Piezoelectric material

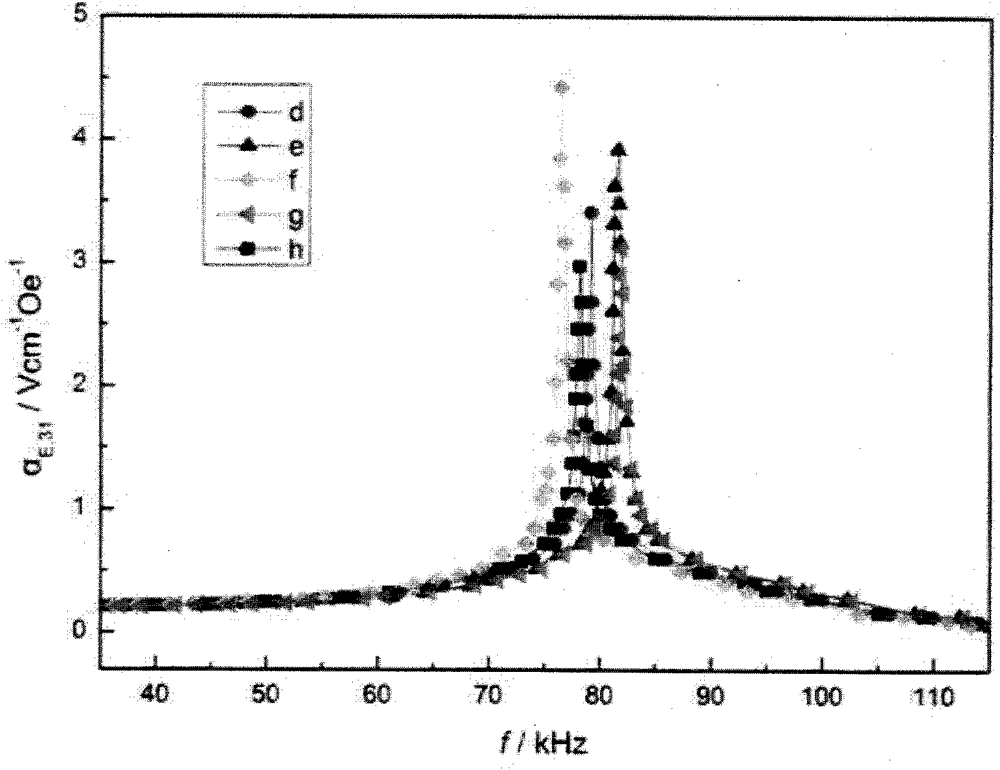

A technology of piezoelectric materials and magnetoelectric composite materials, applied in the field of barium titanate piezoelectric materials and piezoelectric materials, can solve the problems of low magnetoelectric effect, harm to human body and environment, etc., and achieve strong magnetoelectric effect , strong resonant magnetoelectric effect, and the effect of improving the magnetoelectric voltage coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Piezoelectric material preparation:

