A kind of reverse osmosis membrane with polyvinylpyrrolidone surface modification and preparation method thereof

A technology of polyvinylpyrrolidone and reverse osmosis membrane, applied in the direction of reverse osmosis, semipermeable membrane separation, chemical instruments and methods, etc., can solve the problem of easy loss of polyvinylpyrrolidone, achieve good anti-pollution performance and low flux drop rate , the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

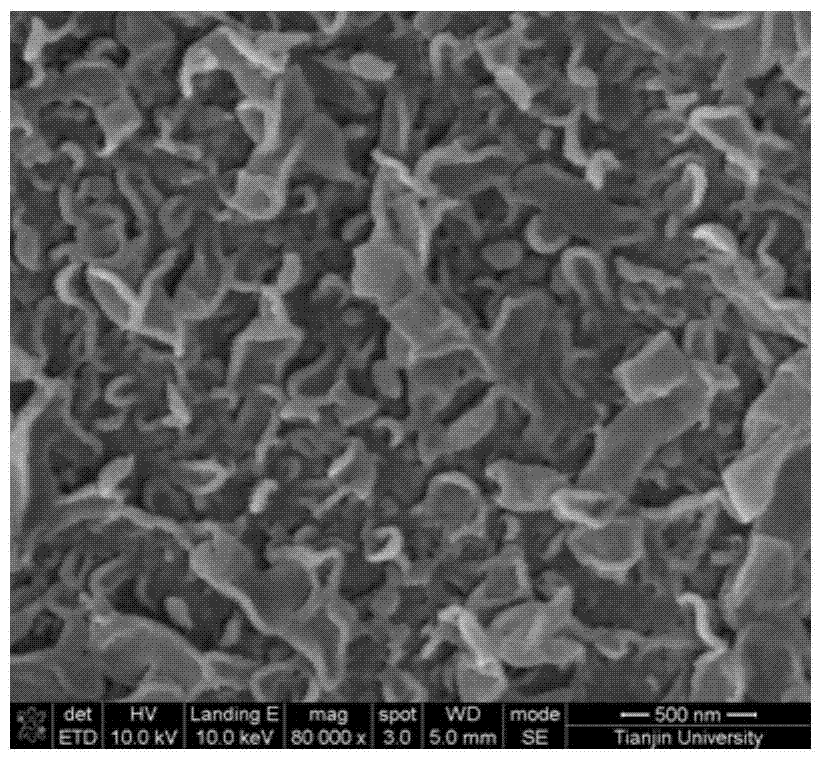

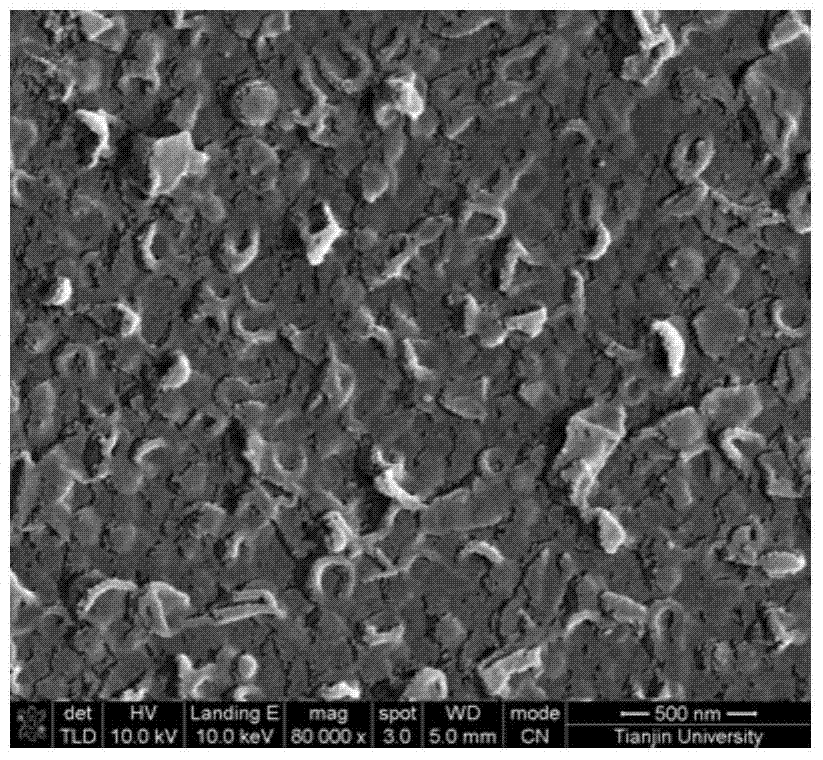

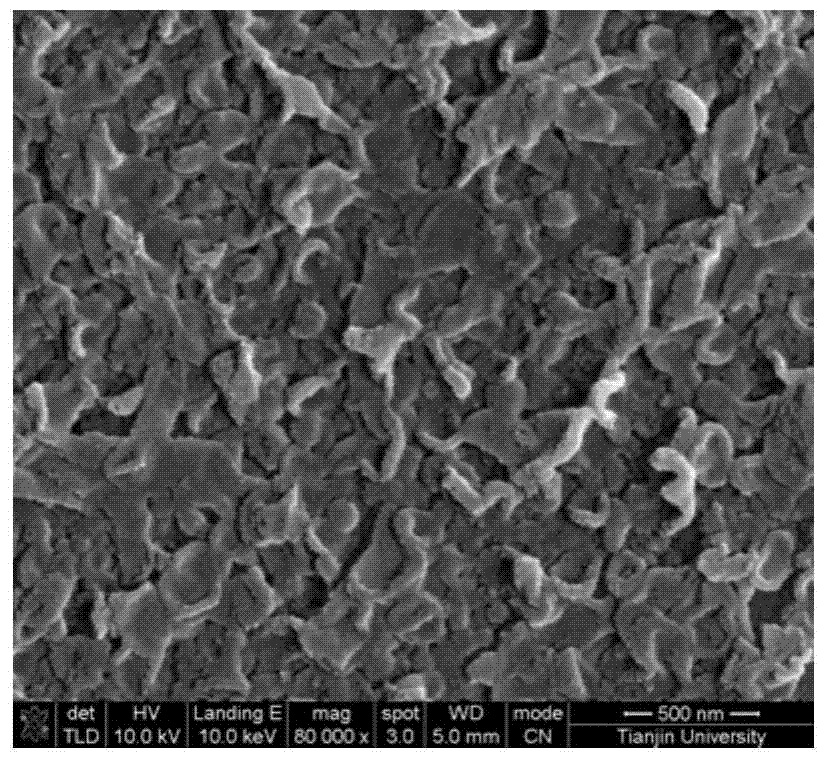

Image

Examples

Embodiment 1

[0023] (1) Fix the aromatic polyamide composite reverse osmosis membrane with a size of 15 × 13 cm between two plexiglass frames and a rectangular hollow silica gel pad. The rectangular hollow silica gel pad has the same size as the plexiglass frame, and deionized water and Isopropanol fully rinses the surface of the reverse osmosis membrane;

[0024] (2) Prepare 25 mL of ferric chloride aqueous solution with a concentration of 0.1 mg / mL, quickly pour the aqueous solution on the membrane surface, so that the aqueous solution completely wets the membrane surface;

[0025] (3) Prepare 25 mL of tannic acid aqueous solution with a concentration of 0.2 mg / mL and 25 mL of a polyethyleneimine aqueous solution with a concentration of 0.1 mg / mL, pour it on the reverse osmosis membrane surface containing the ferric chloride aqueous solution, and shake it slowly to make it fully mixed;

[0026] (4) pour off the solution on the membrane surface, fully rinse the membrane surface with deio...

Embodiment 2

[0037] (1) Fix an aromatic polyamide composite reverse osmosis membrane with a size of 30 × 26 cm between two plexiglass frames and a rectangular hollow silica gel pad. The rectangular hollow silica gel pad has the same size as the plexiglass frame. Use deionized water and Isopropanol fully rinses the surface of the reverse osmosis membrane;

