A kind of oil sludge demulsifier and oil sludge treatment process

A demulsifier and oil sludge technology, which is used in dewatering/drying/concentrating sludge treatment, hydrocarbon oil treatment, and petroleum industry, etc. Good effect, excellent demulsification and dispersing performance, excellent effect of biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

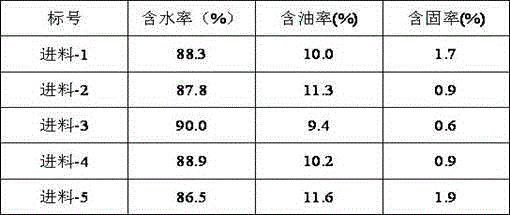

Examples

Embodiment 1

[0031] Fatty acid methyl ester ethoxylate (R=C 18 , n=7) 28 parts, lauryl amidopropyl hydroxysultaine (R=C 12 ), 2 parts of sodium gluconate, and 69 parts of water were mixed in a reaction kettle at a temperature of 55°C for 40 minutes to obtain a sludge demulsifier.

Embodiment 2

[0033] Fatty acid methyl ester ethoxylate (R=C 16 , n=7) 10 parts, lauryl amidopropyl hydroxysultaine (R=C 12 ), 5 parts of sodium oleate, and 84 parts of water were mixed in a reaction kettle at a temperature of 55°C for 35 minutes to obtain a sludge demulsifier.

Embodiment 3

[0035] Fatty acid methyl ester ethoxylate (R=C 18 , n=7) 14 parts, lauryl amidopropyl hydroxysultaine (R=C 12 ), 7 parts of sodium oleate, and 78 parts of water were mixed in a reaction kettle at a temperature of 52°C for 35 minutes to obtain a sludge demulsifier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com