Operating method for vulcanized hydrogenation catalyst

A hydrogenation catalyst, a vulcanization-type technology, which is applied in the field of start-up of a vulcanization-type hydrogenation catalyst, can solve the problems of loss of active components and decrease in catalyst activity, and achieve the effects of saving start-up time, improving hydrogenation activity, and being environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation of embodiment 1 catalyst A

[0034] Get 100g oxidation state catalyst I, pass into the mixed gas of hydrogen and hydrogen sulfide, H 2 :H 2S=4:1, heat up to 300°C for 6 hours of vulcanization, cool down and take out the catalyst to obtain a vulcanized catalyst. Spray and immerse with an aqueous solution of nickel citrate (2.5g / 100ml in terms of nickel), so that the introduced nickel citrate (in terms of nickel oxide) accounts for 0.5% of the weight of the sulfurized catalyst, and then treat it at 150°C under nitrogen protection After 6 hours, catalyst A was obtained.

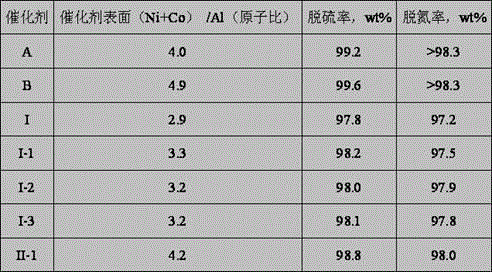

[0035] Put the catalyst A into the reactor, keep the nitrogen pressure at 3.4MPa, directly raise the temperature to 300°C, keep the temperature for 6 hours and then cool down to 280°C, replace the nitrogen with hydrogen, and introduce the raw material oil at the same time, start the hydrogenation reaction after 24 hours at the constant temperature, the reaction Samples were taken for an...

Embodiment 2

[0036] The preparation of embodiment 2 catalyst B

[0037] Take 100g of oxidation state catalyst II, pass through hydrogen, raise the temperature to 120°C and start to feed vulcanized oil, which contains CS 2 5% (v%), after constant temperature for 1 hour, continue to heat up to 230°C for 3 hours, then heat up to 320°C for 3 hours, cool down and take out the catalyst to obtain a vulcanized catalyst. Spray and immerse with an aqueous solution of cobalt citrate (concentration calculated as cobalt: 4.5g / 100ml), so that the introduced cobalt citrate (calculated as cobalt oxide) accounts for 1% of the weight of the sulfurized catalyst, and then treat it under air at 120°C for 12 hours, the catalyst B was obtained.

[0038] The start-up and reaction conditions are the same as in Example 1, and the hydrodesulfurization activity is shown in Table 2.

Embodiment 3

[0039] The preparation of embodiment 3 catalyst C

[0040] Get 100g oxidation state catalyst III, pass into the mixed gas of hydrogen and hydrogen sulfide, H 2 :H 2 S=4:1, heat up to 300°C for 6 hours of vulcanization, cool down and take out the catalyst to obtain a vulcanized catalyst. Spray and immerse with an aqueous solution of nickel citrate (2.5g / 100ml in terms of nickel), so that the introduced nickel citrate (in terms of nickel oxide) accounts for 0.5% of the weight of the sulfurized catalyst, and then treat it at 150°C under nitrogen protection After 6 hours, catalyst C was obtained.

[0041] Put the catalyst C into the reactor, start the circulating compressor after the airtightness is qualified, increase the pressure to 4.0MPa with nitrogen, raise the temperature of the catalyst bed to 300°C, keep the temperature constant for 6 hours, reduce the cracking section The inlet temperature of the inlet is up to 200°C, and then coking kerosene (nitrogen content is 0.035...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com