A kind of dendrimer/polyacrylic acid composite film and preparation method thereof

A technology of dendrimer and polyacrylic acid, which is applied in the field of dendrimer/polyacrylic acid composite film and its preparation, can solve the problems of poor water resistance and mechanical properties of polyacrylic acid film, achieve controllable film diameter and improve mechanical stability , The effect of broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

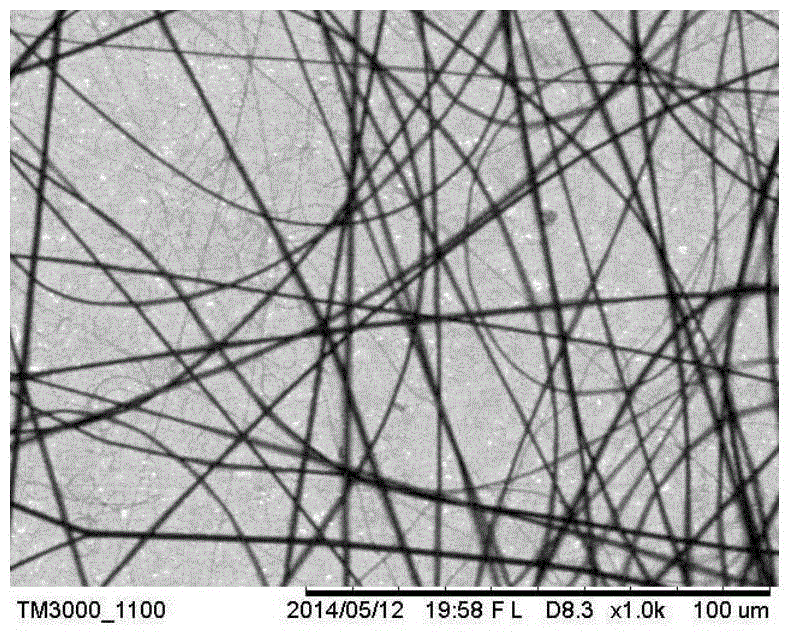

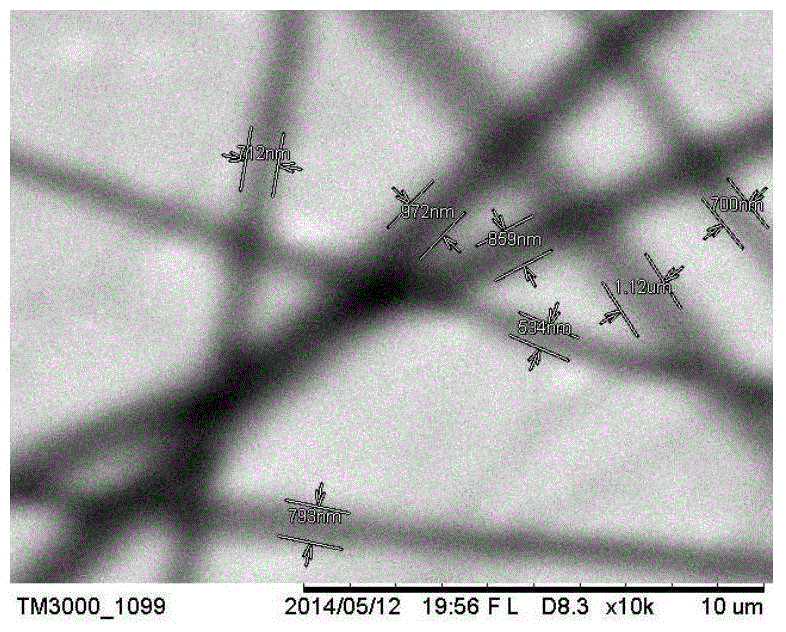

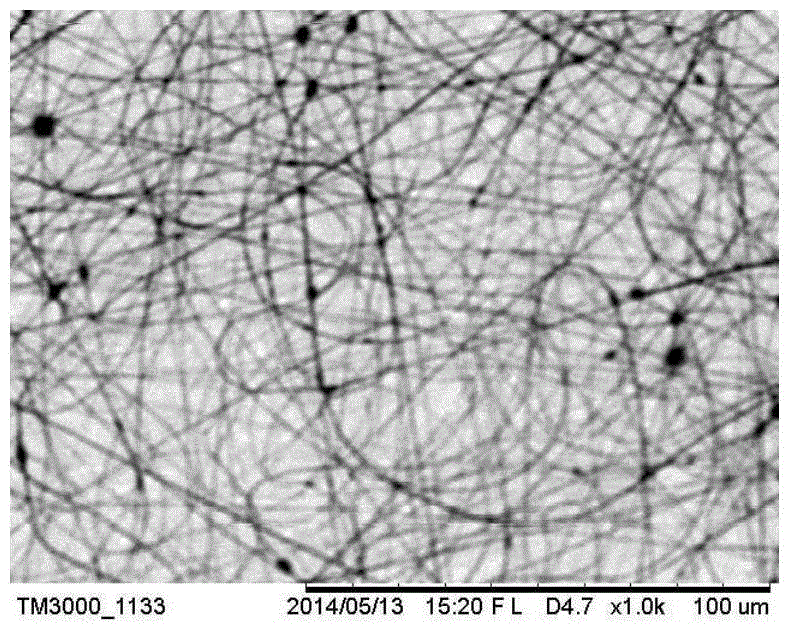

Image

Examples

Embodiment 1

[0033] A dendrimer / polyacrylic acid composite membrane, the molar ratio of polyacrylic acid and dendrimers in the composite membrane is 2132, the fiber average diameter of the composite membrane is 622nm, and the water flux of the composite membrane is measured at 0.7MPa 420g / (m 2 h).

[0034] A kind of preparation method of dendrimer / polyacrylic acid composite film, concrete steps are as follows:

[0035] Step 1. Prepare the dendrimers to a concentration of 1.7494×10 -5 mol L -1 The 4.5 generation polyamide-amine dendrimer aqueous solution;

[0036] Step 2, preparing polyacrylic acid into an ethanol solution with a concentration of 15.0 wt %;

[0037] Step 3, cooling 0.5 ml of the dendrimer aqueous solution in step 1 and 2.735 g of the polyacrylic acid ethanol solution in step 2 to room temperature and then mixing, and mixing evenly to obtain a mixed solution;

[0038] Step 4. Prepare the mixed solution obtained in step 3 into a film by electrospinning technology; put th...

Embodiment 2

[0041] A dendrimer / polyacrylic acid composite membrane, the molar ratio of polyacrylic acid and dendrimers in the composite membrane is 1162, the fiber average diameter of the composite membrane is 548nm, and the water flux of the composite membrane is measured at 0.7MPa 442g / (m 2 h).

