Antibacterial composite reverse osmosis membrane and preparation method thereof

A technology of reverse osmosis membrane and compound, applied in the field of membrane separation, can solve the problems of restricting the popularization and application of polyamide composite reverse osmosis membrane, increasing operating cost and energy consumption, reducing system production efficiency, etc., and achieving excellent anti-pollution performance and low cost , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] This embodiment provides an antibacterial composite reverse osmosis membrane, including a non-woven base layer, a porous support layer, and a separation layer;

[0096] The non-woven fabric base layer is polyester non-woven fabric, and its thickness is 120 μm;

[0097] The thickness of the porous support layer is 35 μm;

[0098] The separation layer has a thickness of 0.25 μm.

[0099] The present embodiment also provides a method for preparing an antibacterial composite reverse osmosis membrane, which specifically includes the following steps:

[0100] 1) Preparation of porous support layer:

[0101] 1.1) 10g of diallyl bisphenol sulfur, 15g of 4,4-dihydroxydiphenylsulfone, 25g of difluorodiphenylsulfone were added to 300g of N-methylpyrrolidone / toluene mixed solvent (mixing weight ratio 2.5:1), add 17.5g of anhydrous potassium carbonate, heat up to 160°C at a rate of 10°C / min, stir at 300r / min for 8h, after the reaction, pour the solution into deionized water, and ...

Embodiment 2

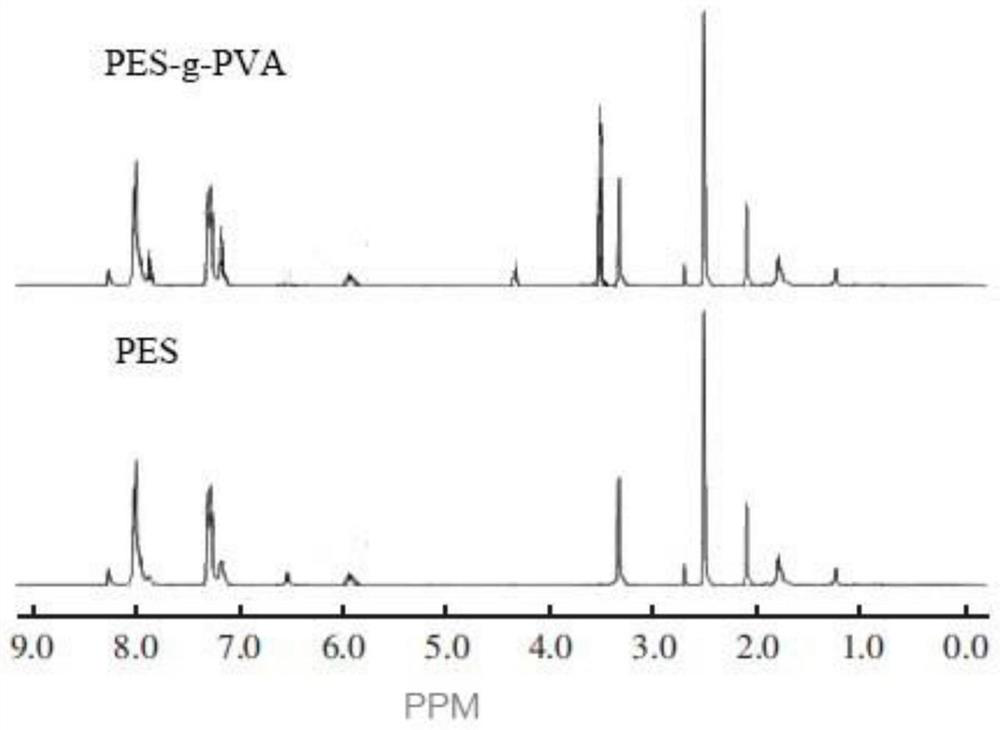

[0112] This example provides another antibacterial composite reverse osmosis membrane, and the preparation method is basically the same as that in Example 1, except that in this example, in step 3) of preparing the polyethersulfone / polyvinyl alcohol blend membrane, the The addition amount of the base polyvinyl alcohol is 1 g, that is, the added weight ratio of polyethersulfone and sulfhydryl polyvinyl alcohol is 1:0.1, and the graft ratio of the obtained polyethersulfone / polyvinyl alcohol graft copolymer is 16.7 %.

Embodiment 3

[0114] This example provides another antibacterial composite reverse osmosis membrane, and the preparation method is basically the same as that in Example 1, except that in this example, in step 3) of preparing the polyethersulfone / polyvinyl alcohol blend membrane, the The addition amount of the base polyvinyl alcohol is 2g, that is, the added weight ratio of polyether sulfone and sulfhydryl polyvinyl alcohol is 1:0.2, and the graft ratio of the obtained polyether sulfone / polyvinyl alcohol graft copolymer is 18.9 %.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com