Micro-porous metal organic framework material for methane and acetylene adsorption and storage, and preparation method of micro-porous metal organic framework material

A technology of metal-organic frameworks and organic frameworks, applied in chemical instruments and methods, alkali metal compounds, copper-organic compounds, etc., to achieve the effects of increased adsorption capacity, simple preparation process, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

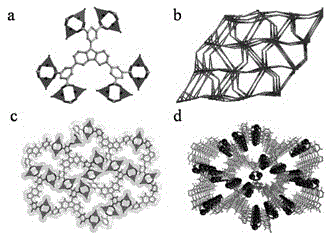

Image

Examples

Embodiment 1

[0030] (1) Dissolve 10g (50mmol) of 5-amino-isophthalic acid dimethyl ester into 225mL of hydrobromic acid solution with a mass concentration of 15%, stir and cool to 0°C, add dropwise 23mL of The aqueous solution of sodium nitrite of L carries out diazotization reaction, obtains diazonium salt solution;

[0031] (2) 9.8g cuprous bromide is dissolved in 90mL mass concentration and is in the hydrobromic acid solution of 15%, after being cooled to 0 ℃, in this solution, add dropwise the diazonium salt solution that step (1) obtains while stirring, React at 0°C for 30 minutes, and then react at room temperature for 12 hours. After the reaction, filter the organic layer and wash it repeatedly with water. Dissolve the organic layer in dichloromethane and wash with anhydrous MgSO 4 After drying and filtering, use petroleum ether and ethyl acetate (volume ratio 8:1) as the eluent to carry out column chromatography separation and purification to obtain 10.5 g of 5-bromo-dimethyl isoph...

Embodiment 2

[0045] The implementation of steps (1) to (8) in this example is the same as the implementation of steps (1) to (8) in Example 1.

[0046] (9) 2mg of 5,5',5"-(9H-carbazole-3,6,9-triyl)isophthalic acid obtained in step (8) and 2.916mg of Zn(NO 3 ) 2 2.5H 2 O was dissolved in 3mL N,N-dimethylacetamide (DMA), placed in a 5mL seed bottle, sealed and placed in an oven at 80°C for 72 hours. After taking it out, it was washed repeatedly with DMA to obtain a metal-organic framework material. .

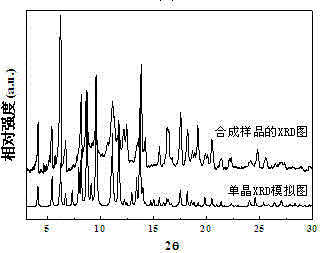

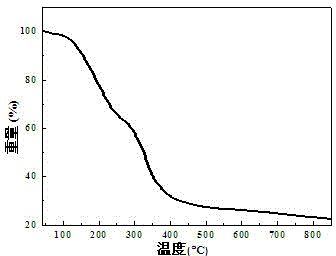

[0047] The metal-organic framework material obtained in this example was solvent-exchanged with acetone, and the solvent was exchanged at least ten times every fifteen minutes, and then activated at 0°C for 24 hours under vacuum conditions, and then activated at room temperature for 12 hours, and finally After activation at 100°C for 2.5 hours, a metal-organic framework material with unsaturated metal sites and open pores was obtained. Using Micromeritics ASAP 2020 specific surface area an...

Embodiment 3

[0049] The implementation of steps (1) to (8) in this example is the same as the implementation of steps (1) to (8) in Example 1.

[0050] (9) 2 mg of 5,5', 5"-(9H-carbazole-3,6,9-triyl) isophthalic acid obtained in step (8) and 2.916 mg of NiCl 2 Dissolve in N,N-diethylacetamide (DEF) / acetonitrile (3mL, volume ratio: 9:1), place in a 5mL seed bottle, seal it and place it in an oven at 80°C for 72h, take it out Repeated washing with DEF yielded metal-organic framework materials.

[0051] The metal-organic framework material obtained in this example was solvent-exchanged with acetone, and the solvent was exchanged at least ten times every fifteen minutes, and then activated at 0°C for 24 hours under vacuum conditions, and then activated at room temperature for 12 hours, and finally After activation at 100°C for 2.5 hours, a metal-organic framework material with unsaturated metal sites and open pores was obtained. The Micromeritics ASAP 2020 specific surface area analyzer was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com