Preparation method of transparent tetravalent chromium-doped yttrium aluminum garnet ceramics

A technology of yttrium aluminum garnet and transparent ceramics, which is applied in the preparation of tetravalent chromium-doped yttrium aluminum garnet transparent ceramics, and in the field of Cr4+:YAG transparent ceramics, which can solve the problem of inability to use laser output or Q-switching, and the conversion rate of tetravalent chromium Low, low transmittance and other problems, to achieve the effect of reasonable grain distribution, high density and high transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Composition as in Table 1 1 # Shown, specific preparation method comprises the following steps:

[0031] ① Weigh the raw materials according to the composition in Table 1. First, put the oxide raw material powder into a high-purity alumina ball mill tank, add sintering aids, charge balance agents, and absolute ethanol to prepare the slurry; ball mill on a planetary ball mill Mix for 10 hours, and the rotating speed is 160r / min to obtain the prepared Cr 4+ : Slurry used for YAG transparent ceramics;

[0032] ② The slurry obtained in step ① was dried in an oven at 55°C and sieved, and then the obtained powder was pressed into discs by dry pressing at 60 MPa with a mold, and then subjected to cold isostatic pressing at 200 MPa to obtain a biscuit.

[0033] ③Put the biscuit obtained in step ② in the air at 920°C for 8 hours, then vacuum sinter at 1780°C for 8 hours, and finally anneal in air at 1500°C for 15 hours to obtain dense Cr 4+ : YAG transparent ceramics, after g...

Embodiment 2

[0035] Composition as in Table 1 2 # Shown, specific preparation method comprises the following steps:

[0036] ①Weigh the raw materials according to the composition in Table 1. First, put the oxide raw material powder into a high-purity alumina ball mill tank, and add sintering aids, charge balance agents, and absolute ethanol to prepare the slurry; Ball milling was mixed for 18 hours, and the rotating speed was 120r / min to obtain the prepared Cr 4+ : Slurry used for YAG transparent ceramics;

[0037] ②The slurry obtained in step ① was dried, sieved, and dry pressed according to the process parameters of step ② in Example 1, and then cold isostatic pressed at 150Mpa to obtain a green body.

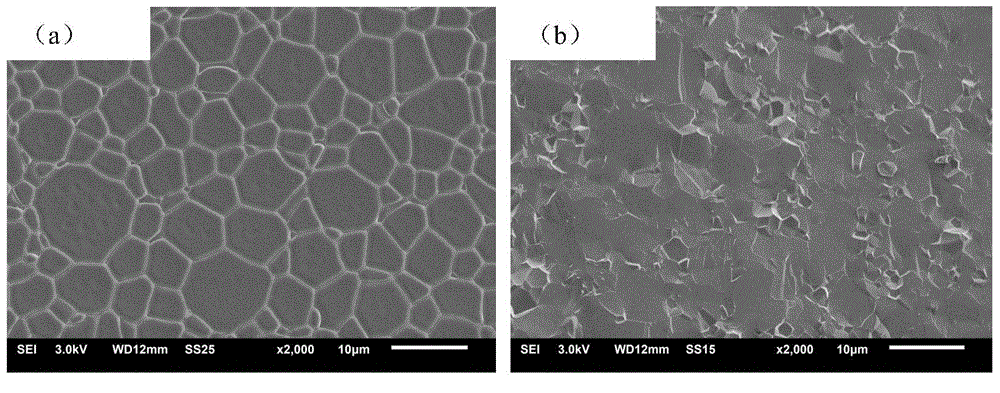

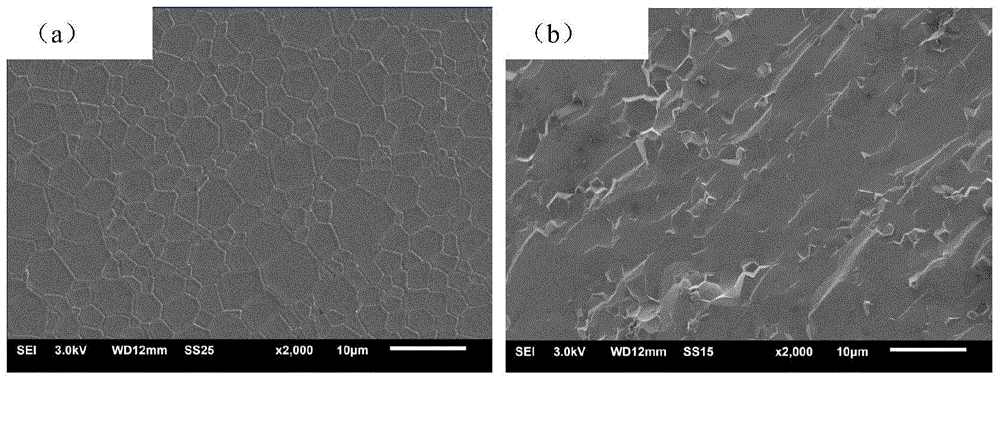

[0038] ④Put the biscuit obtained in step ② in the air at 800°C for 10h, then vacuum sinter at 1730°C for 30h, and finally anneal in air at 1300°C for 25h to obtain dense Cr 4+ : YAG transparent ceramics, after grinding and polishing, the polished surface and cross-section SEM images of...

Embodiment 3

[0040] Composition as in Table 1 3 # Shown, specific preparation method comprises the following steps:

[0041] ① Weigh the raw materials according to the composition in Table 1. First, put the oxide raw material powder into a high-purity alumina ball mill tank, add sintering aids, charge balance agents, and absolute ethanol to prepare the slurry; ball mill on a planetary ball mill Mix for 8 hours, and the rotating speed is 300r / min to obtain the prepared Cr 4+ : Slurry used for YAG transparent ceramics;

[0042] ② The slurry obtained in step ① is dried, sieved, and dry pressed according to the process parameters of step ② in Example 1, and then cold isostatic pressed at 250Mpa to obtain a green body.

[0043] ④Put the biscuit obtained in step ② in the air at 1000°C for 5 hours, then place it in vacuum sintering at 1850°C for 4 hours, and finally anneal in the air at 1550°C for 10 hours to obtain dense Cr 4+ : YAG transparent ceramics, after grinding and polishing, the poli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com