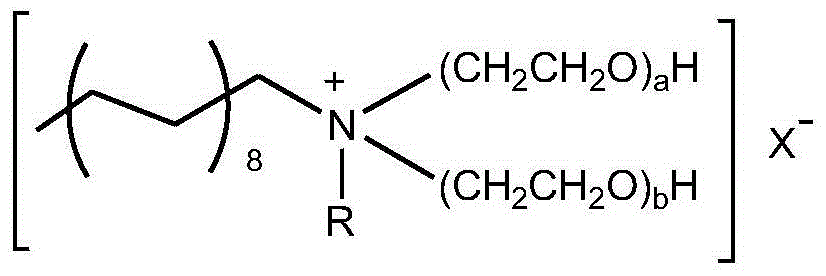

Method for extracting removal of sulfides from fuel oil by using polyether type octadecylamine ionic liquid

A polyether-type octadecylamine and ionic liquid technology, which is applied in the treatment of hydrocarbon oil, petroleum industry, refined hydrocarbon oil, etc., can solve the problems of complex synthesis steps, expensive cost of ionic liquid, low recycling rate, etc., and achieve simple operation , simple equipment requirements, high desulfurization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

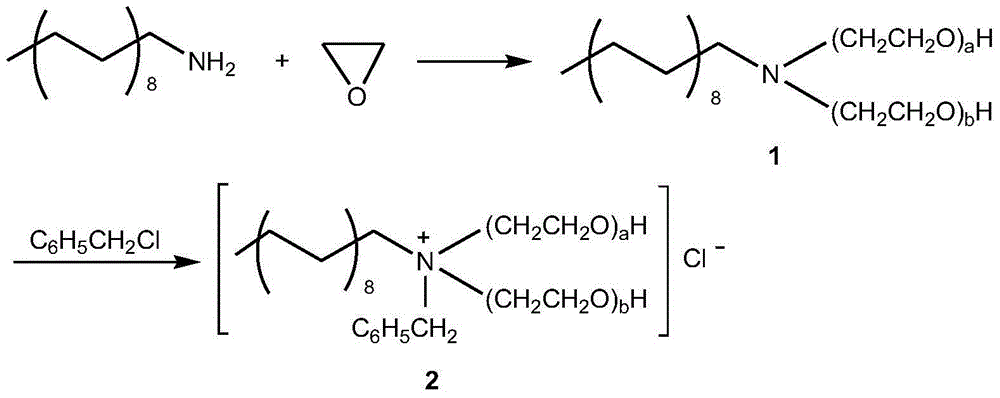

Embodiment 1

[0019] Example 1: 2.6951 g of octadecylamine and 10 mL of absolute ethanol were added into a high-pressure reactor, and placed in a refrigerator to freeze overnight. Then add 30mL ethylene oxide, seal, and use 5MPa N 2 Replace the air in the kettle 3 to 5 times. Stir at room temperature for 2 hours, then insulate and react at 70°C for 8 hours, lower the temperature, release the pressure, open the kettle, and transfer the reaction mixture into a three-neck flask. The absolute ethanol was removed by distillation under reduced pressure to constant weight to obtain intermediate 1, and the average degree of polymerization (n) of intermediate 1 could be calculated according to the product weight gain method. Add intermediate 1 and benzyl chloride of the amount of the same substance in the reaction kettle, and use N 2 Replace the air in the kettle 3 to 5 times, blow in N 2 To 5MPa, react at 90°C for 10h. Lower the temperature, release the pressure, open the kettle, move the react...

Embodiment 2

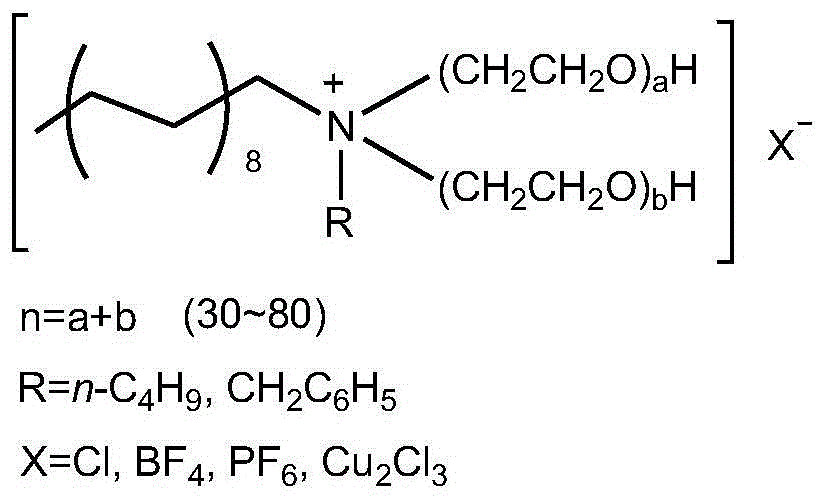

[0022] Embodiment 2: Accurately weigh 3.00g ionic liquid (X=Cl, R=CH 2 C 6 h 5 , n=60) and 2.00 g of simulated oil (dibenzothiophene, with a sulfur content of 500 ppm) were placed in a 50 mL round-bottomed flask, quantitative aids and a rotor were added, and the reaction was stirred and reacted in a water bath at 40° C. for 5 min. The desulfurization rate is 79.1%.

Embodiment 3

[0023] Embodiment 3: Accurately weigh 3.00g ionic liquid (X=Cl, R=CH 2 C 6 h 5 , n=30) and 2.00 g of simulated oil (dibenzothiophene, with a sulfur content of 500 ppm) were placed in a 50 mL round-bottomed flask, quantitative aids and a rotor were added, and the reaction was stirred in a water bath at 40°C for 5 min. The desulfurization rate is 72.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com