A 125°C irradiation cross-linked PE cable material for UL high-temperature electronic wires and its preparation method

A technology of electronic wire and cable material, which is applied in the field of 125°C irradiation cross-linked PE cable material for UL high-temperature electronic wire and its preparation, which can solve the problem of high price, low flame retardant efficiency of flame retardant, and reduced tensile strength of cable material , elongation at break and other issues, to achieve the effect of low price, increased smoothness and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

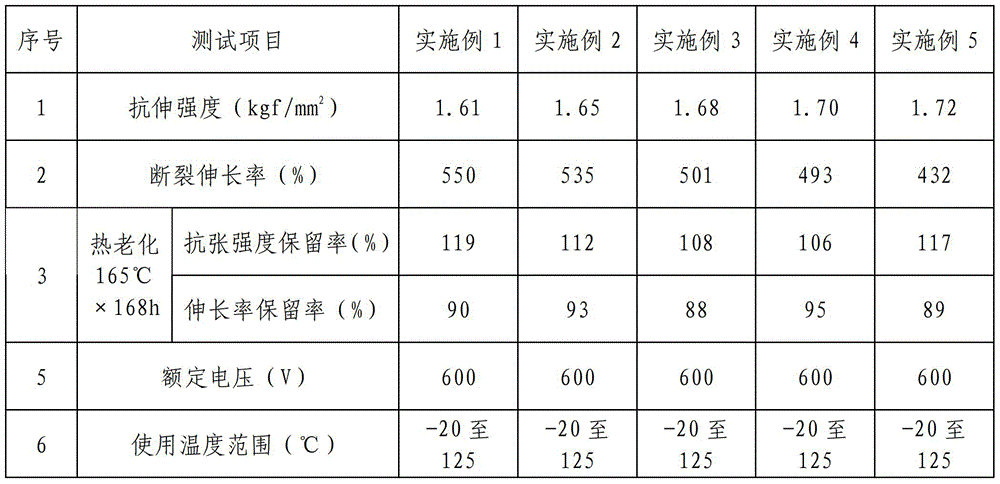

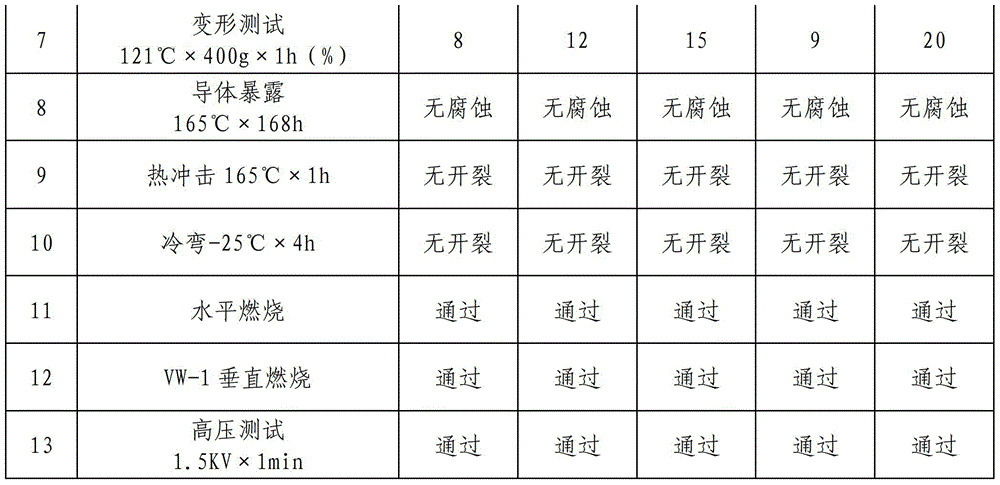

Examples

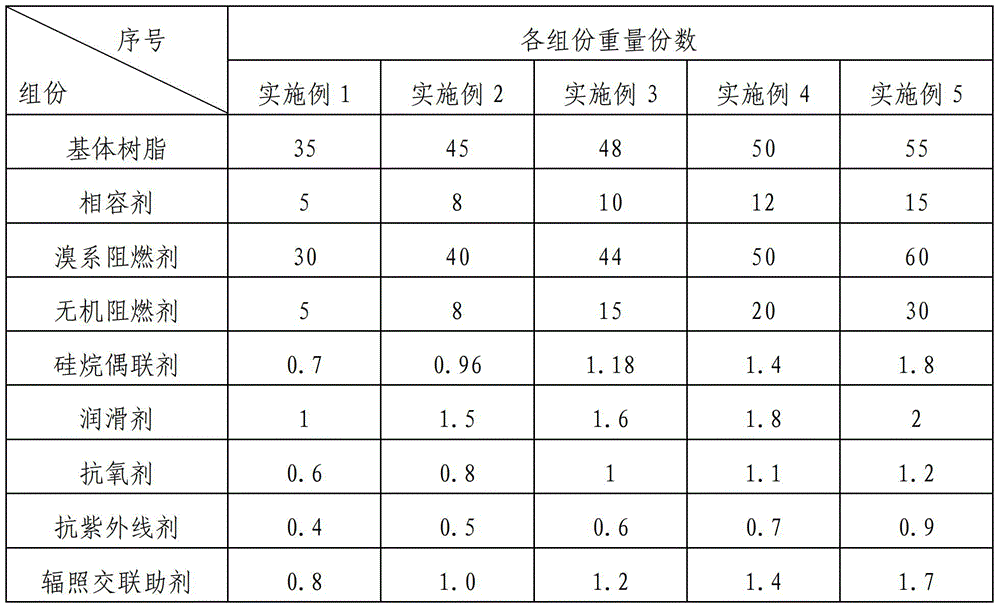

Embodiment 1

[0030] In Example 1: the weight parts of polyethylene A, polyethylene B, and ethylene-octene copolymer in the matrix resin are 12 parts, 17 parts, and 6 parts respectively; in the brominated flame retardant, decabromodiphenylethane The parts by weight of antimony trioxide and antimony trioxide are 22.5 parts and 7.5 parts respectively; the parts by weight of aluminum hydroxide and zinc borate in the inorganic flame retardant are 2.5 parts and 2.5 parts respectively; silicone masterbatch, The weight parts of polyethylene wax are 0.7 part and 0.3 part respectively; the main antioxidant and auxiliary antioxidant in the antioxidant are 0.3 part and 0.3 part respectively.

Embodiment 2

