A kind of preparation method of crystallization calcium lactate

A calcium lactate crystallization technology, applied in organic chemical methods, separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve problems such as unsuitable for separation and purification of fermentation broth, unfavorable for large-scale production and use, and low crystallinity. Achieve good industrial application prospects, save post-processing costs, and achieve the effect of large crystal size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

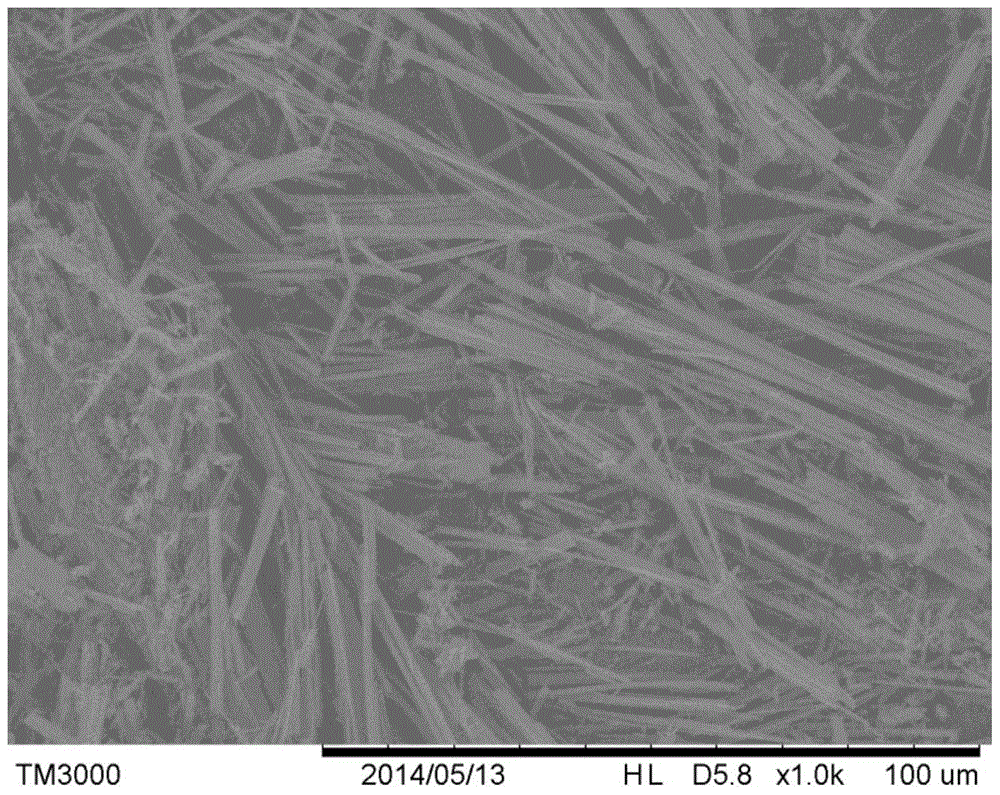

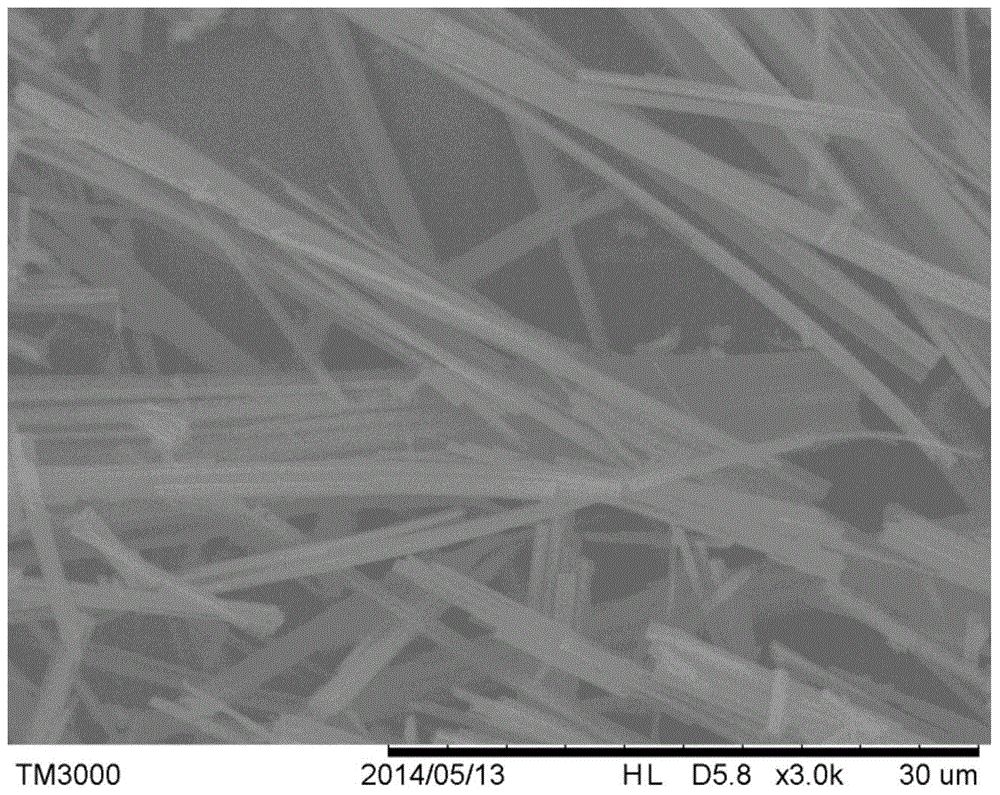

[0024] Add activated carbon to the L-calcium lactate fermentation broth with a concentration of 0.147g / mL, and continuously stir for decolorization and deodorization; after filtration, the filtrate is transferred to a crystallizer, and the pH is adjusted to 6.0. Acetone was added at 40° C. at a rate of 10% / hr of the volume of the fermentation broth. Stop adding acetone when its volume consumption is 2 times of the total volume; then filter and separate after cooling down to 20°C at a cooling rate of 5°C / hr, wash with a mixture of acetone and water (volume ratio) of 1:1, and obtain the The crystalline product was dried at 30°C for 4 hours at an absolute pressure of 0.009 MPa. The final crystal main particle size is 19.33 μm, and the crystallization process single-pass yield is 86.0% (molar yield). The drying loss of the product is 24.6%, which is the pentahydrate of L-calcium lactate.

Embodiment 2

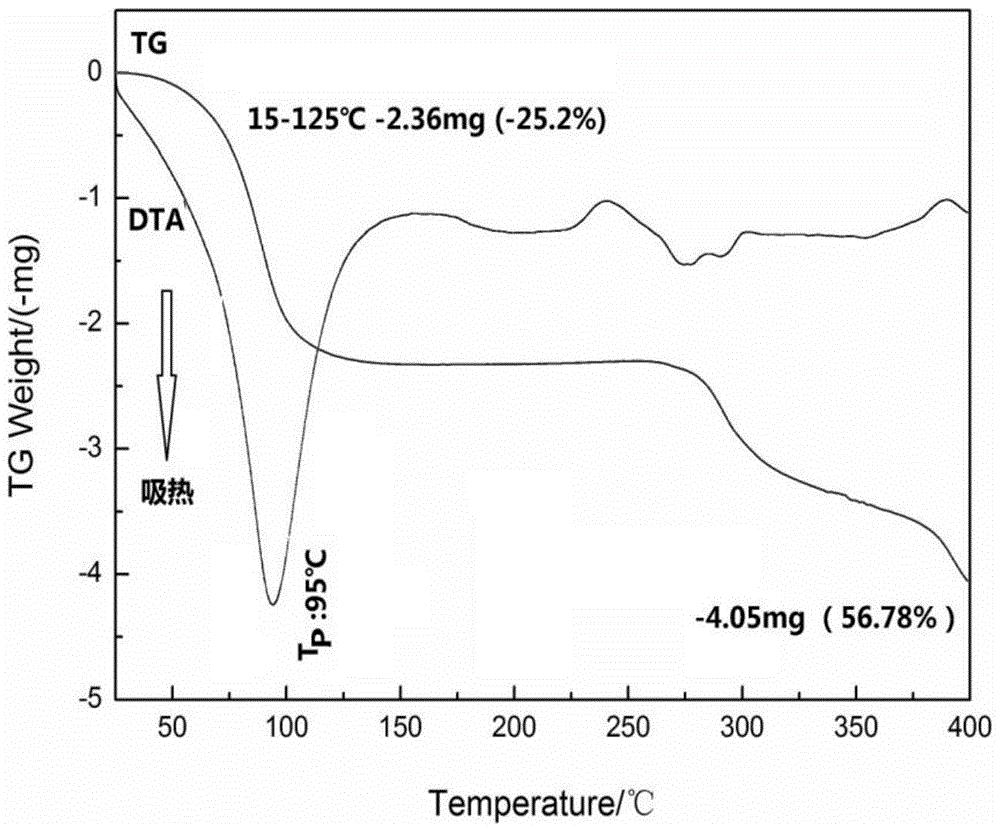

