Manufacturing method of environment-friendly high-strength anti-deformation solid wood composite door

A manufacturing method and composite door technology, which is applied in the jointing of wooden veneers, manufacturing tools, wood processing appliances, etc., can solve the problems of increasing raw material costs, finding customer resources, and wasting wood resources, so as to prevent cracking, The effect of saving forest resources and protecting the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for manufacturing a green, environment-friendly, high-strength, deformation-resistant solid wood composite door, comprising the following steps:

[0044] The first step is to soften the logs first, and then miniaturize them to make veneers;

[0045] In the second step, the veneer is divided into super-grade and first-grade panels, and second-grade and third-grade core materials, and then the selected grades of veneer are dried;

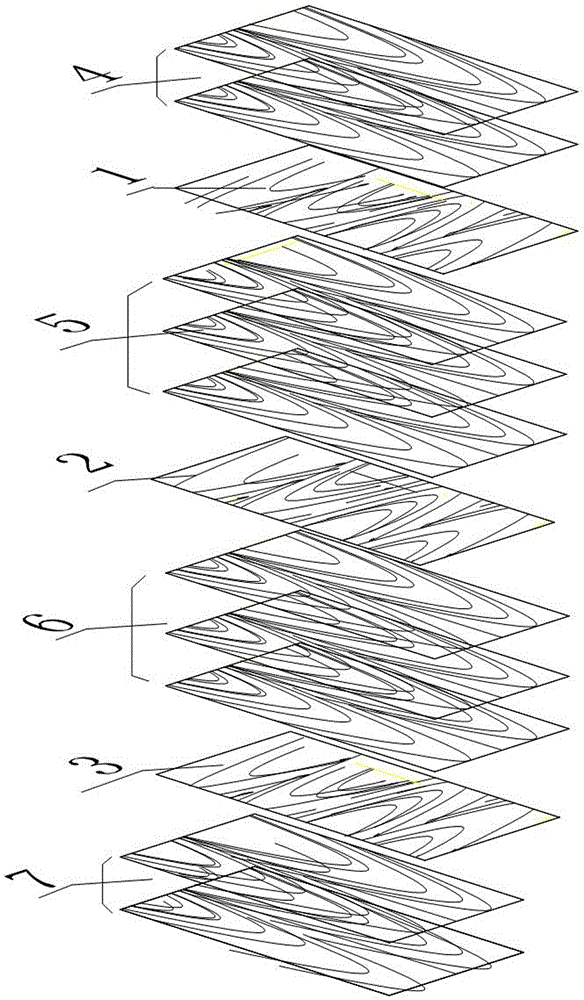

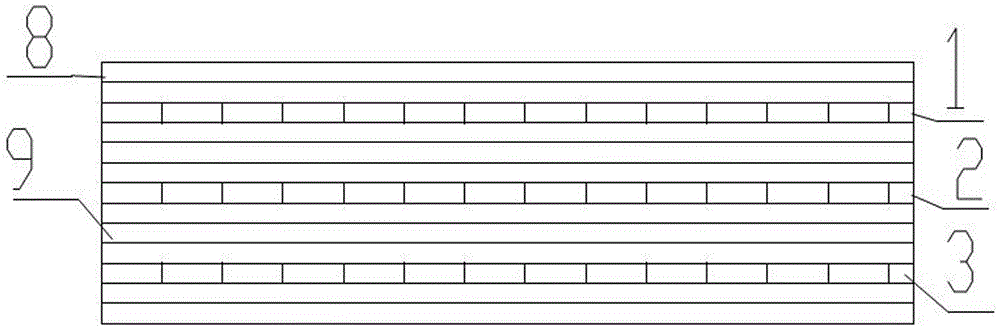

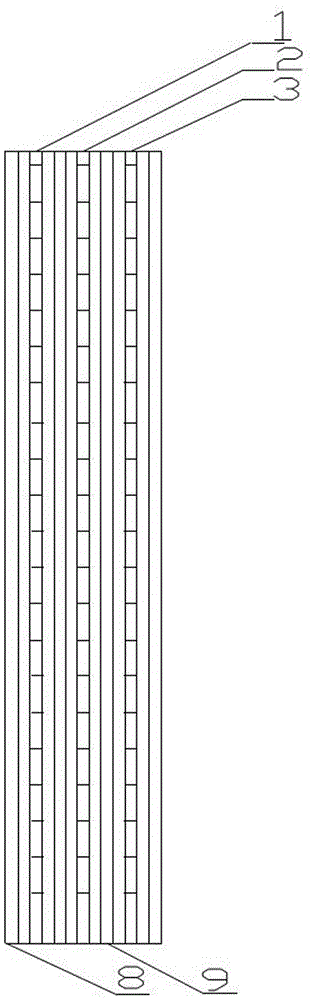

[0046] The third step is to trim the edges of the veneer boards and splice them into a whole board with a patchwork machine, then grade the whole board again, separate the face plate and core material, and then select the whole board with transverse grain from the core material as a balance The tension board and the balanced tension board are respectively placed in the center layer, the third layer of the upper surface layer, and the third layer of the lower surface layer, and the remaining layers are thin wood boards with long...

Embodiment 2

[0051] The manufacturing method of the green and environment-friendly high-strength anti-deformation solid wood composite door, the first step is to soften the logs first, which is to cook and soften the logs. Soak in water at 25-35°C for 6-10 hours, then steam the water with steam at 1.5 to 3 atmospheres; carry out miniaturization treatment to make thin wood boards. Clamp on the planer or rotary cutter, adjust the speed, adjust the thickness to 2mm, and cut the log into 1.8-2mm thin boards.

Embodiment 3

[0053] In the method for making the green and environment-friendly high-strength anti-deformation solid wood composite door, the second step is to classify the veneers, select super-grade veneers and first-grade veneers as panels, and select second-grade veneers and third-grade veneers as panels. core material, and then the veneer of the selected grade is dried by a hot-press drying method; After warming and pressing, the pressure is adjusted to 1mpa, the temperature is adjusted to be within 100°C, the pressure is reset to zero after 30-60 seconds of pressing, and the moisture content of the veneer can be kept within 6-12% after repeated several times.

[0054] In the manufacturing method of the green and environment-friendly high-strength anti-deformation solid wood composite door, the second step is to make the core material by sawing the assembled slabs into fixed-width and fixed-length sapwood along the grain direction as the long direction of the sapwood. Take the ass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com