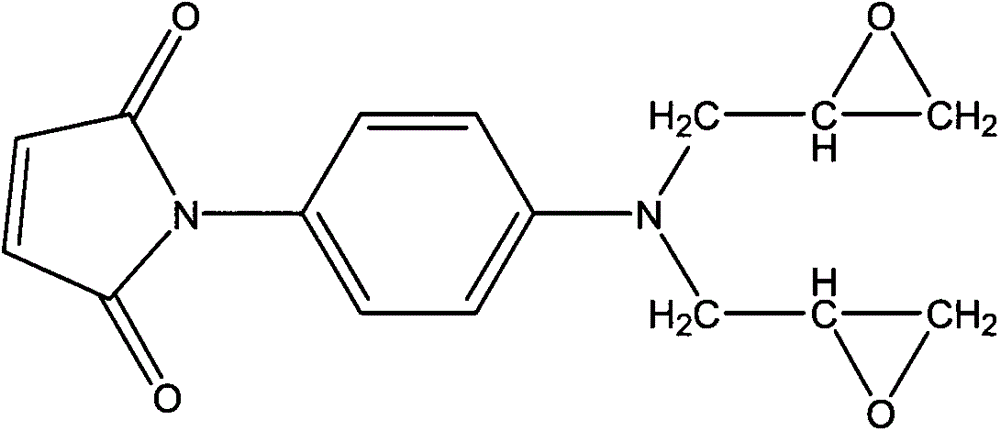

Method for preparing maleimide-containing epoxy resin curing agent

A technology of maleimide epoxy resin and curing agent, which is applied in organic chemistry and other fields, and can solve the problems of unseen modified product reports and patents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