[0038] (2) Prepare 75 mL of ferric chloride aqueous solution with a concentration of 0.5 mg / mL, and quickly pour the aqueous solution on the membrane surface so that the aqueous solution completely wets the membrane surface;

[0039] (3) Prepare 75mL concentration of 1.0mg / mL tannic acid aqueous solution and 75mL concentration of 1.2mg / mL polyethylene polyamine aqueous solution, pour it on the reverse osmosis membrane surface containing ferric chloride aqueous solution, shake slowly to make it fully mixed;

[0040] (4) pour off the solution on the membrane surface, fully rinse the membrane surface with deionized water;

[0041](5) Prep...

Embodiment 3

[0047] (1) Fix the aromatic polyamide composite reverse osmosis membrane with a size of 50 × 40 cm between two plexiglass frames and a rectangular hollow silica gel pad. The size of the rectangular hollow silica gel pad is the same as that of the plexiglass frame. Isopropanol fully rinses the surface of the reverse osmosis membrane;

[0048] (2) Prepare 180 mL of ferric chloride aqueous solution with a concentration of 0.4 mg / mL, quickly pour the aqueous solution on the membrane surface, so that the aqueous solution completely wets the membrane surface;

[0049] (3) Prepare 180mL concentration of 0.6mg / mL tannic acid aqueous solution and 180mL concentration of 0.90mg / mL tetraethylenepentamine aqueous solution, pour it on the reverse osmosis membrane surface containing ferric chloride aqueous solution, shake slowly to make it fully mixed;

[0050] (4) pour off the solution on the membrane surface, fully rinse the membrane surface with deionized water;

[0051] (5) Prepare 200...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com