A kind of anti-fouling polyamide composite film and preparation method thereof

A pollution-resistant, polyamide technology, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve the problems of good pollution resistance, achieve short production cycle, simple preparation process, high water flux and salt interception rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

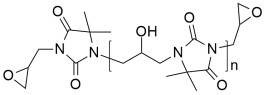

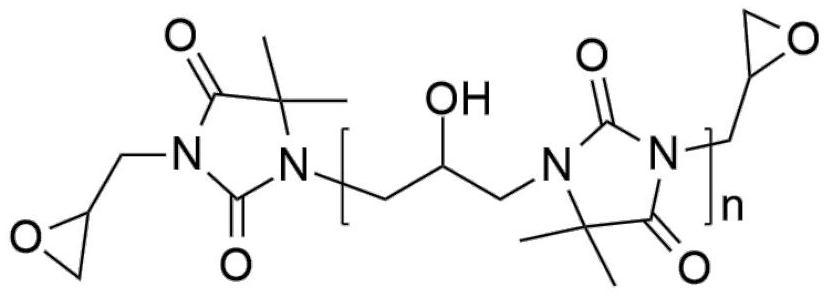

[0032] A pollution-resistant polyamide composite membrane, comprising a non-woven fabric layer, a polysulfone support layer, a polyamide layer and a pollution-resistant layer arranged in sequence, and the pollution-resistant layer is composed of dimethylhydantoin epoxy resin and unreacted A functional layer formed of a cross-linked polymer obtained through a cross-linking reaction of amine groups. Here dimethylhydantoin epoxy resin can be purchased from Sinopec Baling Petrochemical Co., Ltd.

[0033] The pollution-resistant polyamide composite membrane was prepared according to the following steps:

[0034] Prepare the anti-pollution solution, specifically: take 0.2 g of dimethylhydantoin epoxy resin and add it to 99.8 g of ethanol, stir until completely dissolved to obtain the anti-pollution solution;

[0035] Film making, comprises the following steps:

[0036] To make the substrate, specifically to arrange the non-woven fabric layer and the polysulfone support layer in se...

Embodiment 2

[0043] A kind of pollution-resistant polyamide composite membrane, differs from embodiment 1 in that:

[0044] In the prepared anti-pollution solution, weigh 0.4 g of dimethylhydantoin epoxy resin and add it to 99.6 g of ethanol, and stir until completely dissolved.

Embodiment 3

[0046] A kind of pollution-resistant polyamide composite membrane, differs from embodiment 1 in that:

[0047] In the prepared anti-pollution solution, 0.6 g of dimethylhydantoin epoxy resin was weighed and added to 99.4 g of ethanol, and stirred until completely dissolved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com