A cyclodextrin-modified polyamide film composite membrane, its preparation and application

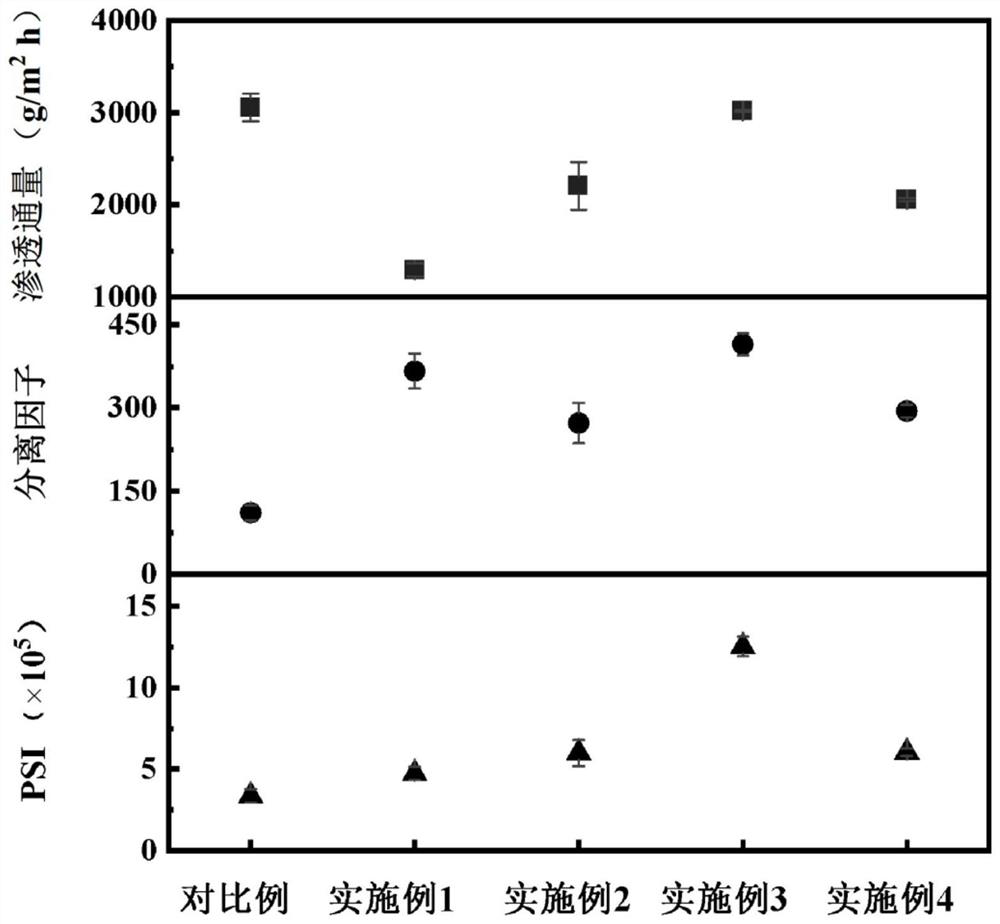

A cyclodextrin and composite membrane technology, applied in the field of membrane separation, can solve problems such as poor separation effect of polyamide composite membrane, achieve good pervaporation alcohol-water separation performance, improve hydrophilicity, and improve the effect of separation factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A kind of preparation method of the polyamide composite film of cyclodextrin modification provided by the invention, comprises the steps:

[0031] (1) Soak the polymer base film in the polyamine aqueous solution, take it out after fully soaking, and obtain the treated polymer base film;

[0032] (2) contacting the polymer base film treated in step (1) with the polyacyl chloride solution, so that the interfacial polymerization reaction of the polyamine and the polyacyl chloride occurs to obtain a polyamide composite film;

[0033] (3) Transfer the composite membrane obtained in step (2) to soak in an aqueous solution of cyclodextrin, so that the residual polyacyl chloride on the surface of the composite membrane and the cyclodextrin in the aqueous solution of cyclodextrin undergo a secondary interfacial polymerization reaction, which The esterification reaction between the polyacyl chloride and the hydroxyl group in the cyclodextrin molecule generates polyester; or the c...

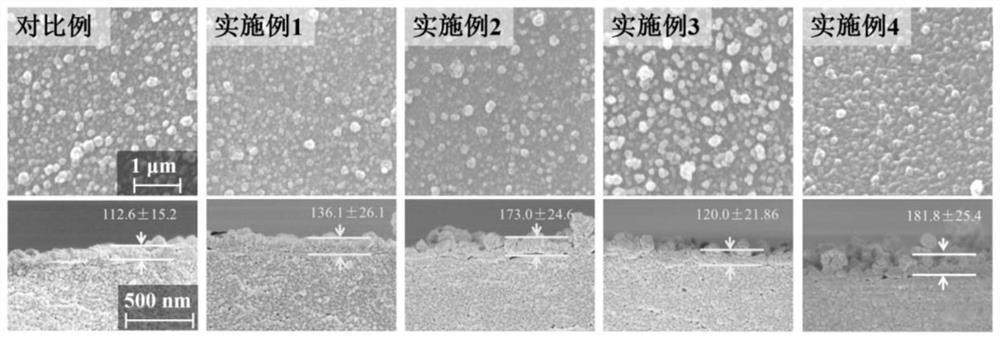

Embodiment 1

[0076] The polymer base membrane of the polyamide composite membrane prepared in this embodiment is a polyacrylonitrile hollow fiber ultrafiltration membrane. The preparation process of this composite film comprises the following steps:

[0077] (1) Basement membrane hydrolysis: same as Comparative Example 1.

[0078] (2) Soak the water phase: same as Comparative Example 1.

[0079] (3) Immersion oil phase: same as Comparative Example 1.

[0080] (4) Secondary interfacial polymerization: the composite membrane obtained in step (3) was transferred to an aqueous solution of β-cyclodextrin (pH 12, mass fraction 2%), soaked for 20 min, and then rinsed with water. Among them, β-cyclodextrin is abbreviated as β-CD, which is a raw material purchased from the market; its schematic structural formula is:

[0081]

Embodiment 2

[0083] The polymer base membrane of the polyamide composite membrane prepared in this embodiment is a polyacrylonitrile hollow fiber ultrafiltration membrane. The preparation process of this composite film comprises the following steps:

[0084](1) Synthesis of aminated cyclodextrin: first prepare an aqueous solution of KOH / cyclodextrin (molar ratio 120 / 7), heat it to 50° C., and then add excess ammonia water. Next, the temperature of the solution was raised to 60°C. Slowly add epichlorohydrin in an equimolar amount to ammonia water dropwise into the above solution. After the reaction was carried out for 1 hour, the solution was left to cool, and then the pH was adjusted to neutral with concentrated sulfuric acid. The mixture was concentrated by a rotary evaporator, and then washed sequentially with sufficient ethanol and methanol to remove inorganic salts and by-products. The final product was dried overnight in a vacuum oven at 55 °C and named β-CD-NH 4 Oh.

[0085] (2)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com