High-strength high-corrosion-resistant nickel-based high-temperature alloy and solution and aging heat treatment method thereof

A nickel-based superalloy and solution aging technology, applied in the field of nickel-based superalloy, can solve the problems of lack of alloy composition control and performance optimization technology, lack of stable industrial production capacity, etc., and achieve the effect of low material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

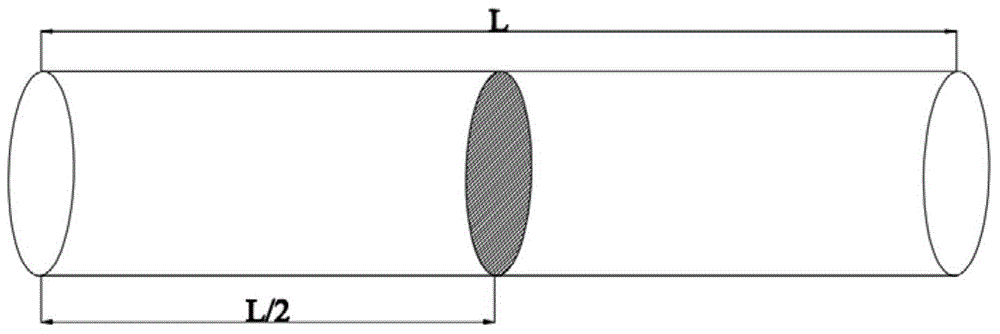

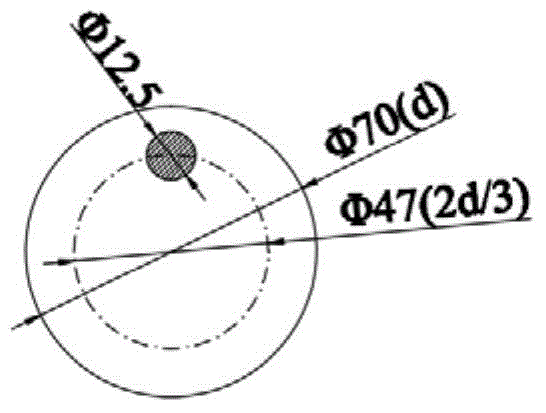

[0040] A novel high-strength and high-corrosion-resistant nickel-based superalloy and a solution aging heat treatment method thereof, comprising the following steps:

[0041] Step 1): 40% Ni, 21% Cr, 3.25% Mo, 2.25% Cu, 0.3% Al, 2.2% Ti, 0.01% C, 0.5% Mn, 0.01% Mg, the balance being Fe, added to the vacuum induction furnace for melting, vacuum induction melting and electroslag remelting to obtain alloy ingots, the composition of which is shown in Table 1 No.1 alloy;

[0042] Step 2): the alloy ingot is homogenized in a heat treatment furnace at 1180°C for 30 hours;

[0043] Step 3): After the homogenization treatment, the alloy ingot is forged at 1170°C and held for 1.5 hours, and then forged into a square billet by graded forging through 3 fires, and the deformation amount per fire is 50%;

[0044] Step 4): After hot forging, the billet is kept at 1120°C for 1.5 hours before rolling, and is hot-rolled to a bar through one heat, and the deformation amount of each pass is 40%,...

Embodiment 2

[0052] Step 1): 44% Ni, 21% Cr, 3.25% Mo, 2.25% Cu, 0.3% Al, 2.3% Ti, 0.01% C, 0.5% Mn, 0.01% Mg, the balance is Fe, added to the vacuum induction furnace for melting, vacuum induction melting and electroslag remelting, to obtain alloy ingots, the composition is shown in No.2 alloy in Table 1;

[0053] Step 2): the alloy ingot is homogenized in a heat treatment furnace at 1170° C. for a holding time of 40 hours;

[0054] Step 3): After the homogenization treatment, the alloy ingot is forged at 1160°C and held for 1.5 hours, and then forged into a square billet by graded forging through 4 fires, and the deformation amount per fire is 40%;

[0055] Step 4): After hot forging, the billet is kept at 1130°C for 1.5 hours before rolling, and is hot-rolled to a bar after one heat, and the deformation amount of each pass is 40%, and the bar is made;

[0056] Step 5): The bar obtained in step 3) is kept at 980°C for 70 minutes in a heat treatment furnace, then water-cooled, and then a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

| Room temperature tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com