[0026] Add activated carbon to the 0.155g / ml L-calcium lactate fermented liquid, and stir continuously for decolorization and deodorization; after filtering, move the filtrate into a crystallizer, and adjust the pH to 8.0. Methanol was added at 45°C at a rate of 60% / hr of the volume of the fermentation broth. When the volume consumption is 8 times of the total volume, stop adding methanol; then cool down to 5°C at a cooling rate of 10°C / hr, then filter and separate, wash with a mixture of methanol and water (volume ratio) of 1:2, and the obtained The crystalline product was dried at 45°C for 4 hours at an absolute pressure of 0.1 MPa. The final crystal main particle size is 21.30 μm, and the crystallization process single-pass yield is 82.3% (molar yield). The drying loss of the product is 25.2%, which is the pentahydrate of L-calcium lactate.

Embodiment 3

[0028] Add activated carbon to the 0.405g / ml L-calcium lactate fermented liquid, and stir continuously for decolorization and deodorization; after filtering, move the filtrate into a crystallizer, and adjust the pH to 7.3. Add ethanol at 60° C. at a rate of 90% / hr of the volume of the fermentation broth. When the volume consumption is 3.5 times of the total volume, stop adding ethanol; then cool down to 7°C at a cooling rate of 8°C / hr, filter and separate, wash with ethanol, and store the obtained crystal product at 35°C with an absolute pressure of 0.008MPa Dry for 4 hours. The main particle size of the final crystal is 19.60 μm, and the single-pass yield of the crystallization process is 87.4% (molar yield). The product has a weight loss on drying of 19.4%, which is the trihydrate of L-calcium lactate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com