A Deformation Monitoring Method for Construction of Shallow Buried Underground Tunnel

A technology for shallow buried excavation and tunnel construction, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., to meet the needs of surface subsidence monitoring, with simple method steps and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Such as figure 1 A deformation monitoring method for the construction of a shallow-buried tunnel is shown, comprising the following steps:

[0058] Step 1. Tunnel excavation construction: Excavate the tunnel hole of the shallow buried tunnel under construction from the back to the front. Describe the primary support structure of the tunnel hole.

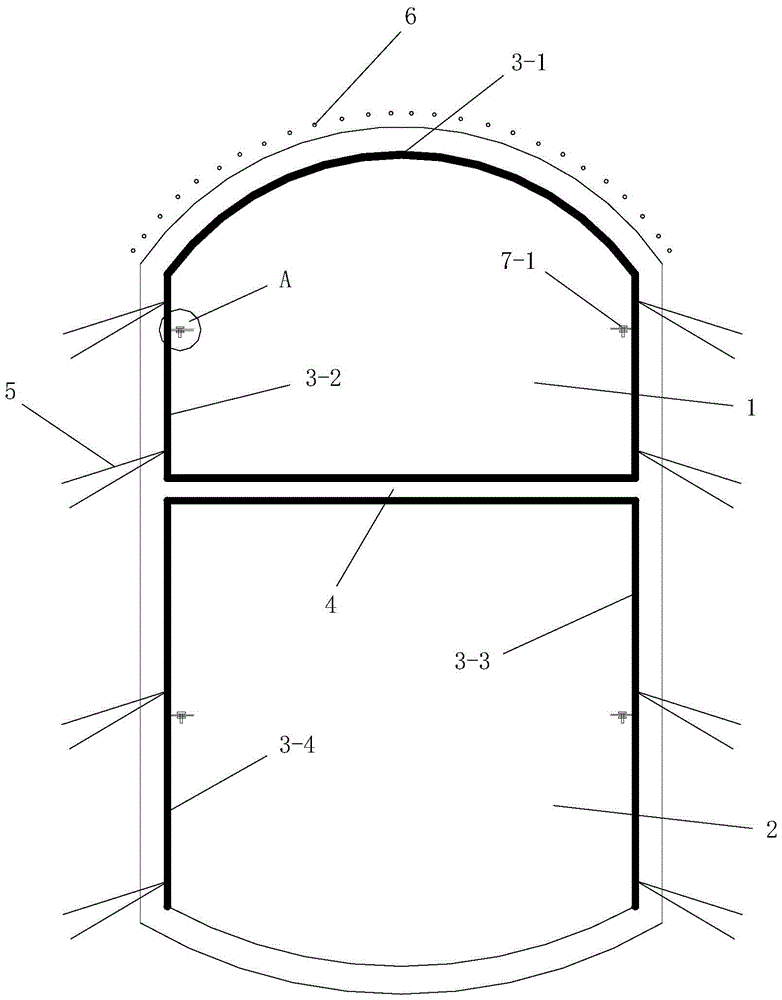

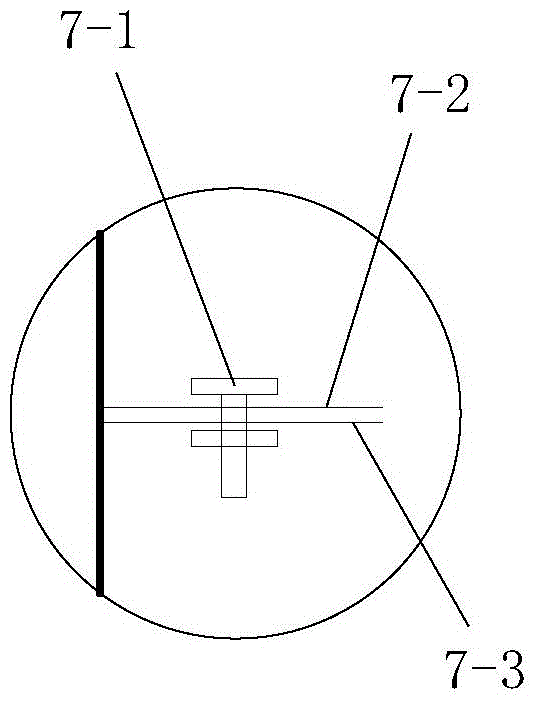

[0059] combine figure 2 The initial support structure of the tunnel hole includes multiple grid steel frames supporting the tunnel hole from the back to the front, and the grid steel frame is hung on the inner wall of the tunnel hole after the support is completed. A layer of reinforcement mesh and the reinforcement mesh are hung and dug into the concrete layer sprayed on the inner wall of the tunnel hole, and the grid steel frame and the reinforcement mesh are fixed in the concrete layer; The structures of the grid steel frames are all the same, and they are arranged from back to front along the longitudinal extension dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com