Ultraviolet-cured polyurethane-based conductive silver paste and preparation method thereof

A conductive silver paste, polyurethane-based technology, applied in the field of electronic chemicals, can solve the problem of low photoinitiator dosage, achieve the effect of improving electrical conductivity and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Prepare UV-curable polyurethane-based conductive silver paste according to the following formula:

[0042]

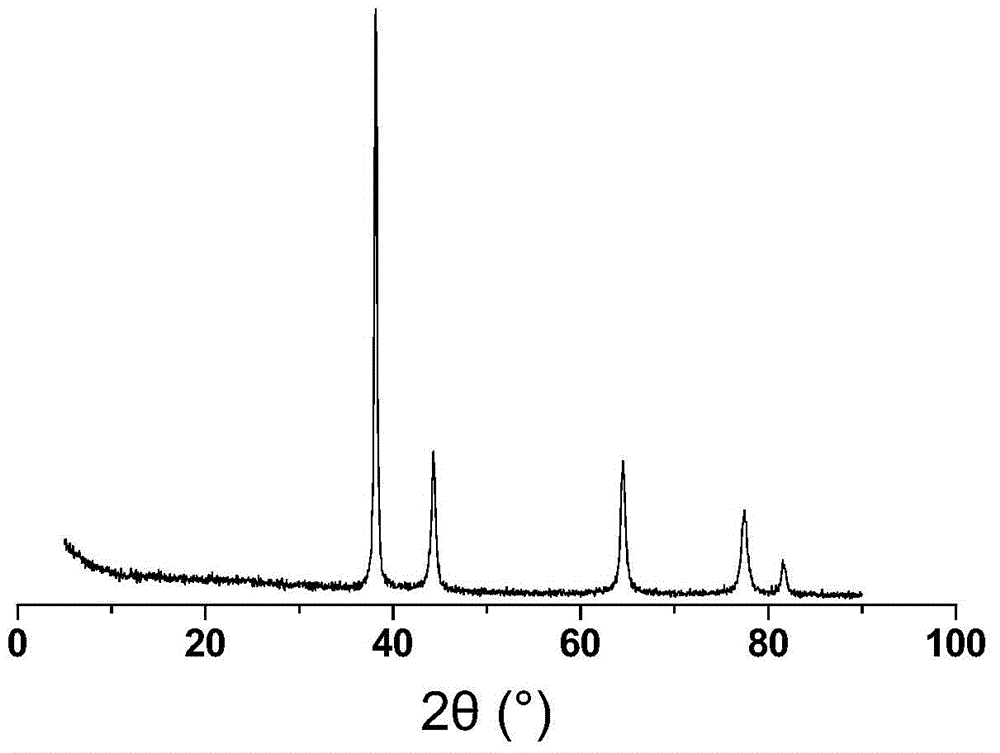

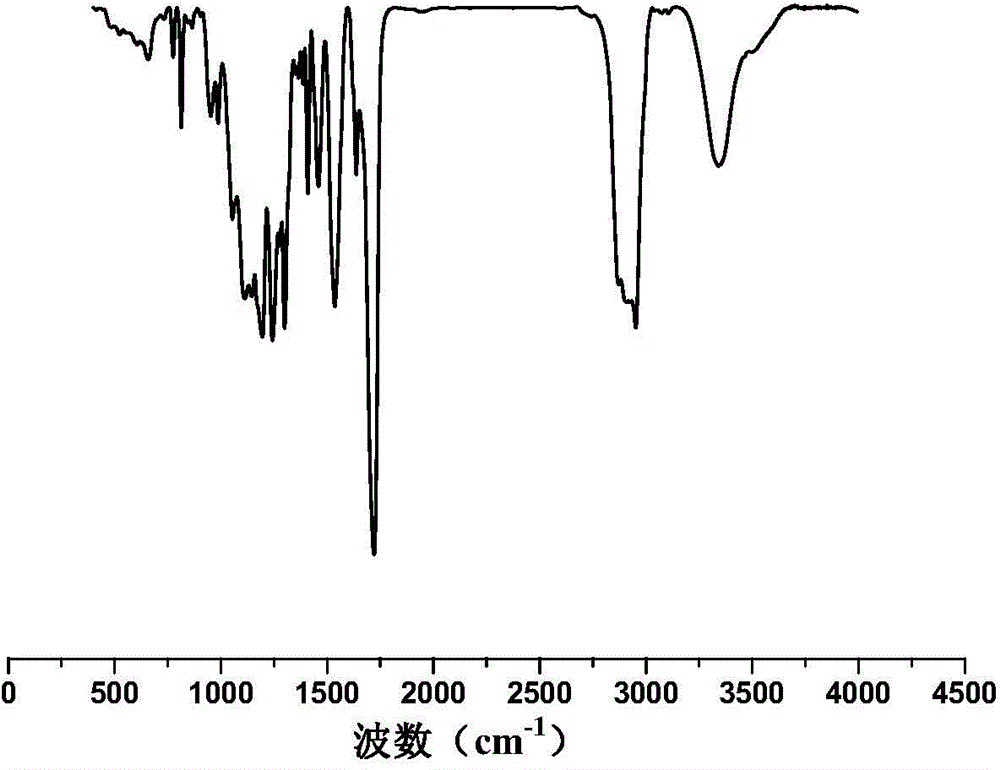

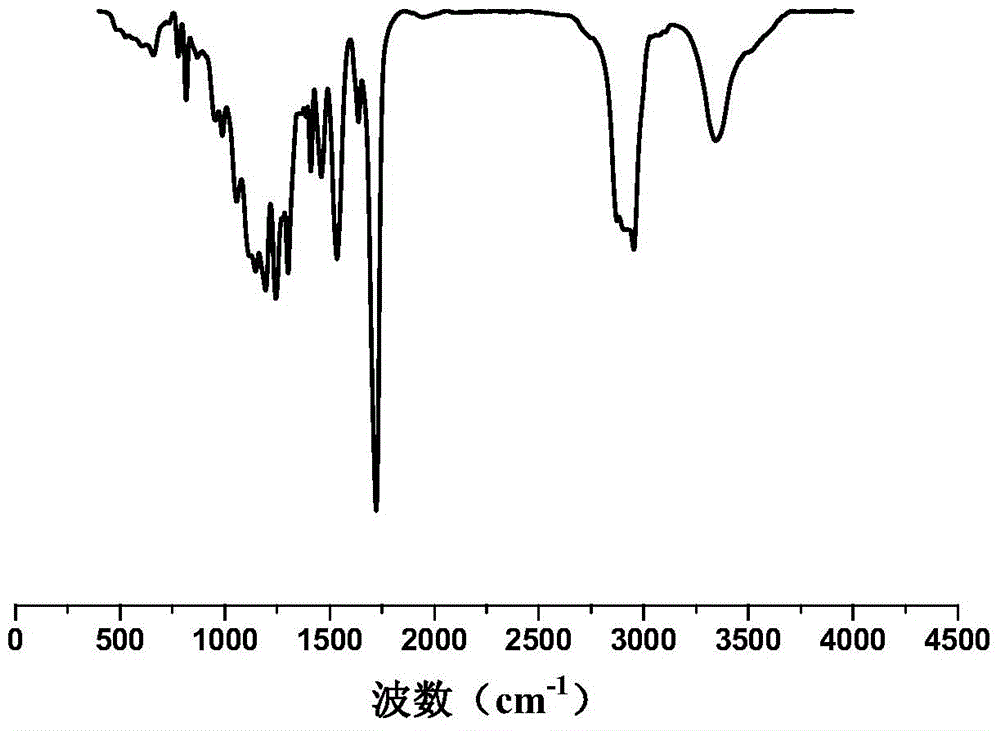

[0043] (1) Preparation of ultrafine spherical silver: 1.70g PVP, 0.50gCTAB and 1.76g ascorbic acid were dissolved in deionized water, and sodium hydroxide was added to adjust the pH to 12.5 to prepare 50ml of reducing solution; 1.70g of AgNO 3 Dissolved in deionized water and diluted to 1.0mol / L, AgNO at 300r / min 3 Add it dropwise into the reducing solution, control the dropping time to 20min, and the reaction temperature to 30°C. After the dropwise addition, continue to react for 30min; centrifuge the reacted suspension (high-speed desktop centrifuge: GT10-1, Beijing Times North Lee Centrifuge Co., Ltd.) at 10,000r / min for 30min, and the centrifuged product was washed once with deionized water, absolute ethanol and acetone; the washed ultrafine spherical silver was dried at 30°C and 0.1mmHg for 48h to prepare ultrafine The fine spherical silver powder is rea...

Embodiment 2

[0048] Prepare UV-curable polyurethane-based conductive silver paste according to the following formula:

[0049]

[0050]

