A kind of method for continuously preparing 2,3,5-trimethylbenzoquinone

A technology for refining trimethylbenzoquinone and oil phase, which is applied in the preparation of oxidized quinone, separation/purification of quinone, organic chemistry, etc. It can solve problems that are not suitable for industrial applications, achieve good heat and mass transfer characteristics, and improve utilization rate , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

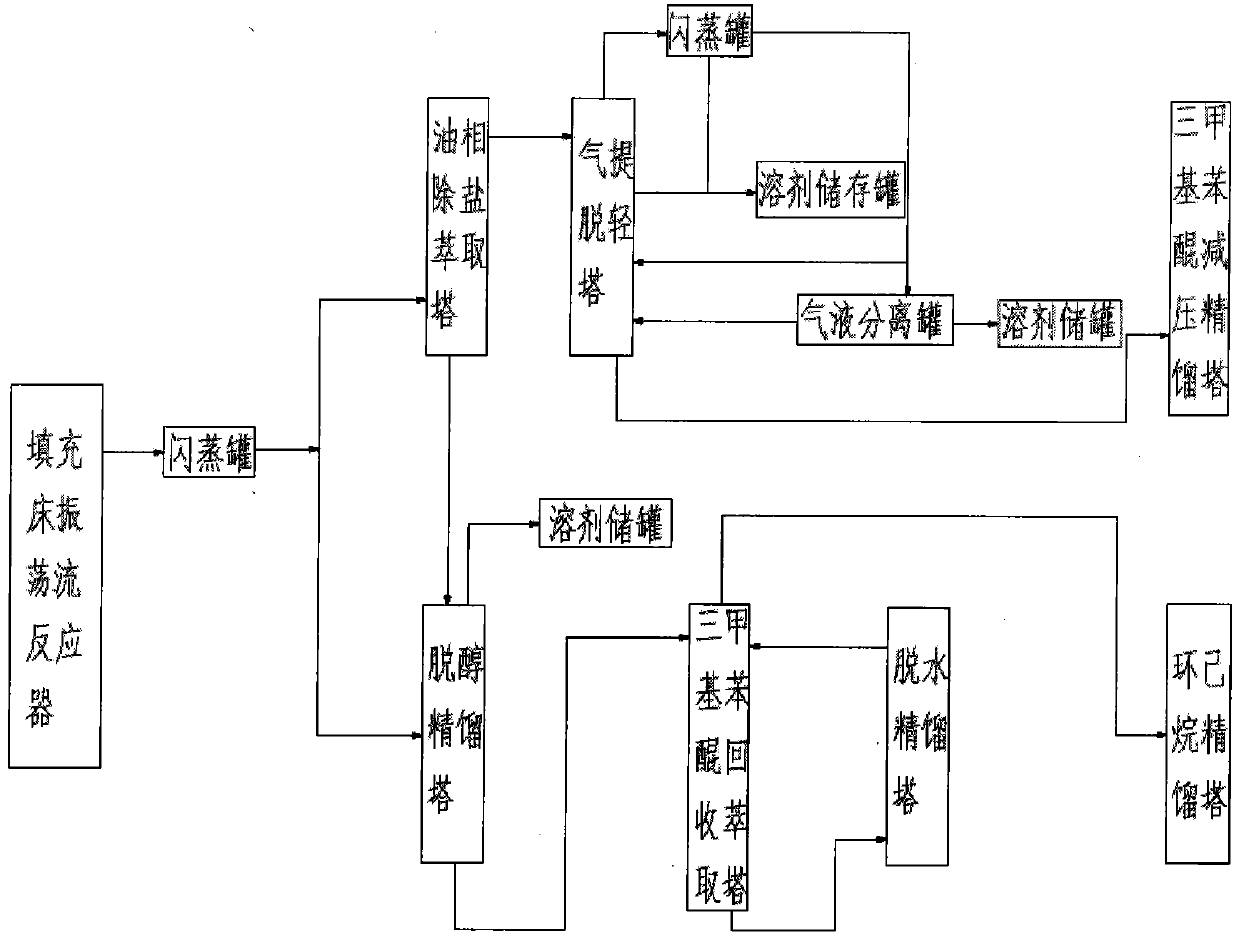

[0024] A method for continuously preparing 2,3,5-trimethylbenzoquinone, such as figure 1 As shown, it specifically includes the following steps:

[0025] 1) In the reaction process, the reaction raw material 2,3,6-trimethylphenol is dissolved in a mixed solvent composed of an organic solvent and water, the composite catalyst copper chloride and lithium chloride are dissolved in water, and the oxidizing agent is industrial pure oxygen, which enters Oxidation reaction takes place in the packed bed oscillating flow reactor, the reaction temperature is controlled at 40-80°C, the pressure is controlled at 0.1-1.0MPa (absolute pressure), and the simultaneous production of 2,3,5-trimethylbenzoquinone and organic solvents is obtained. The oil phase containing a small amount of catalyst and water, and the water phase mainly containing water and catalyst and containing a small amount of organic solvent and 2,3,5-trimethylbenzoquinone, enter the oil phase refining process and water phase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com