A method of producing ectoine by high-density culture of recombinant escherichia coli

A technology for recombining Escherichia coli and ectoine, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as increasing the difficulty of downstream purification processes, equipment corrosion, and complex components of fermentation products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Example 1, Construction of Escherichia coli ectoine high-yield strain BW-pBAD-ectABC

[0070] (1) Expression of ectoine synthesis gene cluster EctABC in Escherichia coli

[0071] 1. PCR amplification of the coding sequence of the ectoine synthesis gene cluster EctABC

[0072] Using the genomic DNA of Halomonas elongate (CGMCC No.1.6329) as a template, PCR amplification was performed with primers EctABC-P1 and EctABC-P2 to obtain PCR amplification products.

[0073] EctABC-P1: 5'-CCTA GCTAGC ATGAACGCAACCACAGAGCCCTTTA-3'

[0074] EctABC-P2: 5'-CCG CTGCAG TTACAGCGGCTTCTGGTCGTCGGCT-3'

[0075] 2. Digestion and ligation

[0076] The PCR amplified product was double-digested with NheI and PstI, and ligated with the pBAD / HisA plasmid large fragment previously cut with NheI and PstI to obtain a recombinant plasmid.

[0077] 3. Transformation, screening and sequence verification

[0078] Transform the recombinant plasmid prepared above into Escherichia coli DH5α by calc...

Embodiment 2

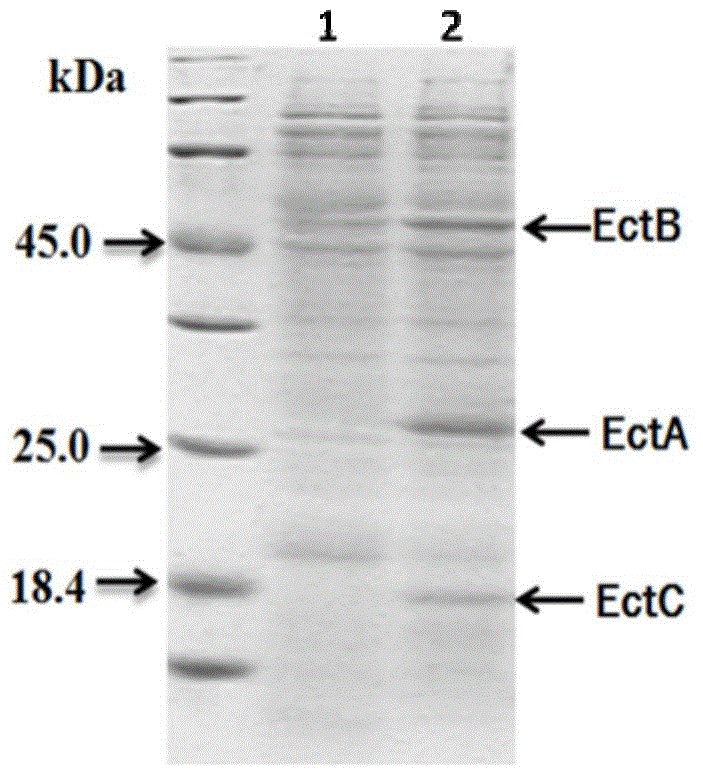

[0081] Embodiment 2, the expression of EctABC gene in Escherichia coli ectoine high-yield strain BW-pBAD-ectABC

[0082] Pick a single colony of BW-pBAD-ectABC and inoculate it into 5 ml of LB medium containing ampicillin (100 μg / ml), and culture overnight at 37°C. Inoculate 1ml of the overnight culture into 100ml of LB medium containing ampicillin (100μg / ml) and culture at 37°C with vigorous shaking (200rpm) to the OD of the fermentation broth 600 When the value reaches about 0.6-0.8, add L-arabinose to the fermentation system (the final concentration of L-arabinose is 1g / L), and continue to cultivate at 30°C for 6 hours. Escherichia coli BW-pBAD containing empty vector was set as negative control.

[0083] After fermentation, centrifuge at 5000rpm for 15 minutes to collect the bacteria; resuspend the bacteria in PBS buffer with pH 7.0, and centrifuge at 12,000rpm for 15min after ultrasonication. Collect the supernatant, which is the crude enzyme solution containing the tar...

