A kind of anti-biological pollution composite reverse osmosis membrane and preparation method thereof

An anti-biological fouling, reverse osmosis membrane technology, applied in reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problem of poor anti-biological fouling, low water flux, and reduced reverse osmosis membrane flushing in the polyamide desalination layer. frequency and other issues, to achieve good antibacterial and hydrophilic properties, widened flow channels, and excellent adsorption properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

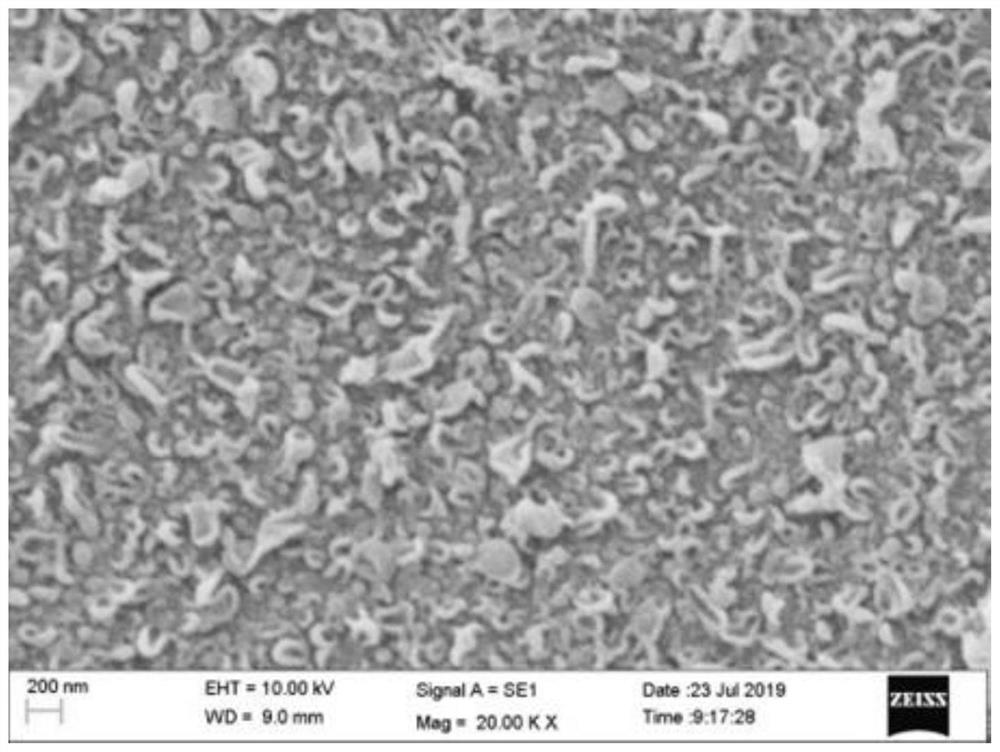

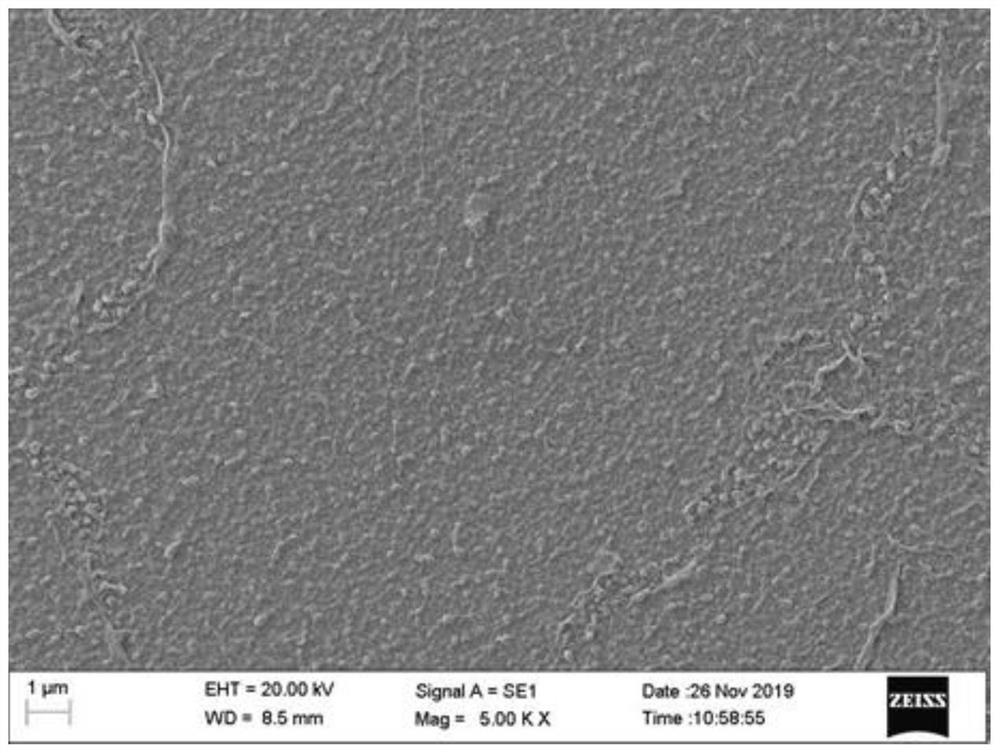

Image

Examples

Embodiment 1

[0029]The preparation of an anti biological pollution composite reverse osmosis membrane is as follows:

[0030] (1) Weigh 10g of clay mineral montmorillonite and disperse it in deionized water, add 2G of guanidine modifier (guanidine acetic acid) and mix it evenly by ultrasonic, then add ammonia drop by drop until the solution pH = 8 ~ 9, raise the temperature to 35 ℃ under stirring conditions for reaction for 2h, then filter the mixture, wash it with ethanol to medium, freeze-dry and grind it to obtain modified clay minerals for standby;

[0031] (2) First dissolve 20g citric acid and 10g sodium hydroxide in deionized water and mix evenly to prepare acid binding agent, then successively add 20g m-phenylenediamine, 1g dopamine and 1g modified clay minerals into the above acid binding agent, dilute to 1000g with deionized water and disperse by ultrasonic for 30min to form modified aqueous phase solution for standby;

[0032] (3) Weigh 1g of homobenzoyl chloride and dissolve it in ...

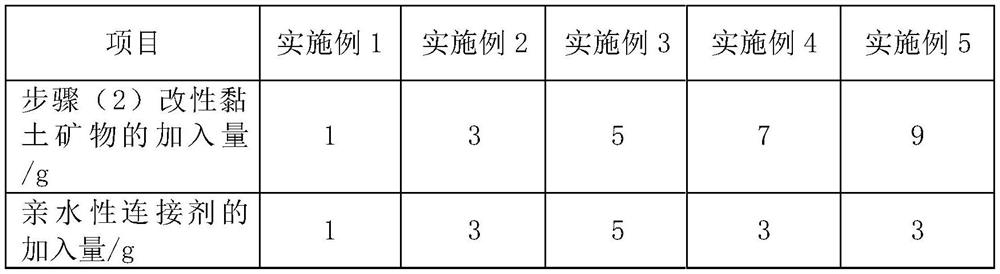

Embodiment 2~5

[0037] The preparation method of anti biological pollution composite reverse osmosis membrane in examples 2 ~ 5 is basically the same as that in example 1, except that the addition amount of modified clay mineral and hydrophilic linker added in step (2) is different, as shown in Table 1:

[0038] Table 1

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com