Lithium ion battery cathode active substance and manufacturing method thereof

A negative electrode active material and ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of cycle stability decline, increase irreversible capacity, etc., and achieve the effect of low temperature and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

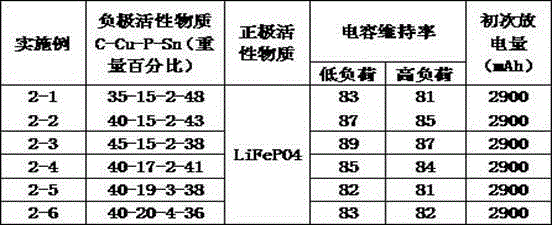

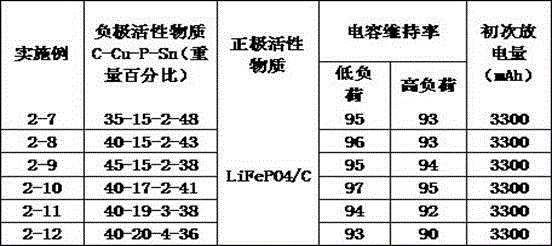

Examples

specific Embodiment 1

[0070] This embodiment is an example to prepare the positive electrode active material. First, add 0.2 moles of ferric nitrate to 200ml of deionized water to dissolve. After it is completely dissolved, add 0.2 moles of phosphoric acid, and then add 100ml of a pre-configured lithium hydroxide aqueous solution containing 0.2 moles to make the lithium ion in the solution: iron Ion: Phosphate ion by LiFePO 4 The metering ratio (1:1:1) is mixed, and after the complete mixing reaction, a metal ion containing Fe, Li + and (PO 4 ) 3- solution; and then dry the solution to obtain powdered starting material. The powdered starter is placed in an alumina crucible, and then the crucible is placed in a microwave sintering furnace with a microwave frequency of 2.45 GHz to make it burn at 700 °C under nitrogen. 0 C and processed for 0.5 hour to obtain lithium iron phosphate powder that can be used as positive electrode active material.

specific Embodiment 2

[0071] A negative electrode active material layer is fabricated. First, 35g of graphite carbon powder, 15g of copper powder, 2g of phosphorus powder and 52g of tin powder were thoroughly mixed to obtain a mixture. The lid mixture was placed in a quartz cauldron, and ground by a ball mill in nitrogen for 20 hours, thereby pulverizing it to obtain copper-phosphorus-carbon-tin powder.

specific Embodiment 3

[0072] How to make a lithium battery. First, mix the lithium iron phosphate powder prepared in Example 1 with carbon black and polyvinyl difluoride binder in proportion (83:10:7), and then cover it on a 10um aluminum foil. After 120 0 After drying at C for 6 hours, the positive electrode was obtained. And the copper-phosphorus-carbon-tin powder prepared in Example 2 is mixed with carbon black and polyvinyl difluoride binder, and the ratio of Yi (83:10:7) is evenly mixed, and then coated on a 10um aluminum foil, after 120 0 After drying at C for 6 hours, the negative electrode was obtained.

[0073] The separator layer is composed of a microporous polyethylene film of 25um and then wound up several times after being stacked in the order of negative electrode, separator layer and positive electrode. Next, mix 40 weight percent of 4-fluoro, 3-dioxolane-2-one (FEC), 45 weight percent of dimethyl carbonate (DMC), 15 weight percent of electrolyte LiPF 6 And adjust the electrolyte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com