[0051] (1) Preparation of ultrafine spherical silver: 1.70gPVP, 0.50gCTAB and 1.76g ascorbic acid were dissolved in deionized water, and sodium hydroxide was added to adjust the pH to 12.5, and 50ml of reducing solution was prepared; 1.70gAgNO 3 Dissolved in deionized water and diluted to 0.5mol / L, AgNO 3 Add dropwise to the reducing solution, control the dropping time to 10min, and the reaction temperature to 50°C, continue to react for 20min after the dropwise addition is completed; centrifuge the reacted suspension (high-speed desktop centrifuge: GT10-1, Beijing Times North Lee Centrifuge Co., Ltd.) at 10,000r / min for 30min, and the centrifuged product was washed once with deionized water, absolute ethanol and acetone; the washed ultrafine spherical silver was dried at 50°C and 0.1mmHg for 24h to prepare ultrafine The fine spherical silver powd...

Embodiment 3

[0056] Prepare UV-curable polyurethane-based conductive silver paste according to the following formula:

[0057]

[0058] (1) Preparation of ultrafine spherical silver: 6.40gPVP, 0.05gCTAB and 1.76g ascorbic acid were dissolved in deionized water, and sodium hydroxide was added to adjust the pH to 12.0, and 50ml of reducing solution was prepared; 1.70gAgNO 3 Dissolved in deionized water and diluted to 1.0mol / L, AgNO at 200r / min 3 Add it dropwise to the reducing solution, control the dropping time to 30min, and the reaction temperature to 0°C. After the dropwise addition, continue to react for 60min; centrifuge the reacted suspension (high-speed desktop centrifuge: GT10-1, Beijing Times North Lee Centrifuge Co., Ltd.) at 8000r / min for 30min, and the centrifuged product was washed once with deionized water, absolute ethanol and acetone; the washed ultrafine spherical silver was dried at 30°C and 0.1mmHg for 48h to prepare ultrafine The fine spherical silver powder is ready ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com