Halogen-free flame-retardant finishing agent and preparation method thereof

A kind of flame retardant finishing agent and pretreatment technology, which can be used in fiber processing, textile and paper making, etc., can solve problems such as the inability to meet market demands, and achieve the effect of high flame retardant grade and improvement of flame retardant grade.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

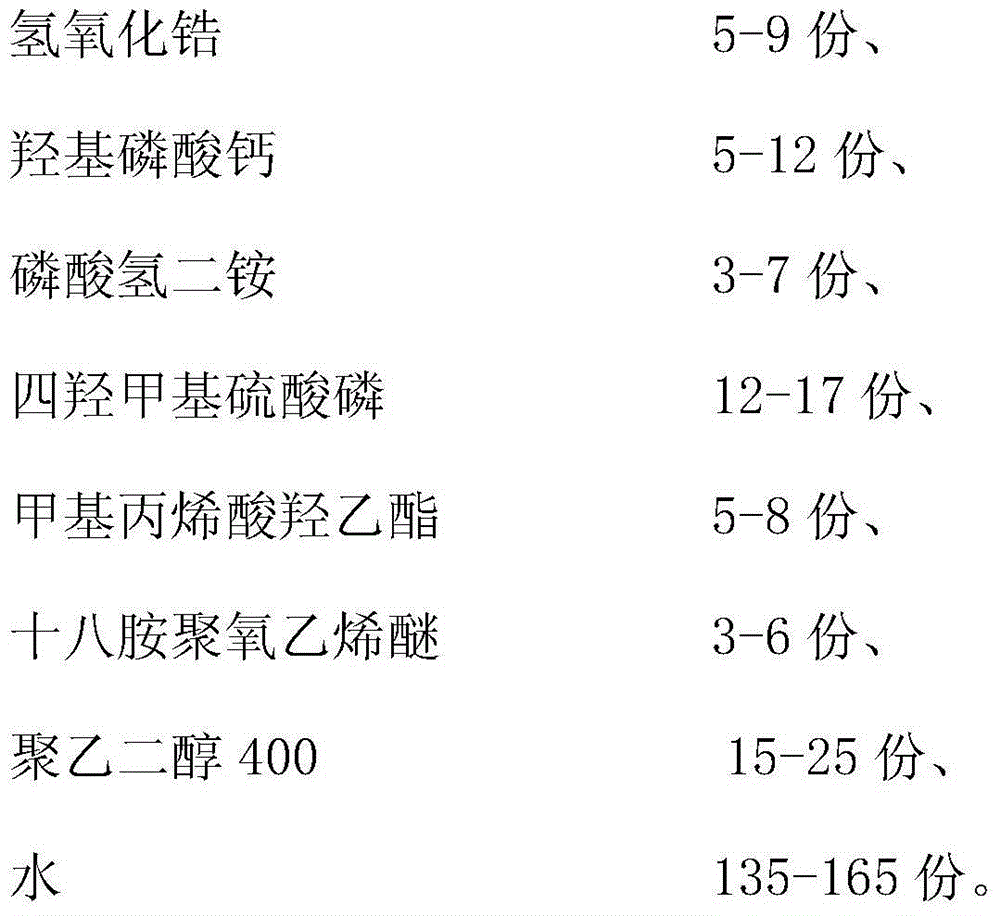

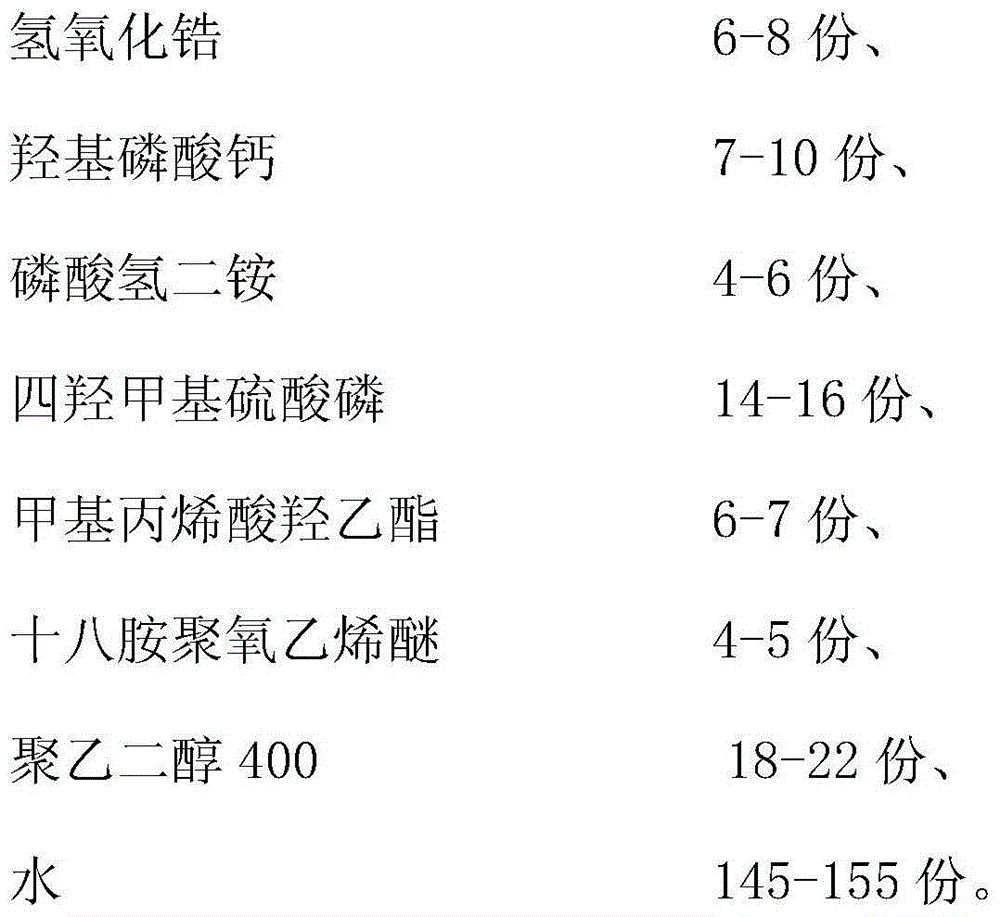

Method used

Image

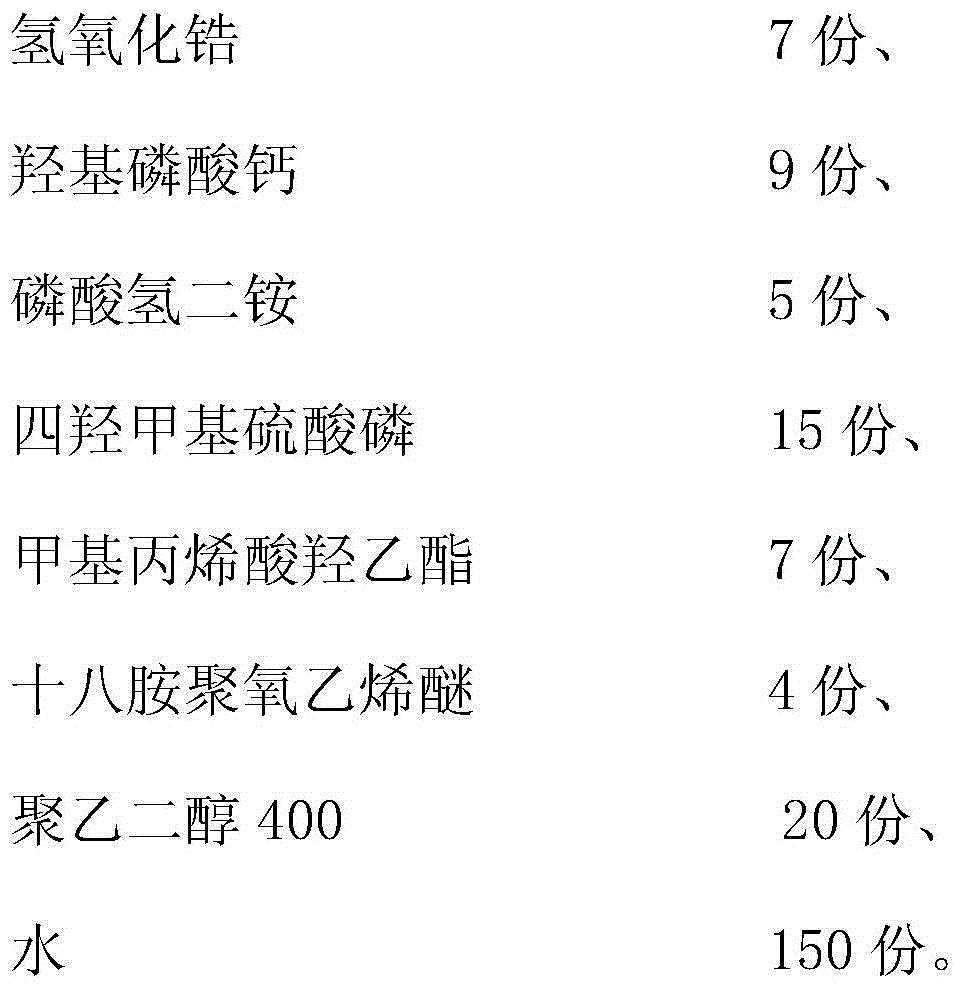

Examples

Embodiment 1

[0017] (1) Raw material pretreatment: take zirconium hydroxide, calcium hydroxyphosphate, and diammonium hydrogen phosphate, and mechanically pulverize the three materials of zirconium hydroxide, calcium hydroxyphosphate, and diammonium hydrogen phosphate with a pulverizer, and pulverize them into the above three components Both are 400 mesh;

