Regenerated PA6 (polyamide 6)-base flame-retardant electric-insulating heat-conducting composite material, and preparation method and application thereof

A heat-conducting composite material, insulation and heat-conducting technology, applied in the field of recycled PA6-based flame retardant, heat-conducting composite materials, and insulation, can solve problems such as failure to achieve insulation, toxic and harmful gases, and non-compliance, and improve bond strength and flame retardancy Good, the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

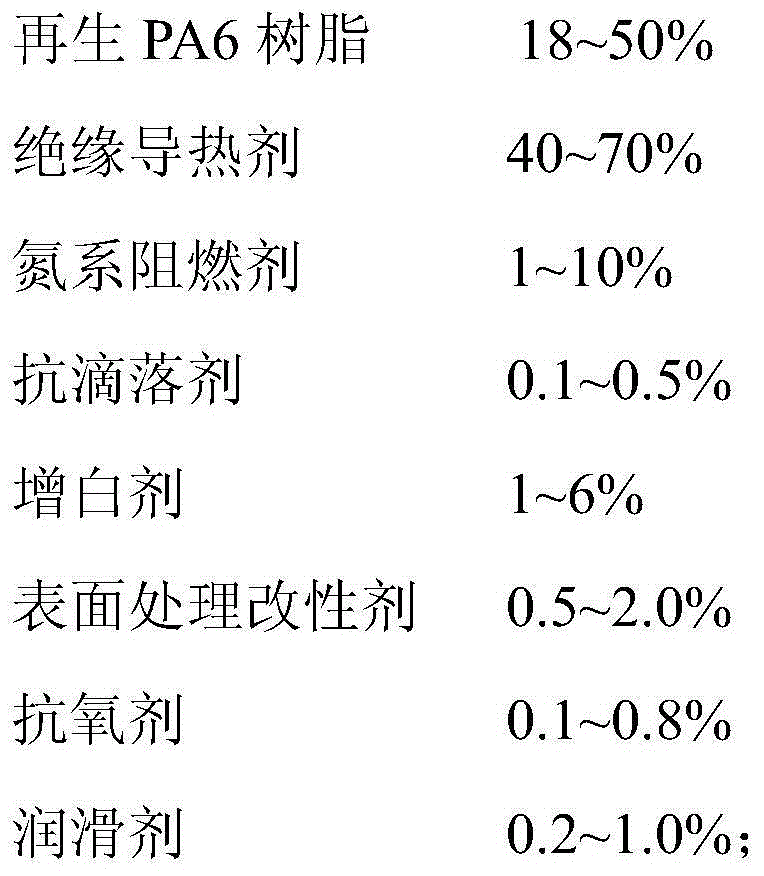

Method used

Image

Examples

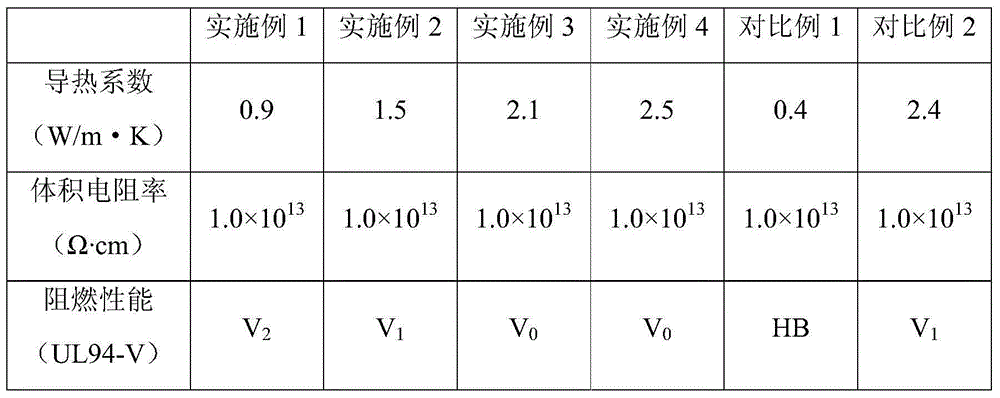

Embodiment 1

[0042] Prepare a recycled PA6-based flame-retardant, insulating, and thermally conductive composite material according to the following steps:

[0043] (1) Put 40kg of insulating heat-conducting agent magnesium hydroxide and 0.8kg of surface treatment modifier KH550 into a high-speed mixer at 90°C, stir (spindle speed 1300rpm) for 10 minutes, and dry at 100°C for 2 hours to obtain surface coating treatment Insulation and heat conduction agent;

[0044] (2) 49.2kg of recycled PA6 resin (relative viscosity 1.8-2.0), 5kg of nitrogen-based flame retardant melamine cyanurate (MC-25), 0.1kg of anti-dripping agent polytetrafluoroethylene (PTFE), 4kg of White agent titanium dioxide, 0.4kg antioxidant (antioxidant 1098 and antioxidant 168 compounded at a weight ratio of 1:1), 0.5kg lubricant silicone powder (E525) were placed in a high-speed mixer at 80 ° C (spindle speed 1300rpm) mixed for 5min, then the mixture was extruded at 200°C by a single-screw extruder, cooled, granulated and...

Embodiment 2

[0049] Prepare a regenerated PA6-based flame-retardant, insulating, and heat-conducting composite material according to the method of Example 1: the difference is only that the amount of the regenerated PA6 resin is changed to 34.2kg, and the insulating and heat-conducting agent is changed to 50kg magnesium hydroxide and 5kg aluminum nitride, Other components and quality remain unchanged. The performance test results of the obtained composite materials are shown in Table 1.

Embodiment 3

[0051] Prepare a regenerated PA6-based flame-retardant, insulating, and heat-conducting composite material according to the method of Example 1: the only difference is that the amount of the regenerated PA6 resin is changed to 19.2kg, and the insulating and heat-conducting agent is changed to 60kg magnesium hydroxide and 10kg aluminum nitride, Other components and quality remain unchanged. The performance test results of the obtained composite materials are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com