Ceftiofur hydrochloride breast injection for dairy cow in dry period and preparation method thereof

A technology for ceftiofur hydrochloride and breast injection, which is applied in the directions of medical preparations containing active ingredients, pharmaceutical formulations, and emulsion delivery, etc., can solve problems such as short action time, achieve slow drug release, simple production process, The effect of avoiding cross infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Ceftiofur hydrochloride breast injection provided by the invention is a uniformly distributed preparation, and the specific preparation method comprises the following steps:

[0029] A. Let the vegetable oil (such as neutral soybean oil) cool after filtering and heat sterilization;

[0030] B. Take an appropriate amount of pretreated vegetable oil and add 0.5 to 5 g of glyceryl monostearate;

[0031] C. Heat at 60-80°C for 15-30 minutes, wait for glycerol monostearate to melt, stir evenly, cool to about 40°C, add 0.5-5g suspending agent (such as Span 80), 2.5-10g ceftiofur hydrochloride (particle size 5-10μm), and then add vegetable oil to a total of 100ml;

[0032] D. Grind evenly to prepare ceftiofur hydrochloride breast injection;

[0033] E. Put the medicine into the injection tube, seal it, sterilize it, inspect it with light, and pack it.

[0034] In the following examples, the detection method of the sedimentation particle size of the breast injection is as fo...

Embodiment 1

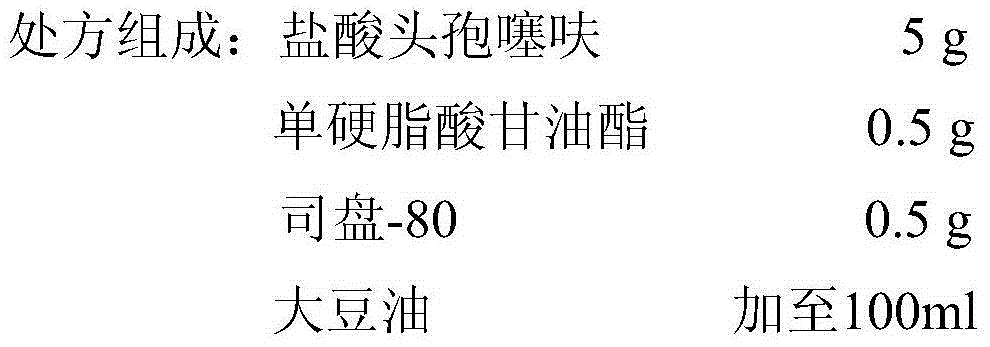

[0036] Embodiment 1, preparation of ceftiofur hydrochloride breast injection (dry milk period)

[0037]

[0038] The preparation method is as follows:

[0039] 1) Ultrafine pulverization of ceftiofur hydrochloride sterile powder to obtain ceftiofur hydrochloride sterile fine powder with a particle size of 5-10 μm;

[0040] 2) After the soybean oil is filtered and heat sterilized (sterilized at 160°C for 2 hours), put it at room temperature for later use;

[0041] 3) Take an appropriate amount of pretreated soybean oil (40%-60% of the total amount of soybean oil), add glyceryl monostearate; heat and stir (heat at 60°C for 15 minutes), wait for glyceryl monostearate Melt the ester, stir evenly, cool to 40°C, then add Span 80, ceftiofur hydrochloride, and add soybean oil to the full amount;

[0042] 4) Grind evenly in a sterile colloid mill to prepare ceftiofur hydrochloride breast injection.

[0043] The obtained ceftiofur hydrochloride breast injection (dry milk stage) is...

Embodiment 2

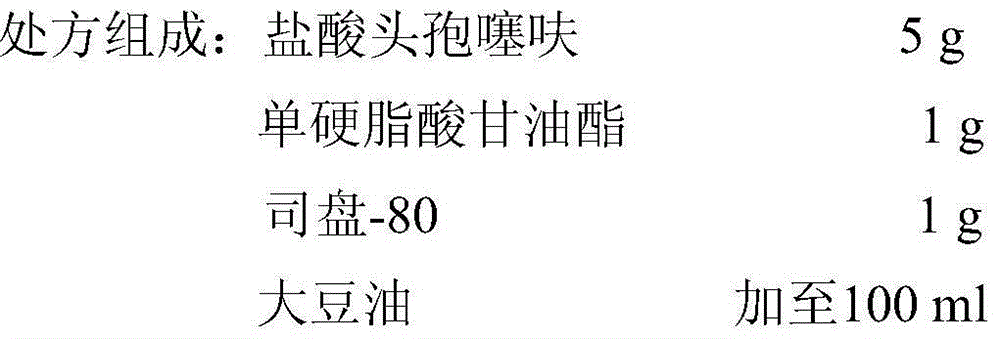

[0045] Embodiment 2, preparation of ceftiofur hydrochloride breast injection (dry milk period)

[0046]

[0047] The preparation method is as follows:

[0048] 1) Ultrafine pulverization of ceftiofur hydrochloride sterile powder to obtain ceftiofur hydrochloride sterile fine powder with a particle size of 5-10 μm;

[0049] 2) After the soybean oil is filtered and heat sterilized (sterilized at 150°C for 3 hours), put it at room temperature for later use;

[0050] 3) Take an appropriate amount of pretreated soybean oil (40%-60% of the total amount of soybean oil), add glyceryl monostearate; heat and stir (heating at 80°C for 30 minutes), wait for glyceryl monostearate Melt the ester, stir evenly, cool to 40°C, then add Span 80, ceftiofur hydrochloride, and add soybean oil to the full amount;

[0051] 4) Grind evenly in a sterile colloid mill to prepare ceftiofur hydrochloride breast injection.

[0052] The obtained ceftiofur hydrochloride breast injection (dry milk stage)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com