Modified alkadiene polymer as well as preparation method and application thereof

A technology of diene polymer and conjugated diene, which is applied in the application field of modified diene polymer as rubber base rubber, can solve the problems such as the inability to effectively improve the wet skid resistance and rolling resistance of rubber.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

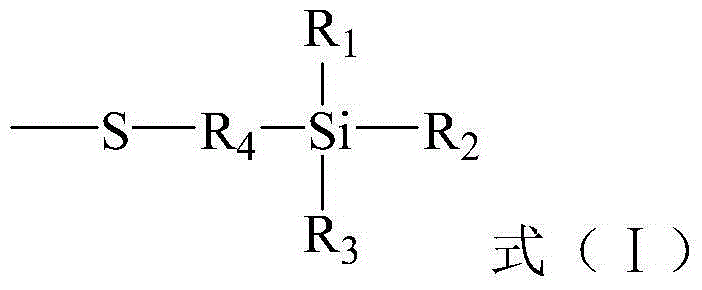

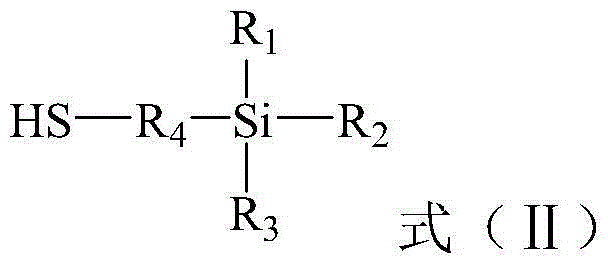

[0037] The preparation method of the modified diene polymer provided by the invention comprises in an inert atmosphere and in the presence of an initiator, the diene polymer containing a monovinylarene structural unit and a conjugated diene structural unit is coupled with a silane agent contact, the conditions of the contact make the silane coupling agent chemically bonded to the diene polymer; the number average molecular weight of the diene polymer is 50,000-1 million, and the diene polymer Based on the weight of the conjugated diene structural unit in the product, the content of the conjugated diene structural unit with double bonds in the side chain in the diene polymer is 15-85% by weight, preferably 30-60% by weight, and the The silane coupling agent has the structure shown in formula (II):

[0038]

[0039] Among them, R 1 -R 4 for C 1 -C 20 straight-chain or branched-chain hydrocarbon groups or C containing heteroatoms 1 -C 20 A linear or branched hydrocarbon ...

Embodiment 1

[0072] This example is used to illustrate the modified diene polymer provided by the present invention and its preparation method.

[0073] (1) In a 5-liter stainless steel stirred tank, under the protection of high-purity nitrogen, add 2288g cyclohexane, 31.2g styrene, 112.3g butadiene and 1.1g tetrahydrofurfuryl alcohol ethyl ether, then add 1.1 mmol of n-butyllithium and the pressure was controlled at 0.2 MPa to initiate a reaction for 2 hours to obtain a solution containing a diene polymer. The number average molecular weight of the diene polymer is 182,000, and based on the weight of the conjugated diene structural unit in the diene polymer, the conjugated diene in the diene polymer contains double bonds The content of the structural unit was 43.02% by weight, the content of the styrene structural unit was 21.74% by weight, and the content of the butadiene structural unit was 78.26% by weight.

[0074] (2) Add 0.8ml (0.836g) of γ-mercaptopropyltrimethoxysilane to the pro...

Embodiment 2

[0076] This example is used to illustrate the modified diene polymer provided by the present invention and its preparation method.

[0077] (1) In a 5-liter stainless steel stirred tank, under the protection of high-purity nitrogen, add 2288g cyclohexane, 31.2g vinyl toluene, 112.32g isoprene and 0.65g tetrahydrofuran, then add 1.0mmol after heating to 45°C n-butyllithium and the pressure was controlled at 0.1MPa to initiate the reaction for 2 hours to obtain a solution containing a diene polymer, then add 0.06mmol of tin tetrachloride and react at 60°C for 30min to obtain a coupling efficiency of 27% polymer. The number average molecular weight of the diene polymer is 194,000, and based on the weight of the conjugated diene structural unit in the diene polymer, the conjugated diene in the diene polymer contains double bonds The content of the structural unit was 33.03% by weight, the content of the vinyltoluene structural unit was 21.74% by weight, and the content of the iso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com