Hydrogen plasma deoxidation method of chromium powder

A technology of hydrogen plasma and chromium powder, which is applied in the field of ion deoxidation, can solve the problems of long time, high ionization energy of hydrogen gas, and low efficiency, and achieve the effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

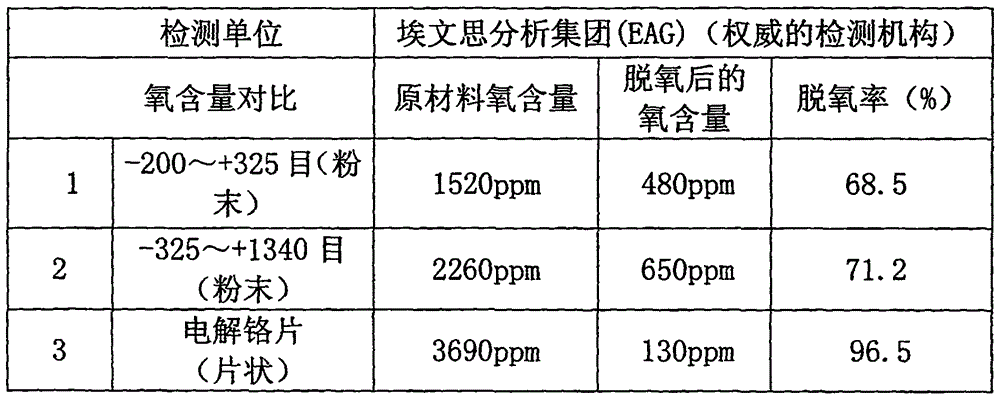

Examples

Embodiment 1

[0026] A hydrogen plasma deoxidation method of chromium powder, comprising the following steps:

[0027] 1) Select the metal chromium block, remove the surface skin, oxide film and nitrogen film; then use the hydraulic coarse crusher with circulating water cooling device to mechanically crush the chromium block to make it into particles below 3mm;

[0028] 2) Using the low-temperature brittleness of chromium, immerse the metal chromium particles in liquid nitrogen, and perform low-temperature vibration grinding at the same time. The low-temperature vibration grinding uses nano-Al 2 o 3 with ZrO 2 The vibratory mill cylinder liner and grinding body made of mixed high-toughness ceramic materials are carried out for 3 hours;

[0029] 3) Wash the metal chromium powder ground by low-temperature liquid nitrogen three times with ethanol, each time with an amount of 600ml, and then use a vacuum system with filter paper to filter, and then in a vacuum oven, at 80°C and a vacuum of 94...

Embodiment 2

[0033] A hydrogen plasma deoxidation method of chromium powder, comprising the following steps:

[0034] 1) Select the metal chromium block, remove the surface skin, oxide film and nitrogen film; then use the hydraulic coarse crusher with circulating water cooling device to mechanically crush the chromium block to make it into particles below 3mm;

[0035] 2) Using the low-temperature brittleness of chromium, immerse the metal chromium particles in liquid nitrogen, and perform low-temperature vibration grinding at the same time. The low-temperature vibration grinding uses nano-Al 2 o 3 with ZrO 2 The vibrating mill cylinder liner and grinding body made of mixed high-toughness ceramic materials are carried out for 5 hours;

[0036] 3) The metallic chromium powder ground by low-temperature liquid nitrogen is washed three times with ethanol, each dosage is 500ml, and then filtered using a vacuum system with filter paper, and then in a vacuum oven at 80°C and a vacuum of 96.5kPa...

Embodiment 3

[0040] A hydrogen plasma deoxidation method of chromium powder, comprising the following steps:

[0041] 1) Select the metal chromium block, remove the surface skin, oxide film and nitrogen film; then use the hydraulic coarse crusher with circulating water cooling device to mechanically crush the chromium block to make it into particles below 3mm;

[0042] 2) Using the low-temperature brittleness of chromium, immerse the metal chromium particles in liquid nitrogen, and perform low-temperature vibration grinding at the same time. The low-temperature vibration grinding uses nano-Al 2 o 3 with ZrO 2 The vibratory mill cylinder liner and grinding body made of mixed high-toughness ceramic materials are carried out for 4 hours;

[0043] 3) The metal chromium powder ground by low-temperature liquid nitrogen is washed three times with ethanol, each dosage is 550ml, and then filtered using a vacuum system with filter paper, and then in a vacuum oven at 80°C and a vacuum of 95.5kPa D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com