Embodiment 3

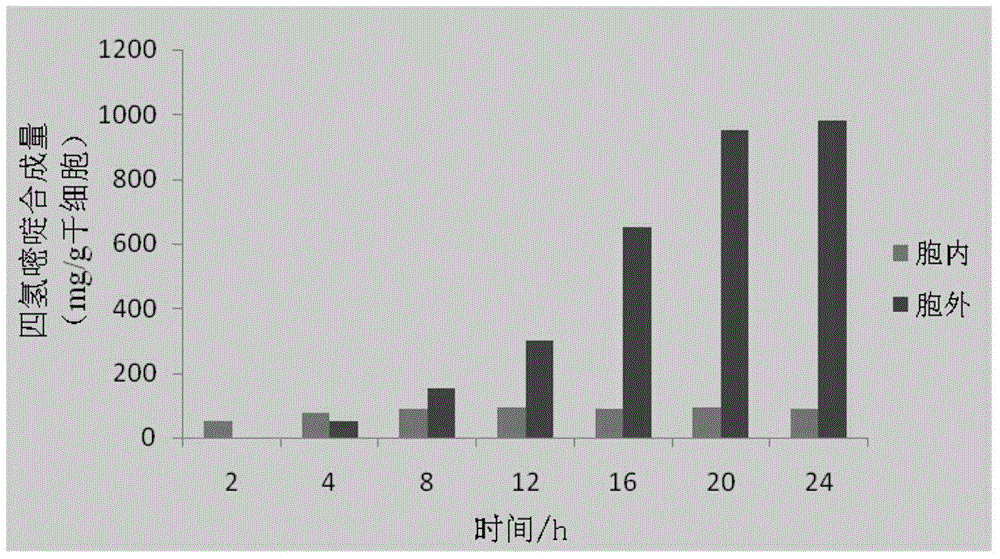

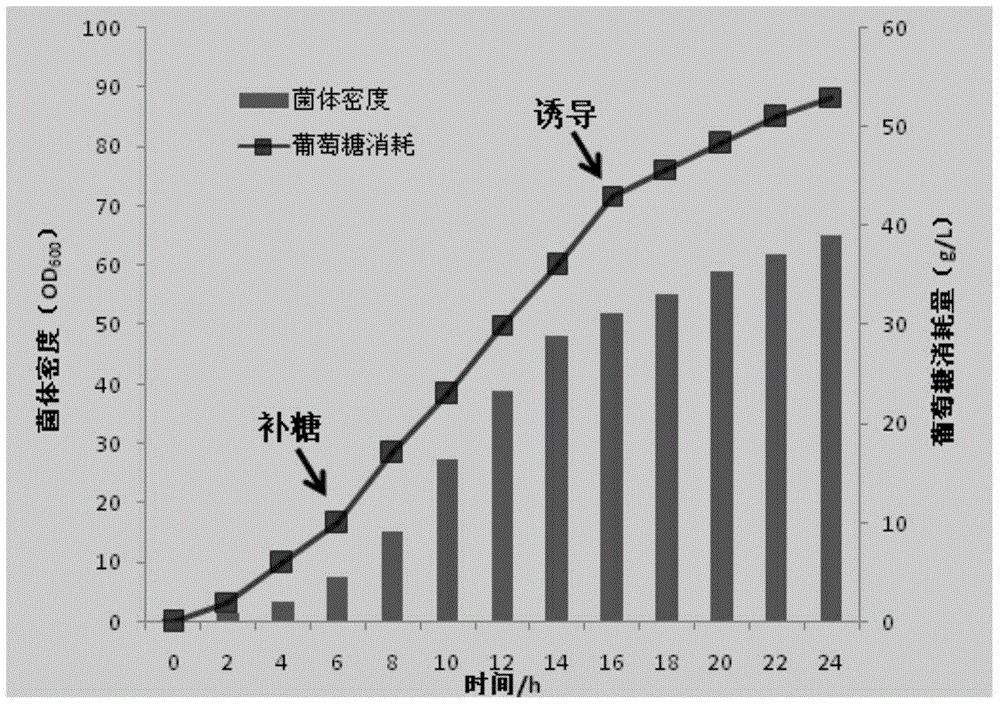

[0084] Example 3, the application of the strain BW-pBAD-ectABC with better ectoine synthesis ability and the preservation number is CGMCC NO.8334

[0085] (1) Preparation of ectoine by strain fermentation and biotransformation

[0086] 1. Strain fermentation and expression of EctABC gene

[0087] Pick a single colony of BW-pBAD-ectABC and insert it into 20ml of LB medium containing ampicillin (100μg / ml), and culture overnight at 37°C. Inoculate 5ml of the overnight culture into 500ml LB medium containing ampicillin (100μg / ml) and culture at 37°C with vigorous shaking (200rpm) to the OD of the fermentation broth 600 When the value reaches about 0.6-0.8, add L-arabinose to the fermentation system (the final concentration of L-arabinose is 1g / L), continue to cultivate at 30°C for 6 hours and centrifuge at 5000rpm for 15 minutes to collect the bacteria.

[0088] 2. Biotransformation reaction

[0089] After centrifugation, the cells were added to the transformation medium, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry cell weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com