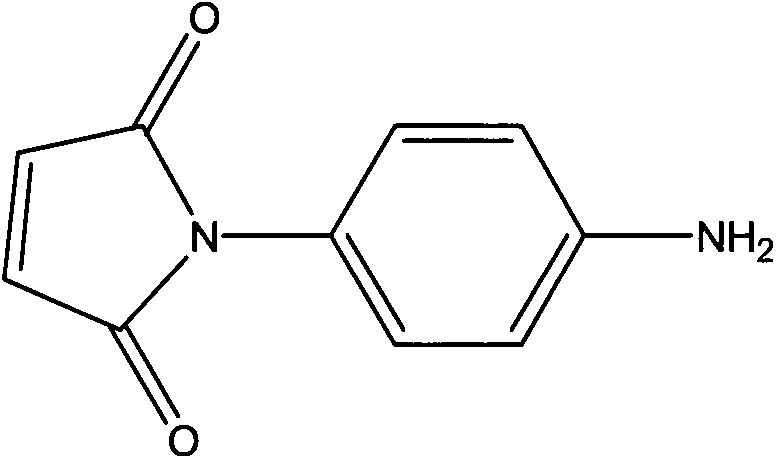

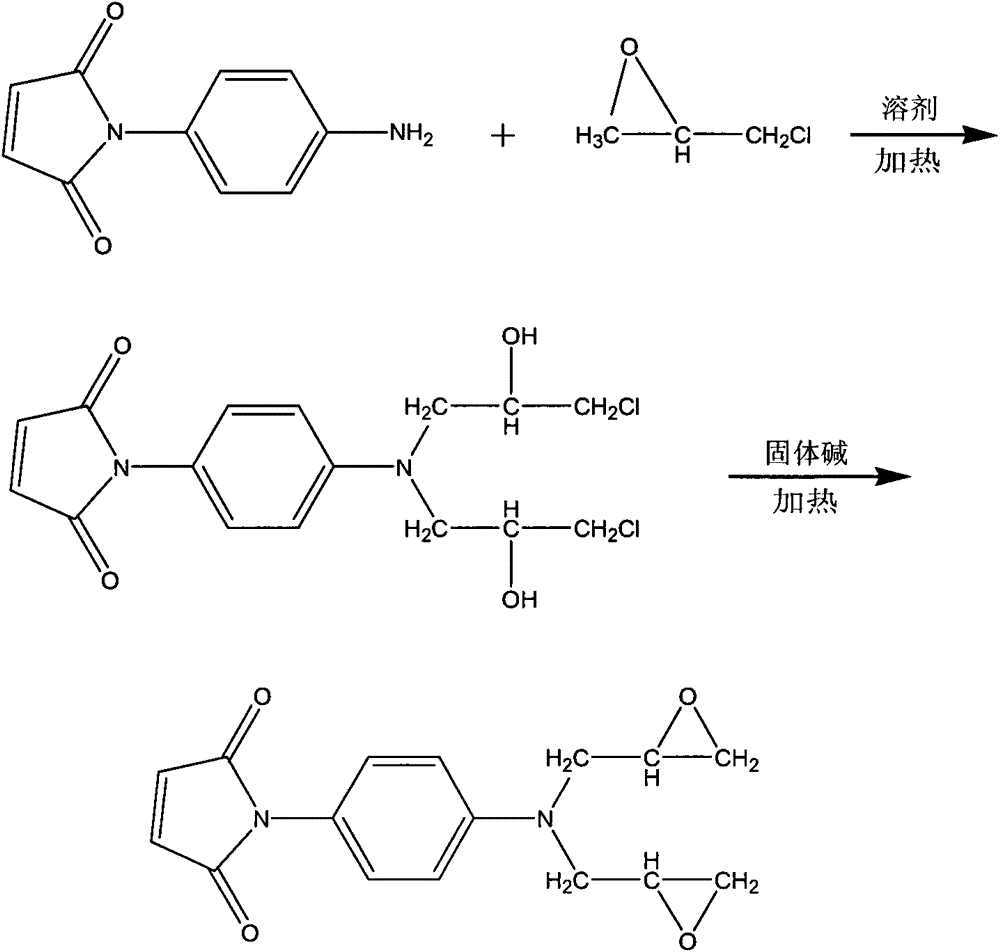

[0049] In the present embodiment, the preparation method that contains maleimide epoxy resin curing agent, its processing step is as follows successively:

[0050] (1) After dissolving 20.2g of N-(4-aminophenyl)maleimide and 0.25g of phase transfer catalyst benzyltriethylammonium chloride with 300ml of absolute ethanol, under the condition of nitrogen protection, the temperature was raised to 65°C, and then dropwise added 24.9 g of epichlorohydrin, and after the dropwise addition, the temperature was lowered to 55°C and reacted for 5 hours.

[0051] (2) Cool the reaction system to 30-40° C. and add 8.6 g of solid sodium hydroxide, then raise the temperature to 50° C. for 3 hours for ring closure reaction.

[0052] (3) After the reaction, cool down to room temperature, filter with suction, extract the filtrate with 3000ml of ethyl acetate, wash with deionized water for 3 times, and remove the ethyl acetate by rotary evaporation at 45°C to obtain the brown viscous target Produc...

Embodiment 2

[0054] In the present embodiment, the preparation method that contains maleimide epoxy resin curing agent, its processing step is as follows successively:

[0055] (1) After dissolving 20.2g of N-(4-aminophenyl)maleimide and 0.25g of phase transfer catalyst tetrabutylammonium chloride in 300ml of propanol, the temperature was raised to 65°C under nitrogen protection , and then 24.9 g of epichlorohydrin was added dropwise, and after the dropwise addition, the temperature was lowered to 55° C. and reacted for 4 hours.

[0056] (2) Cool the reaction system to 30-40°C and add 8.6g of solid sodium hydroxide, then raise the temperature to 50°C to carry out the ring-closing reaction for 4 hours.

[0057] (3) After the reaction, cool down to room temperature, filter with suction, extract the filtrate with 4200ml of ethyl acetate, wash with deionized water for 3 times, and remove the ethyl acetate by rotary evaporation at 45°C to obtain the brown viscous target Product—contains maleim...

Embodiment 3

[0059] In the present embodiment, the preparation method that contains maleimide epoxy resin curing agent, its processing step is as follows successively:

[0060] (1) After dissolving 20.2g of N-(4-aminophenyl)maleimide, 0.25g of phase transfer catalyst benzyltriethylammonium chloride with 360ml of absolute ethanol, under the condition of nitrogen protection, the temperature was raised After reaching 65°C, 29.9 g of epichlorohydrin was added dropwise, and after the dropwise addition, the temperature was lowered to 55°C and inverted for 6 hours.

[0061] (2) The temperature of the reaction system was lowered to 30-40° C. and 8.6 g of solid potassium hydroxide was added, and then the temperature was raised to 50° C. for 2 hours of ring closure reaction.

[0062] (3) After the reaction, cool down to room temperature, filter with suction, extract the filtrate with 3000ml of ethyl acetate, wash with deionized water for 3 times, and remove the ethyl acetate by rotary evaporation at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com