Crystalline silicon cell and manufacturing method thereof

A technology of crystalline silicon cells and manufacturing methods, which is applied in the field of solar cells, can solve problems such as low parallel resistance, unfavorable photoelectric conversion efficiency of crystalline silicon solar cells, and enhanced ability to conduct charges, so as to achieve parallel resistance improvement and photoelectric conversion efficiency improvement , the effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

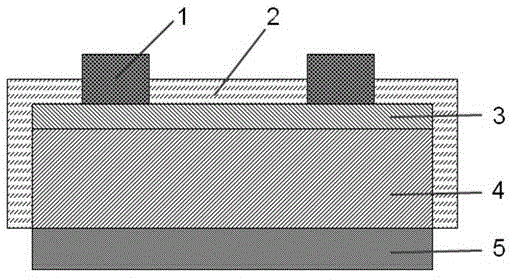

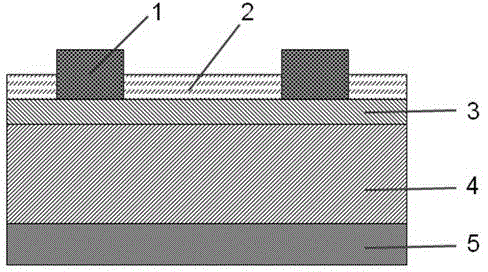

Image

Examples

Embodiment 1

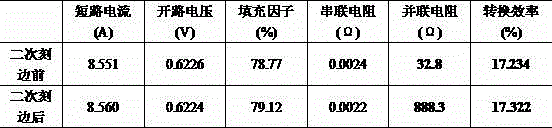

[0023] Embodiment 1: The manufacturing method of the crystalline silicon battery of the embodiment of the present invention, the specific implementation steps are as follows: polysilicon with an area of 156*156 is subjected to texturing, diffusion junction, edge cutting, phosphorus silicon glass removal, and silicon nitride anti-reflection deposition Layer, printed electrodes and sintering processes to obtain crystalline silicon solar cells, followed by a second edge-cutting process. Among them, the secondary edge cutting process adopts wet chemical etching, wets the dust-free cloth with 5-10% hydrofluoric acid solution, and then places the edge of the crystalline silicon cell on the dust-free cloth for 15-20 minutes Finally, the color at the edge of the crystalline silicon cell changes from blue to bright gray, and the silicon nitride layer is removed. Table 1 shows the electrical performance parameters of crystalline silicon solar cells before and after the second edge bev...

Embodiment 2

[0026] Embodiment 2: The manufacturing method of crystalline silicon cell, the specific implementation steps are as follows: polycrystalline silicon with an area of 156*156 is processed through texturing, diffusion junction, edge cutting, phosphorus silicon glass removal and silicon nitride anti-reflection layer deposition, followed by Secondary edge cutting process. Among them, the secondary edge cutting process adopts wet chemical etching, and the dust-free cloth is wetted in a mixed acid solution with a concentration of 65% nitric acid and a concentration of 5-10% hydrofluoric acid. Among them, the volume ratio of nitric acid to hydrofluoric acid 4:1, then place the edge of the crystalline silicon cell on a dust-free cloth, and after about 10 minutes, the color at the edge of the crystalline silicon cell changes from blue to bright gray, and the silicon nitride layer is removed. Finally, printed electrodes and sintering process to produce crystalline silicon solar cells. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com