Rotary drilling rig main winch system based on energy recovery of energy accumulator

An energy recovery, rotary drilling rig technology, applied in the direction of winch, spring mechanism, fluid pressure actuation system components, etc., can solve problems such as reducing the service life of hydraulic components, consuming large engine power, and increasing system heat load. , to achieve the effect of improving energy utilization, reducing heat loss and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

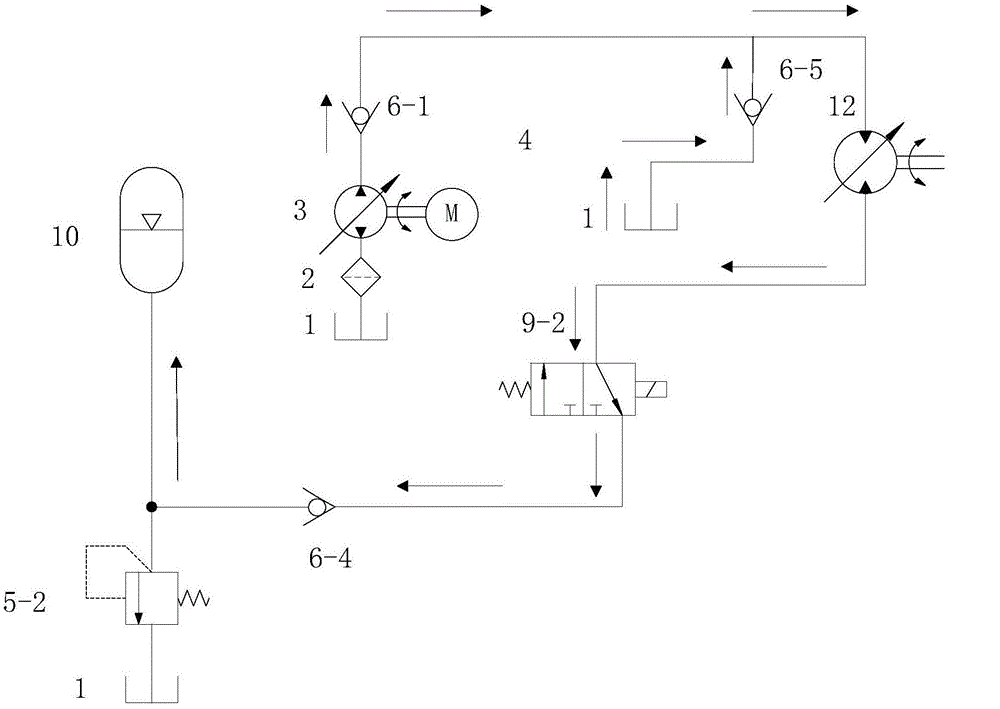

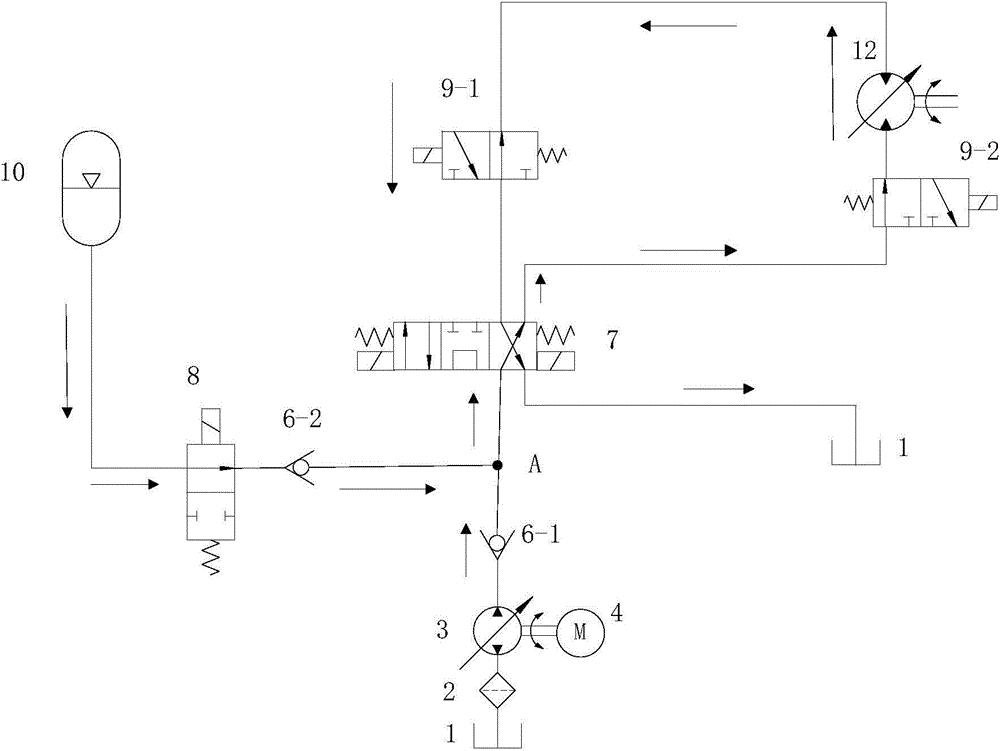

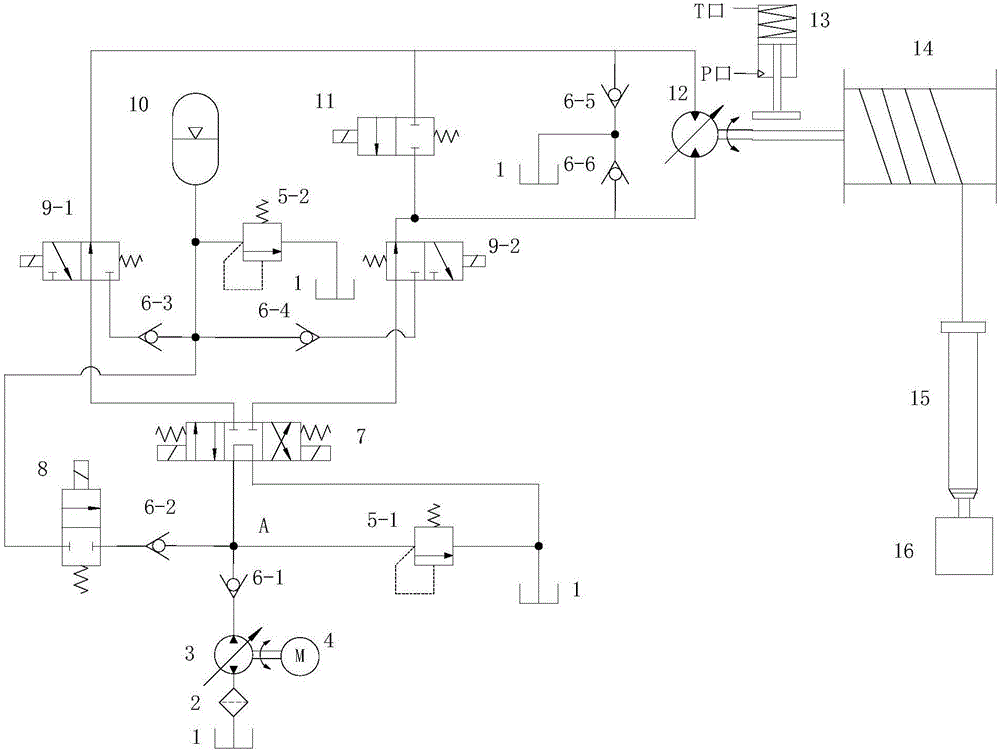

[0021] see image 3 , the present invention includes motor 4, hydraulic pump 3, oil filter 2, oil tank 1, accumulator 10, main winch motor 12, brake cylinder 13, reel 14, drill pipe 15, drilling tool 16, first overflow Flow valve 5-1 and second overflow valve 5-2, float valve 11, confluence valve 8, main electromagnetic reversing valve 7, first energy recovery valve 9-1 and second energy recovery valve 9-2 and first One-way valve 6-1, second one-way valve 6-2, third one-way valve 6-3, fourth one-way valve 6-4, fifth one-way valve 6-5 and sixth one-way valve 6- 6. The main electromagnetic reversing valve 7 is sequentially connected to the first one-way valve 6-1, the first energy recovery valve 9-1, the second energy recovery valve 9-2, and the first fuel tank 1-1; the accumulator 10 is sequentially Connected to the second overflow valve 5-2, the third one-way valve 6-3, the fourth one-way valve 6-4, the confluence valve 8; the first energy recovery valve 9-1 and the second en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com