Method for synthesizing SOD type sodalite in low-temperature controllable manner

A sodalite and low-temperature technology, which is applied in the direction of aluminum silicate and silicate, can solve the problems of complex process and achieve the effect of simple synthesis process, uniform particle size and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh 2.5g sodium hydroxide and dissolve in 20mL deionized water, add 1.385g Al 2 (SO 4 ) 3 Mix well and continue to add 1.18g Na 2 SiO 3 9H 2 O, to obtain a mixed solution, 0.2 g of diatomaceous earth was added to the above mixed solution under stirring conditions, and the mixture was continuously stirred for 2 hours to form a white uniform emulsion.

[0027] Seal the resulting mixture in a hydrothermal reaction kettle, let it stand at 80°C for 24 hours, and after natural cooling, wash it with water by centrifugation or Buchner funnel filtration, separate it, and then dry it in a blast drying oven at 60°C for 12 hours , Take out and grind to get the product.

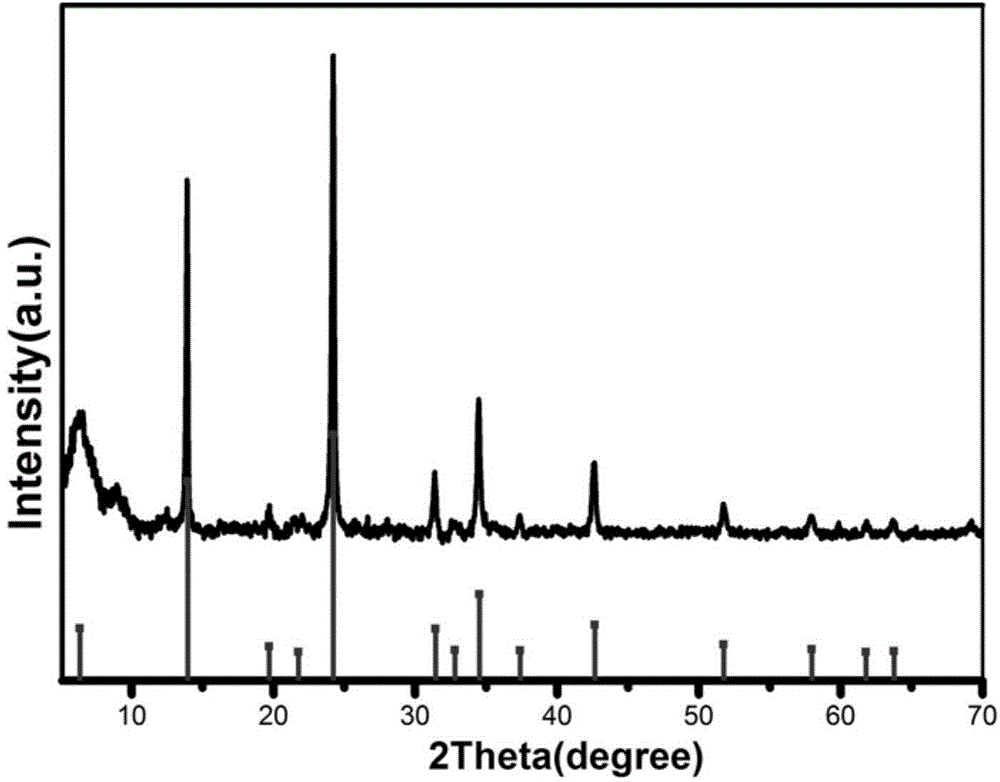

[0028] figure 1 It is the XRD figure of the product synthesized in this embodiment, as can be seen from the figure at 13.8 °, 24.3 °, 31.4 °, 34.5 °, the peaks that appear at 42.6 ° correspond to the standard cards of sodalite one by one, and it can be judged that the product is square Sodalite structure,...

Embodiment 2

[0031] Weigh 2.5g sodium hydroxide and dissolve in 20mL deionized water, add 1.955g AlCl 3 Mix well and continue to add 1.18g Na 2 SiO 3 9H 2 O, to obtain a mixed solution, 0.2 g of diatomaceous earth was added to the above mixed solution under stirring conditions, and the mixture was continuously stirred for 2 hours to form a white uniform emulsion.

[0032] Seal the resulting mixture in a hydrothermal reaction kettle, let it stand at 80°C for 24 hours, and after natural cooling, wash it with water by centrifugation or Buchner funnel filtration, separate it, and then dry it in a blast drying oven at 60°C for 12 hours , Take out and grind to get SOD type sodalite.

Embodiment 3

[0034] Weigh 2.5g sodium hydroxide and dissolve in 20mL deionized water, add 3.04g Al(NO 3 ) 3 9H 2 o

[0035] Mix well and continue to add 1.18g Na 2 SiO 3 9H 2 O, to obtain a mixed solution, 0.2 g of diatomaceous earth was added to the above mixed solution under stirring conditions, and the mixture was continuously stirred for 2 hours to form a white uniform emulsion.

[0036] The resulting mixture was sealed in a 50mL hydrothermal reaction kettle lined with a polytetrafluoroethylene pad, and left to react at 80°C for 24 hours. After natural cooling, it was washed with water by centrifugal or Buchner funnel filtration, separated, and then in Dry it in a blast oven at 60°C for 12 hours, take it out and grind it to get SOD type sodalite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com