Synthetic method for small-crystal-size high-silicon Y-type molecular sieve

A synthesis method and small crystal grain technology, applied in the direction of crystalline aluminosilicate zeolite, octahedral crystalline aluminosilicate zeolite, etc., can solve the problems of low external area, easy coking, unfavorable material diffusion, etc., and achieve industrial production. The effect of low synthesis cost and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

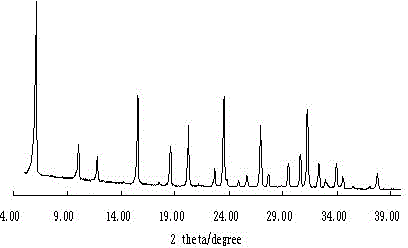

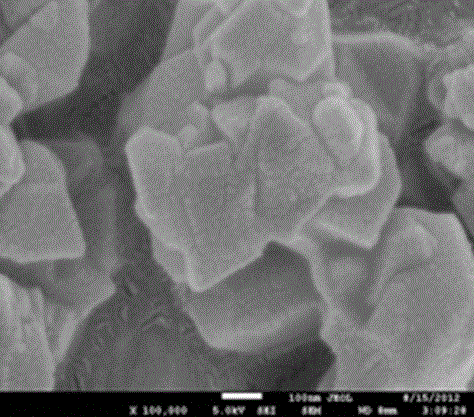

Image

Examples

Embodiment 1

[0040] (1) First mix 40mL of distilled water with 6g of sodium hydroxide, add 1.5g of sodium aluminate after dissolution, add 8g of white carbon black after the dissolution is complete, and then place it in a water bath at 40°C and stir for 72 hours.

[0041] (2) Slowly add 10 mL of 3.75 mol / L hydrochloric acid dropwise to the mixture obtained in step (1). During the dropwise addition, the mixture should be prevented from undergoing morphological transformation due to drastic local pH changes.

[0042] (3) Mix and add 6g of white carbon black to the mixture obtained in step (2), then stir at room temperature for 1h, then put the reaction mixture into the reactor, seal the reactor, and place the reactor in an oven at 100°C Crystallize for 50 hours, and finally dry the solid product at 120°C for 12 hours. The obtained sample number is CL1, which is a pure Y-type molecular sieve with a silicon-aluminum ratio of 5.9 and a particle size of 210nm.

Embodiment 2

[0044] (1) First mix 40mL of distilled water with 6g of sodium hydroxide, add 9g of aluminum nitrate after dissolution, add 8g of white carbon black after the dissolution is complete, then place in a 35°C water bath and stir for 72h.

[0045] (2) Slowly add 9 mL of 3.75 mol / L hydrochloric acid dropwise to the mixture obtained in step (1). During the dropwise addition, the mixture should be prevented from undergoing morphological transformation due to severe local pH changes.

[0046] (3) Mix and add 6g of white carbon black to the mixture obtained in step (2), then stir at room temperature for 1h, then put the reaction mixture into the reactor, seal the reactor, and place the reactor in an oven at 100°C The crystallization was carried out for 55 hours, and finally the solid product was dried at 120°C for 12 hours. The obtained sample number was CL2, which was a small-grain high-silicon Y-type molecular sieve.

Embodiment 3

[0048] (1) First mix 45mL of distilled water with 5.5g of sodium hydroxide, add 7g of aluminum nitrate after dissolution, add 8g of white carbon black after the dissolution is complete, then place in a 45°C water bath and stir for 60h.

[0049] (2) Slowly add 10 mL of 3.75 mol / L hydrochloric acid dropwise to the mixture obtained in step (1). During the dropwise addition, the mixture should be prevented from undergoing morphological transformation due to drastic local pH changes.

[0050] (3) Mix and add 5g of white carbon black to the mixture obtained in step (2), then stir at room temperature for 1.5h, then put the reaction mixture into the reactor, close the reactor, place the reactor in an oven at 110 It was crystallized at ℃ for 39 hours, and finally the solid product was dried at 120℃ for 12 hours. The obtained sample number is CL3, which is a small-grain high-silicon Y-type molecular sieve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com