Preparation method and application of a photosensitive resin for UV curing 3D printing

A photosensitive resin, 3D printing technology, applied in photosensitive materials for opto-mechanical equipment, opto-mechanical equipment, photo-engraving process of pattern surface, etc. Small size, improved curing and molding accuracy, and high manufacturing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

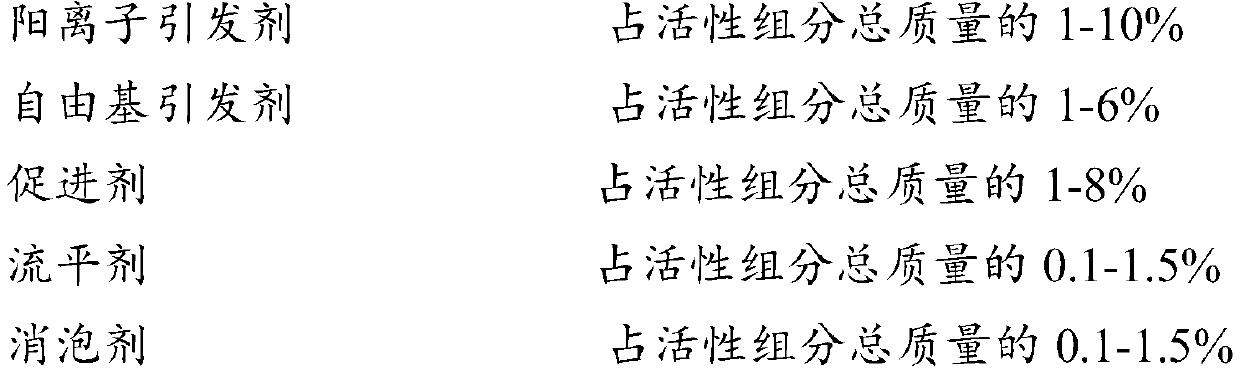

Method used

Image

Examples

Embodiment 1

[0047] In a 2000 ml four-necked glass bottle equipped with a condenser and a stirring device, add 616 grams of bis(3-ethyl-3-oxetanyl) methyl ether (OXT221, Japan Toya Synthetic Chemical Co., Ltd.), spiro ring Orthoester 184.8g, propoxylated trimethylolpropane triacrylate 431.2g, 1,4-cyclohexyldimethanol divinyl ether 168g, Irgacure 261 70g, benzoin dimethyl ether 42g, 3, 70 grams of 4-dimethoxybenzyl alcohol, 0.84 grams of octamethyltetrasiloxane polyethylene oxide copolymer, and 0.98 grams of GPE polyether / hydrophobic white carbon black composite defoamer.

[0048] Heat to a certain temperature and stir until it becomes a transparent light yellow uniform liquid, which is a prepared photosensitive resin. Using this photosensitive resin as material, some parts were made by using SPS250J laser rapid prototyping machine of Shaanxi Hengtong Intelligent Machine Co., Ltd.

[0049] After the prepared photosensitive resin is cured by ultraviolet light, its volume change and warpage ...

Embodiment 2

[0051] In a 2000 ml four-necked glass bottle equipped with a condenser and a stirring device, add 675 grams of bis(3-ethyl-3-oxetanyl) methyl ether (OXT221, Japan Toya Synthetic Chemical Co., Ltd.), spiro ring Ortho ester 202.5g, tripropylene glycol diacrylate 283.5g, trimethylolpropane triacrylate 189g, 1,4-cyclohexyldimethanol divinyl ether 150g, Irgacure 261 67.5g, benzoin dimethyl 45 grams of ether, 69 grams of 3,4-dimethoxybenzyl alcohol, 0.9 grams of polymethylphenylpolyethylene oxide copolymer, 1.05 grams of GPE polyether / hydrophobic silica composite defoamer.

[0052] Heat to a certain temperature and stir until it becomes a transparent light yellow uniform liquid, which is a prepared photosensitive resin. Using this photosensitive resin as material, some parts were made by using SPS250J laser rapid prototyping machine of Shaanxi Hengtong Intelligent Machine Co., Ltd.

[0053] After the prepared photosensitive resin is cured by ultraviolet light, the measured volume s...

Embodiment 3

[0055] In a 2000 ml four-neck glass bottle equipped with a condenser and a stirring device, add 620 grams of bis(3-ethyl-3-oxetanyl) methyl ether (OXT221, Japan Toya Synthetic Chemical Co., Ltd.), spiro ring Orthocarbonate 186g, Propoxylated Trimethylolpropane Triacrylate 434g, Triethylene Glycol Divinyl Ether 186g, Irgacure 261 74.4g, Benzoin Dimethyl Ether 49.6g, 3,4-Methylene Dioxygen 74.4 grams of benzyl alcohol, 0.93 grams of polymethylphenylpolyethylene oxide copolymer, and 1.08 grams of GP polyether / hydrophobic silica composite defoamer. Heat to a certain temperature and stir until it becomes a transparent light yellow uniform liquid, which is a prepared photosensitive resin. Using this photosensitive resin as material, some parts were made by using SPS250J laser rapid prototyping machine of Shaanxi Hengtong Intelligent Machine Co., Ltd.

[0056] After the prepared photosensitive resin is cured by ultraviolet light, the volume shrinkage rate Χ=0.5% is measured; the war...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com