A butterfly plate hydraulic automatic combination device of a butterfly valve assembly machine and its combination method

A butterfly valve and automatic combination technology, which is applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems that processing and manufacturing cannot meet the demand, it is difficult to meet the needs of the market and users, and the cost of repair and maintenance is increased. , to achieve the effect of improving work efficiency and product quality, saving maintenance costs and production costs, and facilitating promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

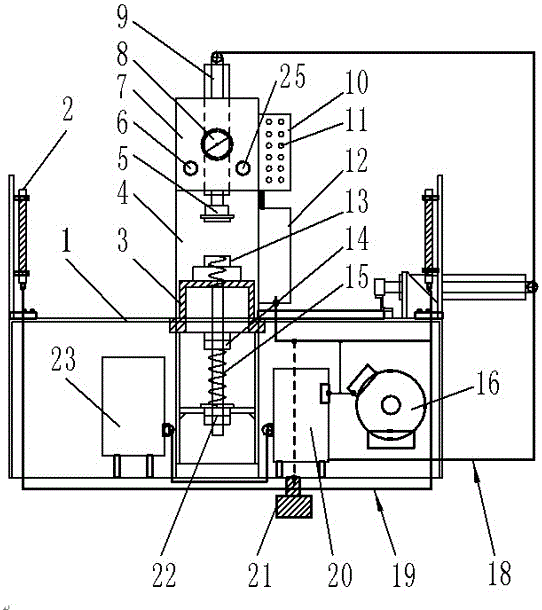

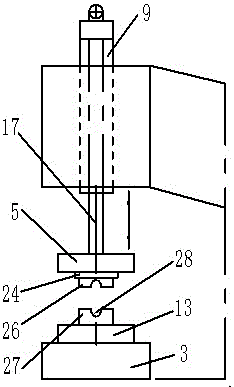

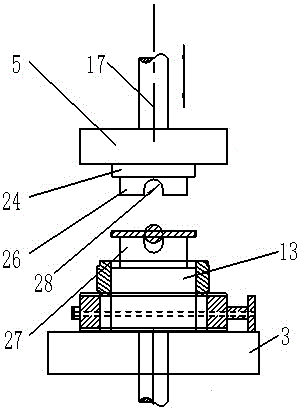

[0041] As shown in the figure, a butterfly plate hydraulic automatic combination device of a butterfly valve assembly machine consists of a butterfly valve assembly workbench 1, an infrared sensor safety device 2, a tooling base 3, an assembly machine column 4, a pressure head tooling 5, and a pressure regulating valve. Device 6, upper hydraulic cylinder support frame 7, pressure gauge 8, upper hydraulic cylinder device 9, PLC control box device 10, control button 11, electrical box device 12, butterfly valve tooling 13, lock nut mechanism 14, lower screw screw assembly Cheng 15, motor device 16, piston rod device 17, hydraulic system pipeline 18, signal system circuit 19, hydraulic pump device 20, foot switch mechanism 21, limit lock female device 22, hydraulic oil tank device 23, butterfly valve assembly retaining ring 24. The pressure gauge switch device 25, the movable pressure head device 26, the positioning pressure head device 27, the butterfly plate bushing slot 28, and...

Embodiment 2

[0053] As shown in the figure, a combination method of butterfly plate hydraulic automatic combination device of butterfly valve assembly machine, the specific process steps are as follows:

[0054] First of all, prepare for work; organize and prepare the working and operating conditions according to the management standards of the factory above 6s, and check the condition of each component of the butterfly valve assembly machine; ensure that the hydraulic oil in the hydraulic oil tank device 23 is not lower than the lower limit of the liquid level gauge, and the electrical box device The power supply of 12 is safe and normal;

[0055] Secondly, carry out the test run; open the electrical box device 12, close each switch of the machine, the power indicator light is on, start the electro-hydraulic control butterfly valve automatic assembly machine; check the steering of the motor device 16, the fan blade is set to rotate clockwise, Loosen the pressure gauge switch device 25, ad...

Embodiment 3

[0062] As shown in the figure, a combination method of butterfly plate hydraulic automatic combination device of butterfly valve assembly machine, the specific process steps are as follows:

[0063] First of all, prepare for work; organize and prepare the working and operating conditions according to the management standards of the factory above 6s, and check the condition of each component of the butterfly valve assembly machine; ensure that the hydraulic oil in the hydraulic oil tank device 23 is not lower than the lower limit of the liquid level gauge, and the electrical box device The power supply of 12 is safe and normal;

[0064] Secondly, carry out the test run; open the electrical box device 12, close each switch of the machine, the power indicator light is on, start the electro-hydraulic control butterfly valve automatic assembly machine; check the steering of the motor device 16, the fan blade is set to rotate clockwise, Loosen the pressure gauge switch device 25, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com