[0031] In Example 2: the weight parts of polyethylene A, polyethylene B, and ethylene-octene copolymer in the matrix resin are 16 parts, 22 parts, and 7 parts respectively; decabromodiphenylethane in the brominated flame retardant The parts by weight of antimony trioxide and antimony trioxide are 30 parts and 10 parts respectively; the parts by weight of aluminum hydroxide and zinc borate in the inorganic flame retardant are 4 parts and 4 parts respectively; the silicone masterbatch, The weight parts of the two polyethylene waxes are respectively 1.2 parts and 0.3 parts; the weight parts of the main antioxidant and the auxiliary antioxidant in the antioxidant are respectively 0.4 parts and 0.4 parts.

Embodiment 3

[0032] In Example 3: the weight parts of polyethylene A, polyethylene B, and ethylene-octene copolymer in the matrix resin are 17 parts, 23 parts, and 8 parts respectively; in the brominated flame retardant, decabromodiphenylethane The parts by weight of antimony trioxide and antimony trioxide are 33 parts and 11 parts respectively; the parts by weight of aluminum hydroxide and zinc borate in the inorganic flame retardant are 7.5 parts and 7.5 parts respectively; the silicone masterbatch, The weight parts of the two polyethylene waxes are respectively 1.2 parts and 0.4 parts; the weight parts of the main antioxidant and the auxiliary antioxidant in the antioxidant are respectively 0.5 parts and 0.5 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com