[0042] A kind of preparation method of dendrimer / polyacrylic acid composite film, concrete steps are as follows:

[0043] Step 1. Prepare the dendrimers to a concentration of 1.7494×10 -5 mol L -1 The 4.5 generation polyamide-amine dendrimer aqueous solution;

[0044] Step 2, preparing polyacrylic acid into an ethanol solution with a concentration of 15.4 wt %;

[0045] Step 3, cooling 1.0ml of the dendrimer aqueous solution in step 1 and 2.903g of the polyacrylic acid ethanol solution in step 2 to room temperature and mixing, and mixing evenly to obtain a mixed solution;

[0046]Step 4. Prepare the mixed solution obtained in step 3 into a film by electrospinning technology; put the mixed ...

Embodiment 3

[0049] A dendrimer / polyacrylic acid composite membrane, the molar ratio of polyacrylic acid and dendrimers in the composite membrane is 4114, the fiber average diameter of the composite membrane is 673nm, and the water flux of the composite membrane is measured at 0.7MPa 431g / (m 2 h).

[0050] A kind of preparation method of dendrimer / polyacrylic acid composite film, concrete steps are as follows:

[0051] Step 1. Prepare the dendrimers to a concentration of 1.2187×10 -5 mol L -1 The 5.0th generation polyamide-amine dendrimer aqueous solution;

[0052] Step 2, preparing polyacrylic acid into an ethanol solution with a concentration of 15.4 wt %;

[0053] Step 3. Mix 0.5 ml of the dendrimer aqueous solution in step 1 and 3.581 g of polyacrylic acid ethanol solution in step 2 after cooling to room temperature, and mix evenly to obtain a mixed solution;

[0054] Step 4. Prepare the mixed solution obtained in step 3 into a film by electrospinning technology; put the mixed sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com