Asymmetric strong adhesive and easy to tear sensor and preparation method

A sensor, asymmetric technology, applied in the field of flexible sensors, can solve the problem of difficult to have strong adhesion and easy separation at the same time, and achieve the effect of improving the reuse rate, simple processing method, good peel resistance and easy peeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

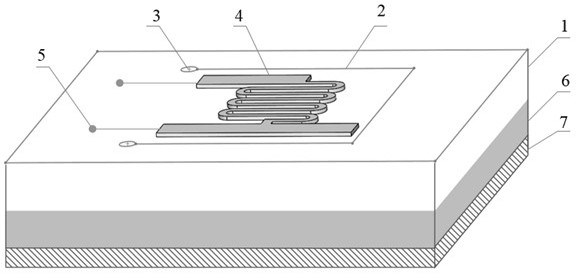

[0037] Using PIC hydrogel as a flexible substrate to prepare an asymmetric strong sticky and easy-to-tear sensor, the specific fabrication steps are as follows:

[0038] Step 1: To prepare PIC (conducting ion polymer) hydrogel film, first soak PIC powder in a centrifuge tube at 90°C with saline solution (2.5M) for 6 hours, then centrifuge at 5000~14000 rpm for 10 minutes, 3 times per hour , to remove the air bubbles in it to obtain a uniform PIC gel, and then keep the sample at 90 °C for 10 minutes to increase its fluidity, pour it into a polytetrafluoroethylene (PTFE) mold, and immediately compress it at room temperature for 20 Minutes to molding, take it out after molding, paste the acrylic adhesive layer on the bottom as the adhesive layer 6, and paste the release paper 7 on the bottom of the acrylic adhesive layer to protect the adhesive layer 6;

[0039] Step 2: The incision pattern can be designed by graphic design software such as AutoCAD or CorelDRAW, and the functiona...

Embodiment 2

[0044] Using PDMS (polydimethylsiloxane) as a flexible substrate to prepare an asymmetric strong adhesive and easy-to-tear sensor, the main difference from Example 1 lies in the preparation method of the substrate in step 1, which specifically includes the following steps:

[0045] Step 1: First, mix the PDMS (Kang Daoning 184) precursor solution and the solidification solution at a ratio of 10:1, and place it in a centrifuge at a speed of 500-2000 rpm for 5-10 minutes, and then inject PTFE (polytetrafluoroethylene) Ethylene) mold, vacuum defoaming for 5-10 minutes, put in an oven at 65°C and heat for 1-2 hours, after demolding, stick an acrylic adhesive layer on the bottom as the adhesive layer 6, and paste release paper 7 on the bottom of the acrylic adhesive layer Used to protect the adhesive layer 6;

[0046] Step 2: Form a functional incision 2 for adhesion regulation by laser cutting or punching process, clean the surface with industrial alcohol, and perform plasma treat...

Embodiment 3

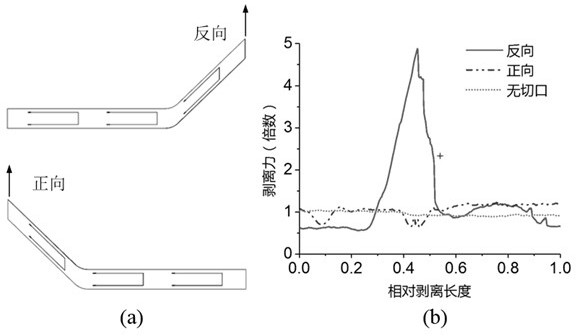

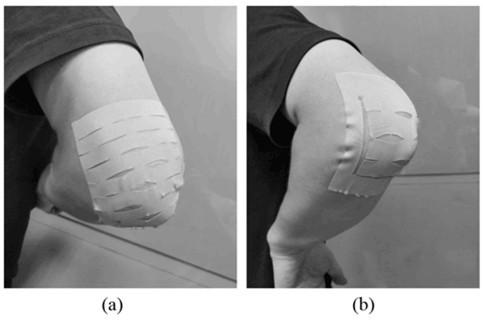

[0050] In order to improve the adaptability of the sensor to different viscosity requirements, the functional cutout (2) of the present invention is as follows Figure 5 shown, specific Figure 5 (a) is a hollowed-out asymmetric viscous sensor cutout pattern 21, Figure 5 (b) is a sensor cutout pattern 22 with a large deformation of a dotted line, Figure 5 (c) is a sensor cutout pattern 23 with both dotted line type and asymmetric stickiness; Figure 5 The hollow cut 21 in (a) not only has the characteristics of strong adhesion and easy tearing, but also can protect the surface protrusions of the sensed object, and can also monitor electronic devices and microstructures in real time; Figure 5 The dotted line incision 22 in (b) includes but is not limited to patterns such as isosceles triangle, rectangle, isosceles trapezoid, and semicircle. It is only necessary to ensure that the incision is oriented and not closed; the dotted line incision 22 can adapt to large deformatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com