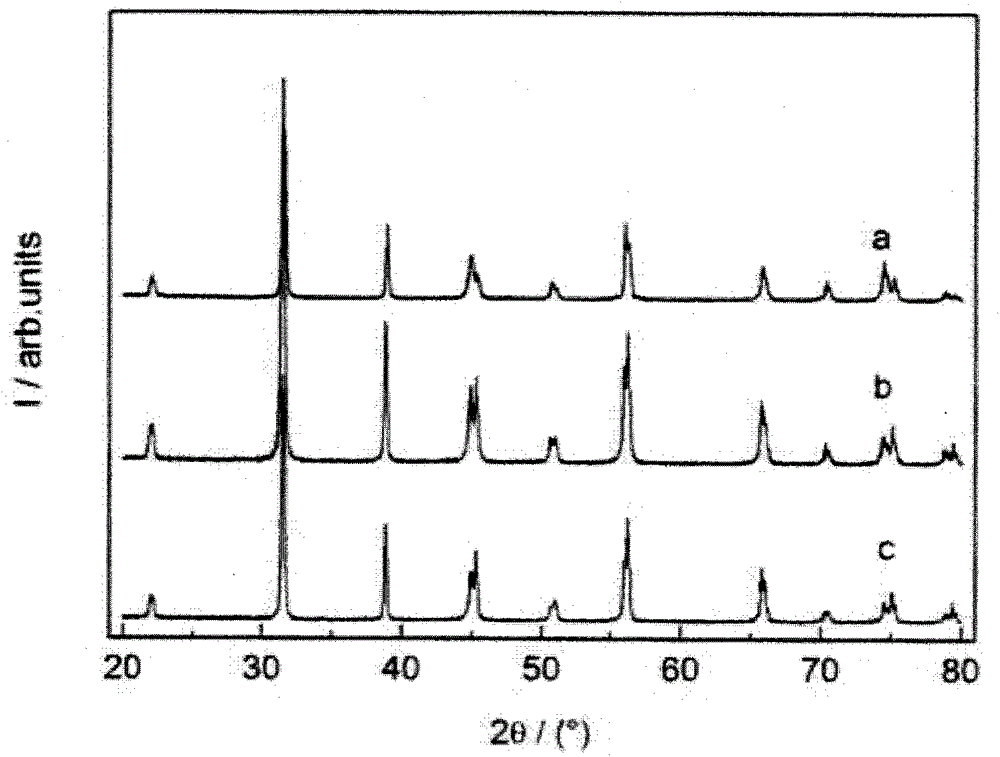

[0022] 1. Preparation of precursor powder by sol-gel method: preparation of 0.5% mol chromium (Cr) doped barium titanate (BaTiO 3 ) precursor powder. The raw material used is barium carbonate (BaCO 3 ), titanium dioxide (TiO 2 ), chromium trioxide (Cr 2 o 3 ) and citric acid CIT (C 6 h 8 o 7 .H 2 O). The molar ratio of barium carbonate, titanium dioxide, chromium trioxide and citric acid is 1:0.995:0.0025:3.2. After fully stirring the raw materials in distilled water, place them on a heating magnetic stirrer, heat and stir for several hours, until the solution in the beaker becomes a uniformly fused translucent liquid. Place the beaker in a drying oven and dry it for several hours until the water is completely evaporated into a solid state. The solid material was ground into fine powder, and placed in a muffle furnace for pre-sintering at 400° C. for 6 hours to obtain the desired precursor powder of 0.5% moICr-doped bariu...

Embodiment 2

[0028] Piezoelectric material preparation:

[0029] 1. Preparation of precursor powder by sol-gel method: the raw material used is barium carbonate (BaCO 3 ), titanium dioxide (TiO 2 ), chromium trioxide (Cr 2 o 3 ) and citric acid CIT (C 6 h 8 o 7 .H 2 O). The molar ratio of barium carbonate, titanium dioxide, chromium trioxide and citric acid is 1:0.99:0.005:3.2. After fully stirring the raw materials in distilled water, place them on a heating magnetic stirrer, heat and stir for several hours, until the meat solution in the beaker becomes a uniformly fused translucent liquid. Place the beaker in a drying oven and dry it for several hours until the water is completely evaporated into a solid state. The solid material was ground into fine powder, and placed in a muffle furnace for pre-sintering at 450° C. for 6.5 hours to obtain the desired precursor powder of 1.0% moICr-doped barium titanate.

[0030]2. Tablet pressing and sintering: Press the powder on a tablet pr...

Embodiment 3

[0035] Piezoelectric material preparation:

[0036] 1. Preparation of precursor powder by sol-gel method: the raw material used is barium carbonate (BaCO 3 ), titanium dichloride (TiO 2 ) and chromium trioxide (Cr 2 o 3 ) and complexing agent citric acid CIT (C 6 h 8 o 7 .H 2 O). The molar ratio of barium carbonate, titanium dioxide, chromium trioxide and citric acid is 1:0.985:0.0075:3. After fully stirring the raw materials in distilled water, place them on a heating magnetic stirrer, heat and stir for several hours, until the solution in the beaker becomes a uniformly fused translucent liquid. Place the beaker in a drying oven and dry it for several hours until the water is completely evaporated into a solid state. The solid material was ground into fine powder, and placed in a muffle furnace for pre-sintering at 400° C. for 6 hours to obtain the desired precursor powder of 1.5% moICr-doped barium titanate.

[0037] 2. Tablet pressing and sintering: Press the powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetostriction | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com