Particulate water-absorbing agent and process for producing same

A manufacturing method and water-absorbing agent technology, applied in particle suspension analysis, chemical instruments and methods, absorbent pads, etc., can solve problems such as unaware of long-term maintenance effects, and achieve superior absorption characteristics and superior absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

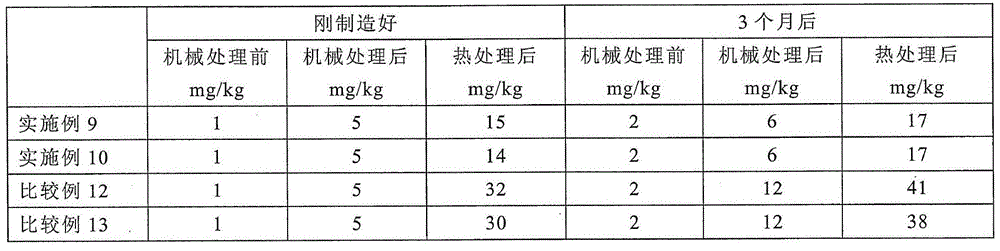

[0302] 〔5〕Example

[0303] Hereinafter, the present invention will be specifically described by way of examples and comparative examples. The electrical equipment used in the Examples and Comparative Examples were all used under the conditions of 100V and 60Hz. In addition, unless otherwise specified, all physical properties were measured under the conditions of room temperature (23°C±2°C) and relative humidity of 50%RH.

[0304] In addition, for convenience, "mass%" may be written as "wt%" and "liter" may be written as "L". In addition, in this specification, "0.90 mass % sodium chloride aqueous solution" may be referred to as "physiological saline", but both are the same substance. In addition, in the following columns (5-1) to (5-13), "particulate water-absorbing agent" is written for convenience, but when measuring "water-absorbent resin particles" or "water-absorbent resin", etc. It is called "granular water absorbent".

[0305] (5-1) Water absorption capacity without...

manufacture example 1

[0384] A cover was attached to a double-arm type stainless steel kneader with two sigma-type stirring blades and a casing with an inner volume of 10 L to prepare a reactor, and 425.2 g of acrylic acid and a 37% by mass sodium acrylate aqueous solution were charged into the reactor. 4499.5g, 538.5g of pure water, 6.17g of polyethylene glycol diacrylate (molecular weight 523), and 0.21g of trisodium diethylenetriaminepentaacetate, thereby obtaining a reaction solution, and then carried out in a nitrogen atmosphere for 20 minutes outgassing.

[0385] Next, while stirring the reaction solution, 28.3 g of a 10% by mass sodium persulfate aqueous solution and 23.6 g of a 0.1% by mass L-ascorbic acid aqueous solution were added individually, and polymerization started about 25 seconds later. Next, while performing polymerization at 25 to 95° C., the generated hydrogel-like crosslinked polymer was ground, and 30 minutes after the start of polymerization, the hydrogel-like crosslinked p...

manufacture example 2

[0388] Change the consumption of the polyethylene glycol diacrylate (molecular weight 523) in manufacture example 1 to 4.93g, except that, all carried out the same operation with manufacture example 1, obtain weight-average particle diameter (D50) be 380 μ m . Randomly crushed water absorbent resin particles (2) having a logarithmic standard deviation (σζ) of particle size distribution of 0.33. The obtained water-absorbent resin particles (2) had a water absorption capacity under no pressure (CRC) of 45 [g / g] and a water-soluble content (Ext) of 15% by mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com