Long chain organic acid purifying method

An organic acid and organic phase technology, applied in the field of obtaining high-purity long-chain organic acids, can solve the problems of large solvent consumption, complicated operation process, and lack of availability, and achieve less material consumption, low energy consumption, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

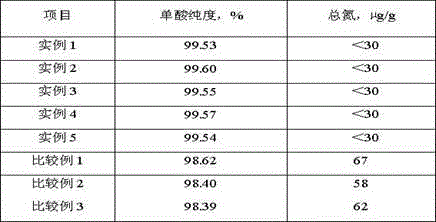

Examples

Embodiment 1

[0032] Take 200ml and get C by fermenting Candida tropicalis 12 h 22 o 4 Organic acid fermentation broth, the concentration is 160g / l. heated to 80°C with H 2 SO 4 Adjust the pH value to 3.0, let it stand for 2 hours, and remove the liquid wax remaining in the solution to obtain the C containing bacteria. 12 h 22 o 4 Organic acid crystallization solution.

[0033] C 12 h 22 o 4 Organic acid crystallization liquid and n-propyl ether (n-propyl ether and C 12 h 22 o 4The weight ratio is 7:1), and heated to 80°C. After the organic acid is dissolved, add 16 ml of cetyltrimethylammonium chloride with a mass fraction of 0.05% to the mixture, mix well, and stand still for 60 minutes. , and remove the lower water phase; then add 30ml deionized water to the solvent phase to wash the organic phase, and then separate the water phase; then add 0.3g activated carbon to the organic phase and decolorize for 30min, then filter to remove the activated carbon, and the decolorized or...

Embodiment 2

[0035] Take 200ml and get C by fermenting Candida tropicalis 12 h 22 o 4 Organic acid fermentation broth, the concentration is 160g / l. heated to 80°C with H 2 SO 4 Adjust the pH value to 3.0, let it stand for 2 hours, and remove the liquid wax remaining in the solution to obtain the C containing bacteria. 12 h 22 o 4 Organic acid crystallization solution.

[0036] C 12 h 22 o 4 Organic acid crystallization liquid and n-butyl ether (n-butyl ether and C 12 h 22 o 4 The weight ratio is 6:1), and heated to 93°C. After the organic acid is dissolved, add 6.4 ml of dodecyltrimethylammonium chloride with a mass fraction of 0.1% to the mixture, mix well, and stand still for 60 minutes. , and remove the lower water phase; then add 50ml deionized water to the solvent phase to wash the organic phase, and then separate the water phase; add 0.2g activated carbon to the organic phase and decolorize for 30min, then filter to remove the activated carbon, and the organic phase afte...

Embodiment 3

[0038] Take 200ml and get C by fermenting Candida tropicalis 13 h 24 o 4 Organic acid fermentation broth with a concentration of 154g / l. Heat to 70°C, filter through a ceramic microfiltration membrane, remove bacteria and residual liquid wax to obtain a filtrate. Add H to the filtrate 2 SO 4 Adjust the pH to 2.4 and heat to 95 °C to give C 13 h 24 o 4 The organic acid crystallization solution was cooled to room temperature and filtered to obtain an organic acid filter cake.

[0039] Put the obtained C 13 h 24 o 4 Organic acid filter cake and n-butyl ether (n-butyl ether and C 13 h 24 o 4 The weight ratio is 2:1), and heated to 97°C. After the organic acid is dissolved, add 12.5 ml of tetradecyltrimethylammonium halide with a mass fraction of 0.3% to the mixture, mix well, and stand still for 60 minutes. Separate the lower water phase; then add 60ml of deionized water to the solvent phase to wash the organic phase, and then separate the water phase; add 0.15g of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com