Sand-proof railway vehicle

A technology for rail vehicles and wind and sand protection, applied in the field of rail vehicles, can solve the problems of flexibility, wear resistance, aging resistance and interlayer adhesion that cannot meet the requirements of wind and sand protection, decreased flexibility, and electrical system damage. Achieve excellent aging resistance, good overall flexibility, and excellent cold resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

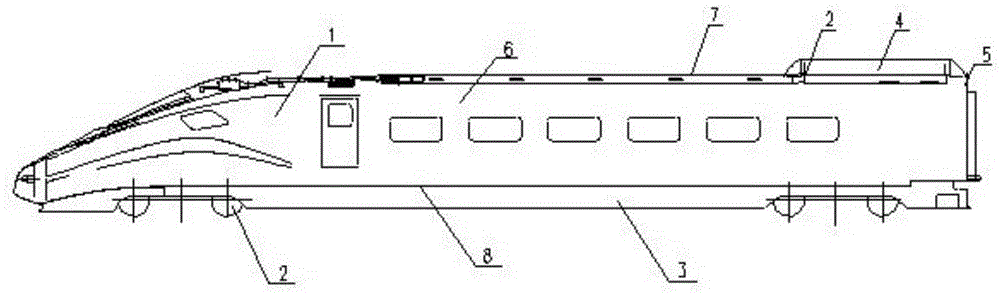

[0024] Such as figure 1 As shown, a kind of anti-wind and sand rail vehicle provided by the present invention includes an aluminum alloy car body 1, a bogie 2, an equipment cabin 3, an air conditioning and ventilation system 4, and the like.

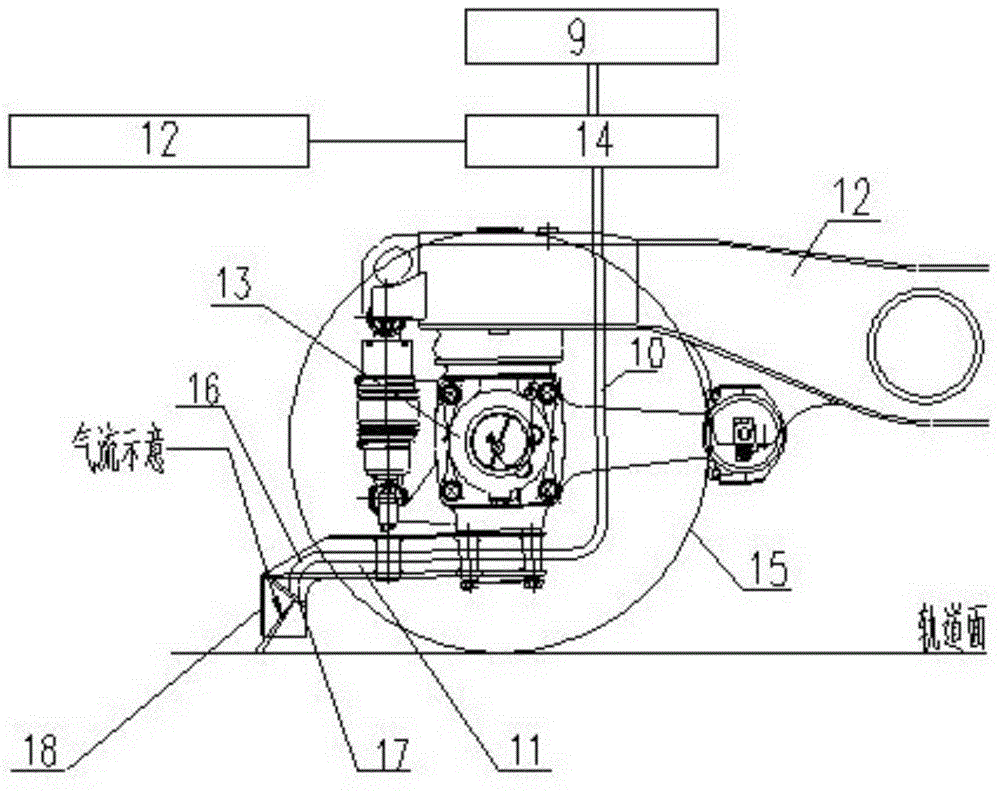

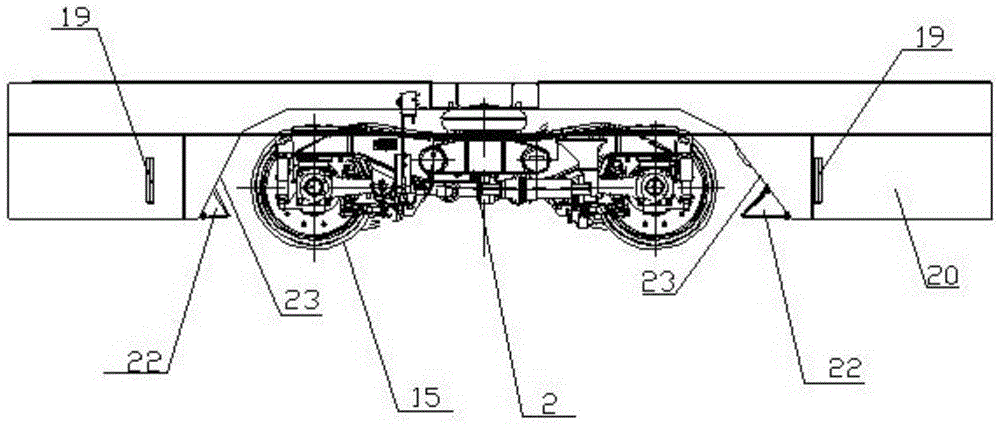

[0025] Wherein, the vehicle body 1 includes an end wall 5 , a side wall 6 , a roof 7 and an underframe 8 . The bogie 2 includes frame, traction system, braking system, primary suspension system, secondary suspension system, axles, axle boxes, wheel sets, etc. The traction system includes traction motors, gearboxes and other components, and the braking system includes brake clips Calipers, brake discs and other components. The air-conditioning ventilation system 4 includes a top-mounted air-conditioning unit installed on the roof. The air-conditioning unit sends the treated air into the passenger compartme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com