[0018] (2) 9 parts of zirconium hydroxide, 12 parts of calcium hydroxyphosphate, 3 parts of diammonium hydrogen phosphate, 17 parts of tetrakis hydroxymethyl phosphorus sulfate, 8 parts of hydroxyethyl methacrylate, 3 parts of octadecylamine polyoxyethylene ether, 25 parts of polyethylene glycol 400, and 165 parts of water. Put the above-mentioned various components into water and stir them. After stirring for 30 minutes, store them. This is the prepared halogen-free flame-retardant finishing agent.

Embodiment 2

[0020] (1) Raw material pretreatment: take zirconium hydroxide, calcium hydroxyphosphate, and diammonium hydrogen phosphate, and mechanically pulverize the three materials of zirconium hydroxide, calcium hydroxyphosphate, and diammonium hydrogen phosphate with a pulverizer, and pulverize them into the above three components Both are 200 mesh;

[0021] (2) 5 parts of zirconium hydroxide, 5 parts of calcium hydroxyphosphate, 7 parts of diammonium hydrogen phosphate, 12 parts of tetrakis hydroxymethyl phosphorous sulfate, 5 parts of hydroxyethyl methacrylate, 6 parts of octadecylamine polyoxyethylene ether, 15 parts of polyethylene glycol 400, and 135 parts of water. Put the above-mentioned various components into water and stir, and store after stirring for 30 minutes. This is the prepared halogen-free flame-retardant finishing agent.

Embodiment 3

[0023] (1) Raw material pretreatment: take zirconium hydroxide, calcium hydroxyphosphate, and diammonium hydrogen phosphate, and mechanically pulverize the three materials of zirconium hydroxide, calcium hydroxyphosphate, and diammonium hydrogen phosphate with a pulverizer, and pulverize them into the above three components Both are 400 mesh;

[0024] (2) 6 parts of zirconium hydroxide, 10 parts of calcium hydroxyphosphate, 4 parts of diammonium hydrogen phosphate, 16 parts of tetrakis hydroxymethyl phosphorus sulfate, 7 parts of hydroxyethyl methacrylate, 5 parts of octadecylamine polyoxyethylene ether, 18 parts of polyethylene glycol 400, and 145 parts of water. Put the above-mentioned various components into water and stir them. After stirring for 30 minutes, store them. This is the prepared halogen-free flame-retardant finishing agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com