure 5, in Embodiment 2 of the present invention, an annular volumetric tube 40a is used instead of a standard volumetric tank 40b to calibrate the flow rate of the ultrasonic water meter, and the annular volumetric tube 40a is arranged between the constant pressure water supply system 10 and the ultrasonic water meter detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com